B&W Trailer Hitches Turnoverball Model 1257 (Toyota) User Manual

Before installing, Installation instructions, Ball location

An overhead-lifting device, such as chain falls, engine hoist, or cable come-

a-long, can be used to lift the center section of the hitch in place. Lower a

loop of rope or chain through the 4” hole in the truck bed floor and attach it

to the latch pin in the round hitch receiver tube in the center section. Use

the lifting device to raise the center section until the round hitch receiver

tube that protrudes from the center section fits in the 4” hole in the truck

bed floor. Maintaining upward pressure may facilitate fastening the cross-

member to the center section, especially if the truck bed floor has been

distorted downward from heavy use. If you use an overhead-lifting device, it should be disconnected before

squaring the center section across the frame, installing the sideplates and torquing fasteners.

INSTALLATION INSTRUCTIONS

BALL LOCATION:

2007 Toyota Tundra 4” hole location 42

3

/

8

” All beds.

Important Information

Because of space restraints the 2007 Toyota Tundra mounting kit contains components that have

not been seen in any previous Turnoverball™ kits. For this reason it will not be possible to

store the ball in the inverted position. It also makes the 4” hole location very critical. It

is important to read the complete instruction sheet before beginning the installation.

STEP 1 – MARKING AND CUTTING 4 INCH HOLE IN TRUCK BED

Begin by measuring for the correct hole location in the truck bed floor. Measure from the tail gate end of

the truck bed floor by hooking a tape measure over the end of the truck box and mark the floor at 42

3

/

8

”.

Next find the center point between the wheel wells, where these marks intersect with the first measurement

will be the center point of your four inch hole. This location is critical to the correct installation of the B&W

Turnoverball™ hitch so measure, mark and saw carefully. Make a four-inch hole at this location. B&W recom-

mends using a four-inch hole saw, however the hole can be cut by other means. If your truck has a spray-

in bed liner you will need to take into account when you are measuring to add the thickness of the applied

liner that has been sprayed over the end of the bed. If your truck has a drop-in plastic bed liner, you may

saw through both, but it is more difficult to accurately locate the midpoint between the fender wheel wells,

and to be sure that the bed liner does not move when sawing the hole. Once you have the four-inch hole in

the bed use a deburring tool or a die grinder and carefully remove the burr from the underside of the bed

around the hole.

WARNING

Most trucks have FUEL LINES and/or BRAKE LINES and/or ELECTRICAL WIRES located along the frame rails

where B&W Turnoverball™ hitches install. Carefully examine the location of fuel lines, brake lines and elec-

trical wires BEFORE INSTALLATION. Be certain you will not damage fuel lines, brake lines or electrical wires

when positioning hitch components, drilling holes, tightening fasteners, and lifting and lowering the truck bed.

The fuel tank vent, located on top of the gas tank, can be easily damaged during the installation of the hitch

components. Care must be taken when positioning the front crossmember and center section components.

WARNING

On Short bed trucks, BEFORE INSTALLING THIS HITCH, check for adequate turning clearance between the

front of all of your trailers and the truck cab.

NOTICE:

At this time no accessories, including the model RVK3000 RV Companion 5th wheel hitch, will work with this model

of turnoverball™ except:

• 4” Toyota Hitch Extender (part# 4585)

• RV Companion 5th wheel hitch (model RVK3500),

with special socket post.

BEFORE INSTALLING-

OVERHEAD LIFTING DEVICE

STEP 3 – Cross Member Installation

There are four crossmember parts included in the kit. Two channel type and two flat type. Place one of the

channel crossmembers between the top of the frame and the under side of the bed. Make sure that both

flanges of the channel are facing down and the notches at each end are toward the front of the truck. Once

the crossmember is across both frame rails rotate it down and slide forward. Next install a flat crossmem-

ber in the same manner and slide it forward. Install the other two in the same manner except with the

notches facing the rear of the truck. Slide them toward the rear as far as possible.

STEP 4 – Center Section Installation

Install 1/2” x 2” carriage bolts through the center four holes of the front crossmembers. The threaded

part of the bolts should face toward the rear of the truck with the square part of the bolts fitting into the

square holes in the crossmembers. With the latch pin on the driver’s side, lift the center section up on to

the bolts and hand tighten with flat washers, lock washers, and nuts. Now the center section and the front

crossmember can slide forward. This will allow the 4” round top of the center to be placed into the hole in

the truck bed. A lifting device as describe previously will help if available. With the top of the center section

placed through the hole in the bed, slide the rear crossmembers against the rear of the center and install

carriage bolts in the same manner as before. All bolts must be left loose at this point for sideplate instal-

lation.

