Ammco drum & disc brake lathes • 7 – AMMCO 4000E Drum and Disc Brake lathe User Manual

Page 9

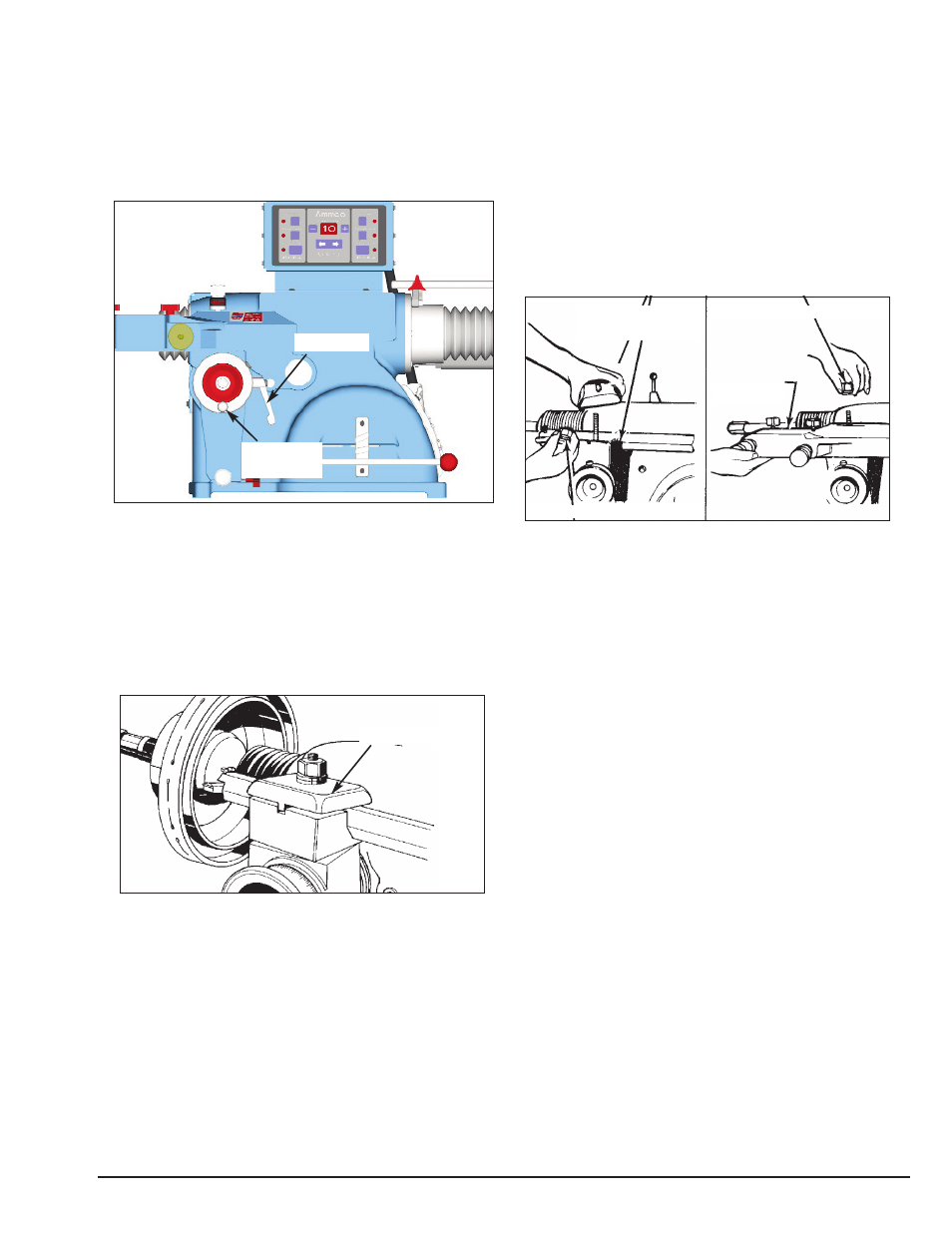

Cross Feed Handwheel & Feed Lever

Clockwise rotation of the cross feed handwheel

moves the cutting tool in towards the lathe.

Counterclockwise rotation of the cross feed hand-

wheel moves the cutting tool away from the lathe.

Engaging the feed lever completes the feed cycle.

Figure 1 – Rotation of handwheels & Feed Lever

Boring Bar

A boring bar is used to recondition a brake drum.

Clean the slide and bottom of the boring bar clamp.

Install the boring bar and boring bar clamp onto slide,

over the stud bolt and secure with self-aligning nut.

Handtighten the nut only at this point. Make sure the

tool bit is clean and sharp. Replace as necessary to

ensure smooth reconditioning.

Figure 2 - Boring Bar

Twin Cutter

A twin cutter tool is used on to recondition both sur-

faces of a brake rotor at the same time. The twin cutter

replaces the boring bar on top of the cross feed after

removing the upper and lower tool bar clamps.

1. Mount the twin cutter on the cross feed with the

stud bolt extending through the cast slot. The slot helps

center the twin cutter to the rotor.

2. Secure the twin cutter to the cross feed with self-

aligning nut and washer assembly. Tighten the nut

firmly.

Figure 3 – Install the Twin Cutte

r

AMMCO Drum & Disc Brake Lathes • 7

Cross Feed

Handwheel

Feed Lever

Spindle rotates when

motor is turned on.

Upper and lower

boring bar clamps

Cross slide self-aligning nut/washer

Twin cutter

Cross slide self-aligning nut/washer

Boring Bar Clamp