Installation instructions, Ball location – B&W Trailer Hitches 1111 User Manual

Page 2

INSTALLATION INSTRUCTIONS

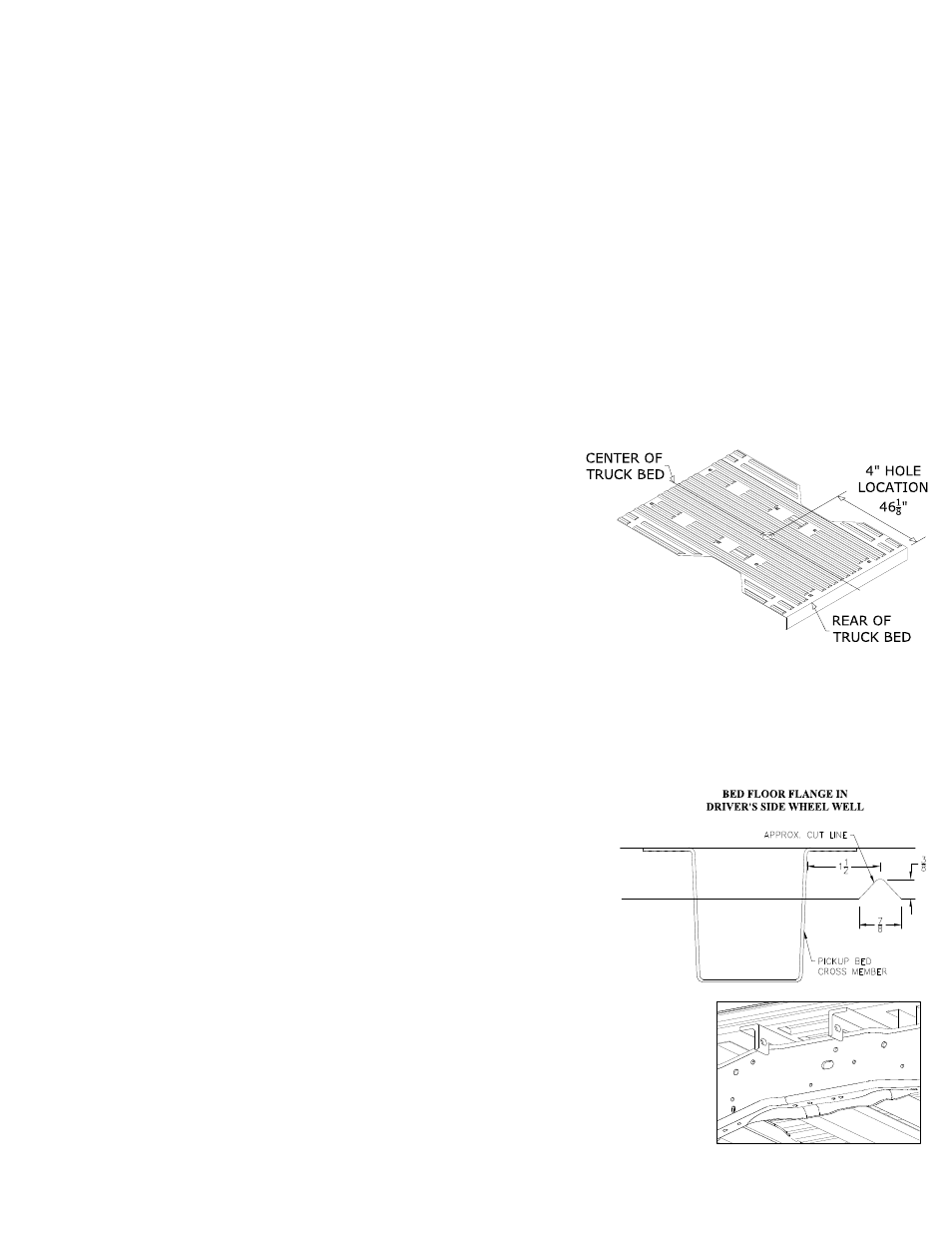

BALL LOCATION:

F250 AND F350 SHORT AND LONG BED SUPER DUTY’S &

F450 with Factory Installed Bed = 46-1/8”

