Prepare site • prepare burner • mount burner, Model 601gas burner — instruction manual, Prepare burner and components – Carlin 601GAS Inst Manual User Manual

Page 10

Model 601GAS burner — Instruction manual

Carlin part number MN601GAS Rev. 04/24/09

– 10 –

Where appliance instructions differ from this manual, follow the appliance instructions.

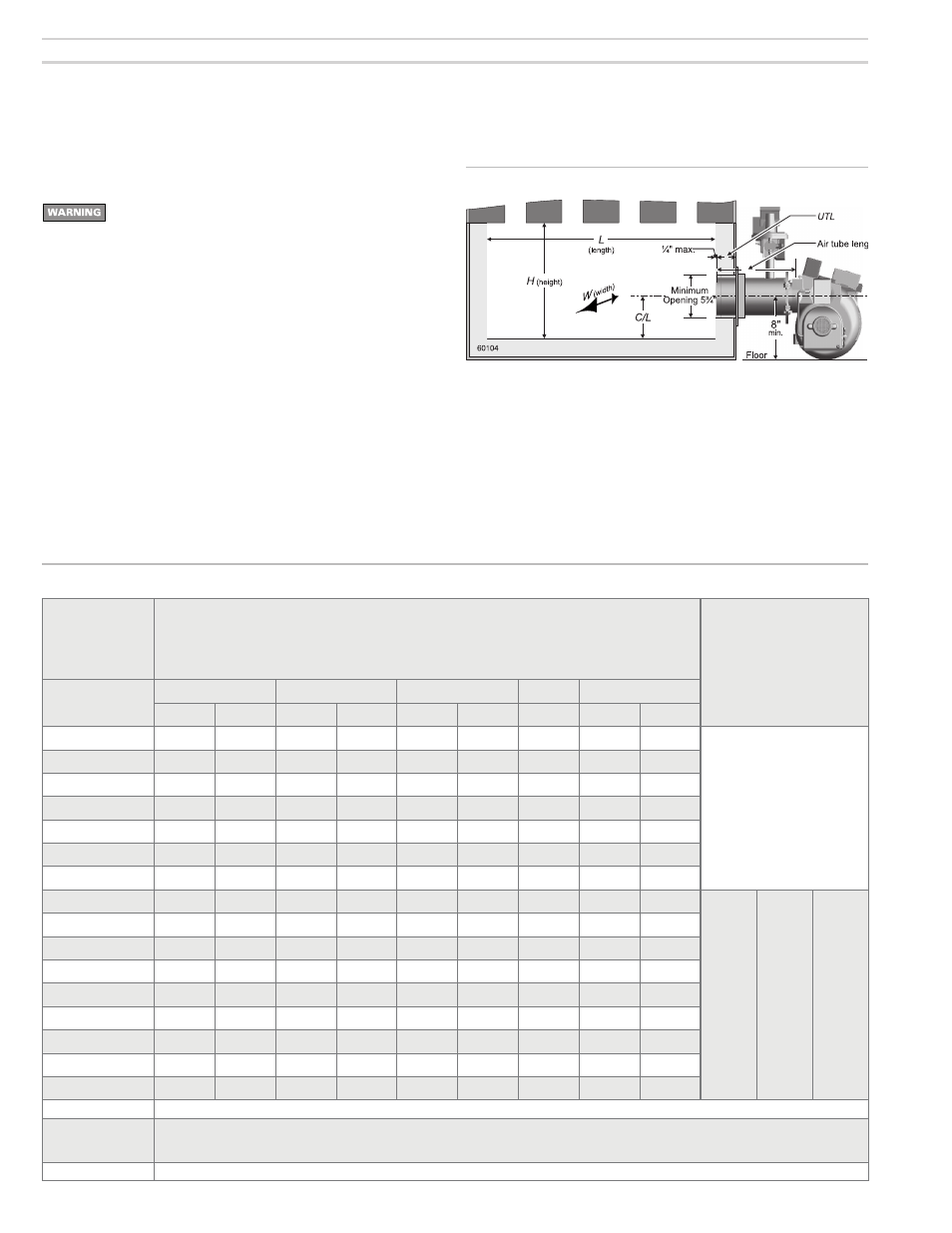

Figure 3b Chamber dimensions & tube configurations

Table 1b Minimum combustion chamber dimenions (see Figure 3b)

Prepare burner and components

Do not install or operate the burner if any component is damaged

or if burner does not comply with the specifications of Table 1b

and other guidelines in this manual.

Combustion chamber minimum dimensions

• For applications that have not been specifically tested (OEM applications),

verify that the combustion chamber provides the minimum dimensions

shown in Table 1b and Figure 3b. For specific OEM applications, the

appliance testing ensures suitability of the chamber.

• Chamber dimensions may be larger than listed in Table 1b, but should not

be excessively large.

Air tube insertion length (UTL)

• Usable air tube length (UTL) is the distance from mounting flange to end

of air tube. Verify that the end of the air tube will be flush with, or no more

than ¼ inch short of, the inside of the appliance combustion chamber front

wall when the burner is mounted. See Figure 3b and Table 1b for further

information.

Input

Note 1

Minimum chamber dimensions

Inches (Notes 1, 2, 3)

(VC = min. diam. of vertical cylinder chamber)

“Dry” means chamber surfaces refractory lined

“Wet” means water-back chamber surfaces, with no refractory covering

UTL

Air tube

insertion length

Btuh

L

W

C/L

H

VC

Dry

Wet

Dry

Wet

Dry

Wet

Wet

Dry

Wet

700,000

18

22

16

18

7.5

8.5

19

16

22

Welded flange:

Burners with welded flange have fixed

usable tube length (UTL) set for the

appliance application. Verify length is

correct for the application.

Adjustable flange:

Burners with adjustable flange:

Usable tube length (UTL) varies with air

tube length (see below).

750,000

19

23

16

18

7.5

8.5

19

17

23

800,000

20

24

17

19

8.0

9.0

20

18

24

850,000

20

24

17

19

8.0

9.0

20

18

24

900,000

22

27

17

19

8.0

9.0

20

20

27

950,000

24

29

17

19

8.0

9.0

20

22

29

1,000,000

24

29

17

19

8.0

9.0

20

22

29

1,050,000

27

33

17

19

8.0

9.0

20

25

33

Nominal

air tube

length

---------

14” B

14” C

14” D

UTL

min.

---------

1 ¾”

0”

0”

UTL

max.

---------

9”

7 ½”

7 ½”

1,100,000

30

36

17

19

8.0

9.0

20

28

36

1,150,000

31

38

17

19

8.0

9.0

20

29

38

1,200,000

31

38

17

19

8.0

9.0

20

29

38

1,250,000

33

40

17

19

8.0

9.0

20

31

40

1,300,000

35

42

17

19

8.0

9.0

20

33

42

1,350,000

35

42

17

19

8.0

9.0

20

33

42

1,400,000

38

46

18

20

8.5

9.5

21

36

46

1,500,000

42

50

18

20

8.5

9.5

21

40

50

Note 1

Some tested appliances may operate satisfactorily with dimensions less than the above.

Note 2

Horizontal cylindrical chambers — diameter must be no less than column “W” above

Horizontal stainless steel cylindrical chambers — diameter at least 1 to 4 inches larger than column “W” above.

VC is the minimum diameter for vertical cylindrical chambers (refractory or refractory-lined chambers only).

Note 3

A corbel may help heat transfer in a larger boiler or furnace, provided it is recommended by the appliance manufacturer.

1. Prepare site • prepare burner • mount burner

(continued)