Install base, Install leveling kit – B&W Trailer Hitches RVK3300 User Manual

Page 3

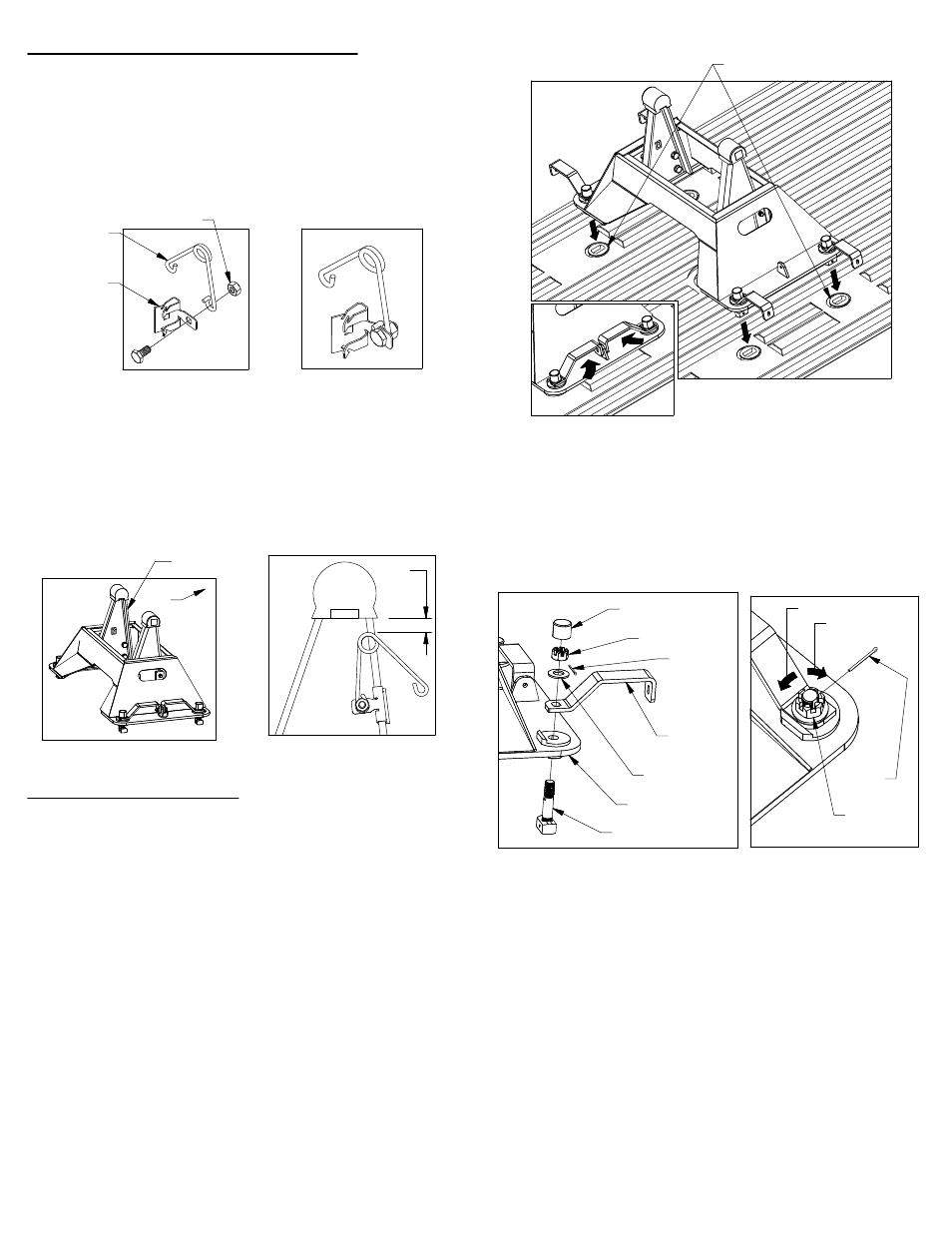

INSTALL BASE

The companion base will mount to four attachment

points in the truck bed. Remove any debris and/or

obstructions from the truck bed, this includes any

plastic caps which may be over the attachment points.

Remove the latch pins from each side of the base and

rotate the handles out, see figure C1. Place the

Companion base over the attachment points and

carefully lower it until the latch cams pass through the

floor and the base rests flat against the top of the

attachment points.

1.

Adjust the tension in the latch handle,

for parts list

and visual guide refer to figures C3 and C4.

Remove the plastic cap covering the castle nut. Next,

with a pair of needle nose pliers, un−bend and remove

the cotter pin installed at the top of the latch cam.

Next adjust the height of the castle nut.

3.

With the base firmly held down and each latch handle

closed, replace the latch pins removed in step one.

4.

Trial and error will have to be used to find the correct

latch tension for each attachment point. After the

tension is set, replace the cotter pin and re−bend the

ends. You may have to rotate the castle nut slightly to

allow the cotter pin to pass through. Replace the

plastic cap.

To tighten the latch handle (handle rotates without

any resistance) rotate the castle nut clockwise

(tighten) with a 15/16" wrench or socket.

To loosen the latch handle (handle is difficult to

rotate or cannot be closed) rotate the castle nut

counter−clockwise (loosen) with a 15/16" wrench or

socket.

INSTALL LEVELING KIT

Locate the 1/4" cap screw and nut, along with the wire

tension spring and mounting clip. Pass the 1/4" cap

screw through the mounting clip and the wire spring

as shown in figure B1. Thread the 1/4" lock nut onto

the 1/4" cap screw. Tighten the lock nut just enough

that the spring will stay in place but will still be able to

rotate around the bolt if needed, see figure B2.

1.

Locate the flange which will be closest to the truck cab

on the driver side pivot arm, see figure B3. The clip

should be placed so that when the springs coil is in the

line with the edge of the arm there will be 1/2" of

clearance between the bottom of the rubber bumper

and the top of the spring, see figure B4. Drive the clip

securely onto the flange with a hammer.

2.

Once the base is in place, turn each of the latch

handles as shown in figure C2. It is critical that the

base be drawn firmly down onto the attachment points.

You should feel some resistance while turning the

handles as the base is drawn down. If any of the

handles will not close or if they rotate freely with no

resistance, the tension on the latch handles will need

to be adjusted.

2.

FIGURE B4: Driver

side pivot arm.

FIGURE B1:

Leveling kit parts.

FIGURE B2:

Assembled leveling kit.

FIGURE C4: View of base leg.

FIGURE C1:

View of unlatched base

FIGURE C2:

View of closed latch handle

FIGURE C3: List of latch parts.

FIGURE B3: View of base.

COTTER

PIN

PLASTIC

CAP

CASTLE

NUT

SPRING

WASHER

LATCH

HANDLE

BASE LEG

LATCH CAM

LOOSEN

TIGHTEN

COTTER

PIN

CASTLE

NUT

1/2"

CAB

DRIVER SIDE

PIVOT ARM

MOUNTING

CLIP

WIRE

SPRING

1/4" LOCK NUT

ATTACHMENT POINTS