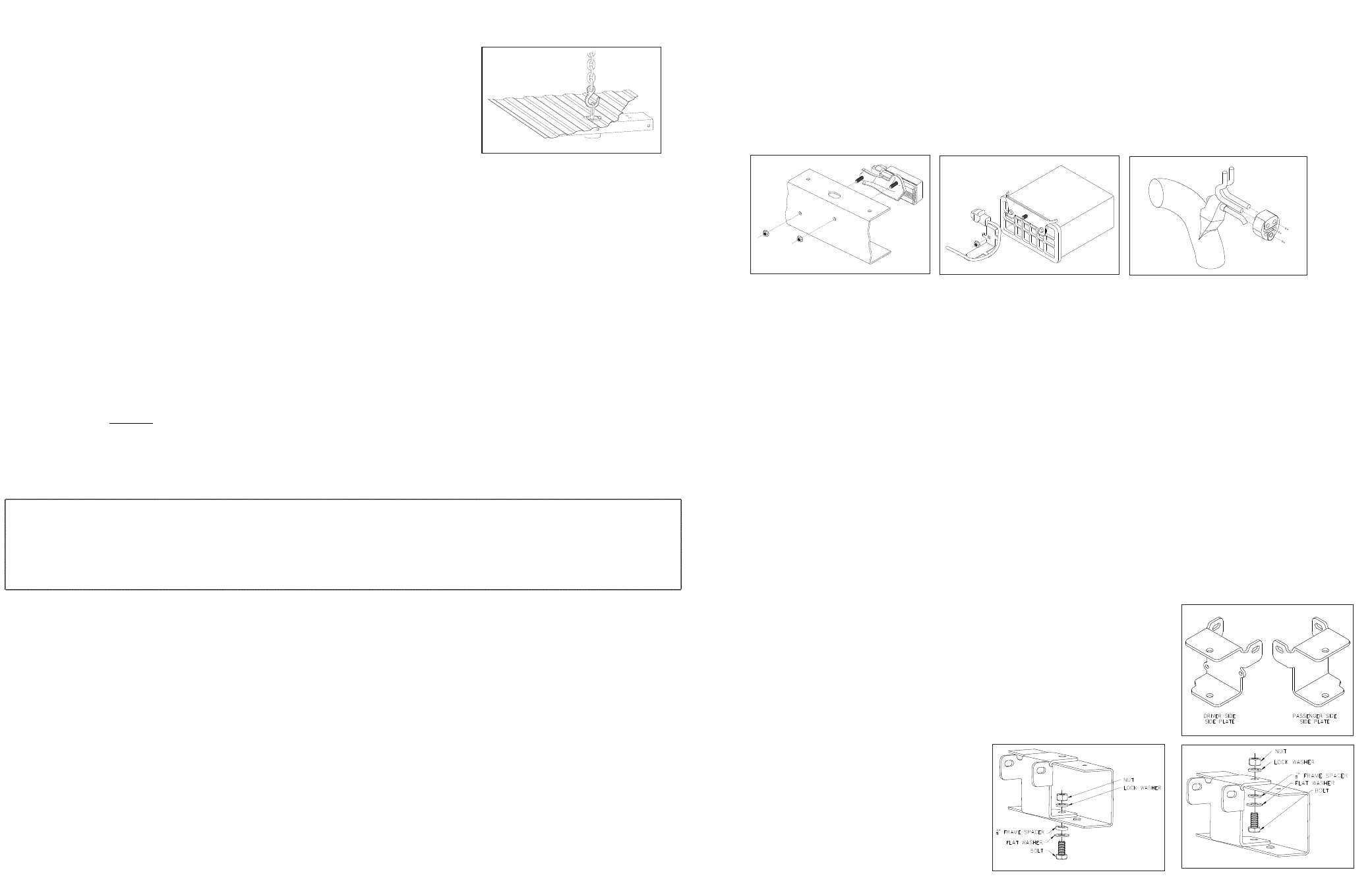

STEP 5 – Side Plate Installation

Using the diagram at the right determine the driver and passenger side-

plates. Place the appropriate side plate on the inside of the frame with the

small flanges fitting between the crossmembers. The top long flange will

sit on the upper leg of the frame with the bottom long flange sitting on

the top of lower leg of the frame. With each sideplate in place insert car-

riage bolts through the square holes in the crossmembers and through the

small flanges on the sideplates. Place a flat washer, lock washer and nut

on the bolts and leave loose at this time.

Next place a 5/8” x 1-1/2” bolt with a flat

washer and frame spacer (see diagram at

right) through the oval holes in the frame.

Two will go through the bottom frame leg

using a 1/4” frame spacer and two in the

top frame leg using a 1/8” frame spacer. Af-

ter passing through the frame and sideplate

install a lock washer and nut.

STEP 2 – Pre-Installation

Remove the two bolts holding the exhaust heat shield using a 10 mm wrench. Locate the fuel pump control

on the inside of the driver’s side frame. Using a 12 mm wrench remove the two nuts on the outside of the

frame that are holding it in place (Fig. 1). Retain the nuts to be replaced later. Next locate the fuel vapor

canister box mounted just under the front bed crossmember on the driver’s side of the truck. Remove the

nut holding the wiring bracket to the back of the box (Fig. 2). This will be relocated later. On the top of the

passenger side frame rail locate the plastic wiring bracket and remove from top of frame. Place the wiring

harness inside the frame rail. It will be held in place with the sideplate. Locate the tail pipe hanger toward

the back of the tail pipe and slide the rubber hanger off of the tubing that is welded to the pipe (Fig. 3).

(Fig. 1)

(Fig. 2)

(Fig. 3)