On 3.6 – Carbolite CAF DIGITAL IMAGING User Manual

Page 11

CAF Digital Imaging

MF36-3.21

page 11

the operator. Unless a supply cable is fitted the supply connections are to be made to terminals

mounted inside back of the furnace, accessed by removing the furnace back panel.

The terminals are marked according to the power supply, connect as shown in table 2. The

supply must incorporate an earth (ground).

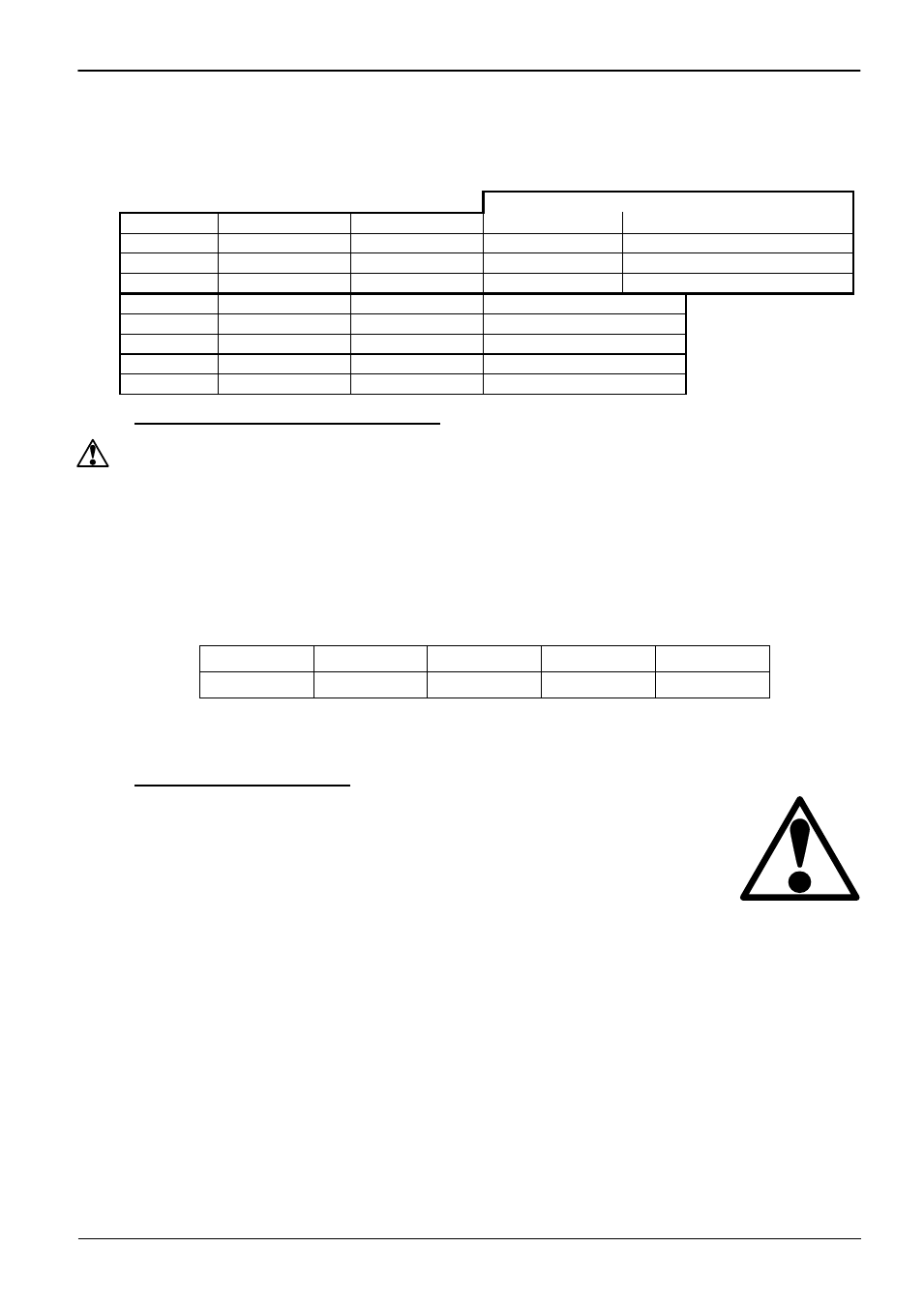

Table 2. Electrical connections:

Supply type

Supply

Terminal label

Cable colour

Live-Neutral

Reversible or Live-Live

1-phase

L or L1

Brown or Black

to live

to either power conductor

N or L2

Blue or Black

to neutral

to the other power conductor

PE

Green/Yellow

to earth (ground)

to earth (ground)

Supply

Terminal label

Cable colour

2-phase

L1

Black

to phase 1

L2

Black

to phase 2

N

Light Blue

to neutral

PE

Green/Yellow

to earth (ground)

3.6.

Voltage Level & Power Limit Settings.

Check the furnace rating label voltage. If the actual supply is not the same as the voltage on the

label, then the controller power limit should be adjusted as follows.

If the actual supply voltage is higher than the voltage on the rating label (or the voltage for

which the furnace was last set), then immediately after switch-on set the temperature setpoint to

zero to prevent heating and drawing excessive current.

Press Page until

oP

(output list) is displayed. Press Scroll until

OP.Hi

(Output High) is

displayed. Press Down or Up once to display the value of

OP.Hi

(it is good practice to

write down the original value). To alter the parameter use Down or Up .

Correct values for the

OP.Hi

parameter, with new elements, are:

200V

208V

220V/380V

230V/400V

240V/415V

79%

74%

65%

60%

55%

See also the section on element ageing – section 5.2.

3.7.

Exhaust Vent Connections.

Note: Significant amounts of carbon monoxide may be exhausted from the

work tube during the use of this furnace. Carbon monoxide is toxic and

inflammable (see section 1.2: Carbon Monoxide Warning.) it is

recommended that the vent tube is routed out of the building. The furnace

must always be positioned as recommended in section 3.4: Positioning The

Furnace.

The furnace has two exhaust vents, the main vent at the back of the heating

chamber and a safety pressure relief vent at the side of the furnace. The purpose of the safety

vent is to prevent dangerous pressure build up as the furnace warms up if the main vent tube

becomes blocked.

The main vent and the safety pressure relief vent must be connected to separate vent runs and

routed out of the building.

With the back panel removed access is gained to the main vent tube fitting situated on the work

tube back seal assembly below the thermocouples. The main vent tube fitting is a 12mm x 3/8”

BSP adapter suitable for connecting 12mm diameter copper tube. See fig 6.

The safety pressure relief vent tube fitting is a 6mm x 1/8” BSP adapter suitable for connecting

6mm copper tube. See fig 11.