STEP 1 – MARKING AND CUTTING 4-INCH-HOLE IN TRUCK BED

Begin by measuring for the correct hole location in the truck bed floor. Measure

from the tail gate end of the truck bed floor by hooking a tape measure over the

end of the truck box and mark the floor at 46-1/8”. Next find the center point

between the wheel wells, where these marks intersect with the first measure-

ment will be the center point of your four inch hole. This location is critical to

the correct installation of the B&W Turnoverball™, so measure, mark and saw

carefully. Make a four-inch hole at this location. B&W recommends using a four

inch hole saw, however the hole can be cut by other means. If your truck has a

spray-in bed liner, you will need to take into account when you are measuring to

add the thickness of the applied liner that has been sprayed over the end of the

bed. If your truck has a Drop-in plastic bed liner, you may saw through both, but

it is more difficult to accurately locate the midpoint between the fender wheel

wells. Be sure that the bed liner does not move when sawing the hole. Once you

have the four-inch hole in the bed, use a de-burring tool or a die grinder and

carefully remove the burr from the under side of the bed around the hole.

STEP 2 – HEAT SHIELD REMOVAL

Remove the heat shield located above the rear axle under the truck bed.

STEP 4 – BED FLANGE MODIFICATION

Some models of trucks will allow the crossmembers to slide between the frame and

bed without modification. If this is not possible a small notch needs to be made in the

flange on the driver’s side of the truck. (see diagram)

Locate the front truck bed cross member in the wheel well. Measure from the back of

the cross member and make a mark at 1 ½”. This will be the center point for the notch

that is needed. Mark and cut a 7/8” wide by 3/8” tall notch.

STEP 5 – CROSS MEMBER INSTALLATION

The 1111 mounting kit is supplied with two angle crossmembers. The rear crossmember has three

notches and will be installed first. Slide the rear crossmember between the frame and bed on the

driver’s side. If necessary use the notch cut into the bed flange in step 4. Make certain the leg of

the angle with the oval holes is facing toward the cab. After sliding the angle in about half way it

may need to be guided onto the other frame from the underside the truck. At this point the angle

should span between both frame rails and in front of the shock bracket on the passenger side. Next

using the notch over the shock bracket for clearance, roll the angle iron over the bracket while slid-

ing it toward the rear. It is important to hold the driver’s side of the crossmember upward

against the bed floor and forward against the bed crossmember. Continue to slide it back

until it is about four inches behind the four inch hole that has been drilled in the bed. Next install

the front angle in the same manor except for the leg of the angle with the oval holes should face the

rear of the truck during installation. Slide it rearward just behind the shock bracket and leave until

needed for installation. When installed correctly the two angle legs with the holes should be facing

each other. (see figure 5.1.)

WARNING

Most trucks have FUEL LINES and/or BRAKE LINES and/or ELECTRICAL WIRES located along the frame rails where B&W Turnoverball™

hitches install. Carefully examine the location of fuel lines, brake lines and electrical wires BEFORE INSTALLATION. Be certain you

will not damage fuel lines, brake lines or electrical wires when positioning hitch components, drilling holes, tightening fasteners, and

lifting and lowering the truck bed. The fuel tank vent, located on top of the gas tank, can be easily damaged during the installation

of the hitch components. Care must be taken when positioning the front crossmember and center section components.

WARNING

On Short bed trucks, BEFORE INSTALLING THIS HITCH, check for adequate turning clearance between the front of all of your trailers

and the truck cab.

WARNING

DO NOT invert the ball in the socket when carrying heavy loads on 2 wheel drive trucks. The ball may hit the top of the differential.

Remove the ball from the socket before loading. A plug for the socket is available from B&W.

STEP 3 – EXHAUST BRACKET REMOVAL

On trucks equipped with a diesel engine the tail pipe will need to be lowered. Un-attach the tail pipe bracket just behind the rear tire

on the passenger side. Installation on gasoline equipped trucks may be easier if exhaust is detached. The bracket will be reattached

later.

****SAFETY NOTICE*****

if a spare tire heat shield is present, we recommend that it be removed to avoid injury.

REMOVE SPARE TIRE BEFORE INSTALLING HITCH.

figure 5.1, outside of driver

side frame