14 • ammco drum & disc brake lathes – AMMCO 4000E Drum and Disc Brake lathe User Manual

Page 16

14 • AMMCO Drum & Disc Brake Lathes

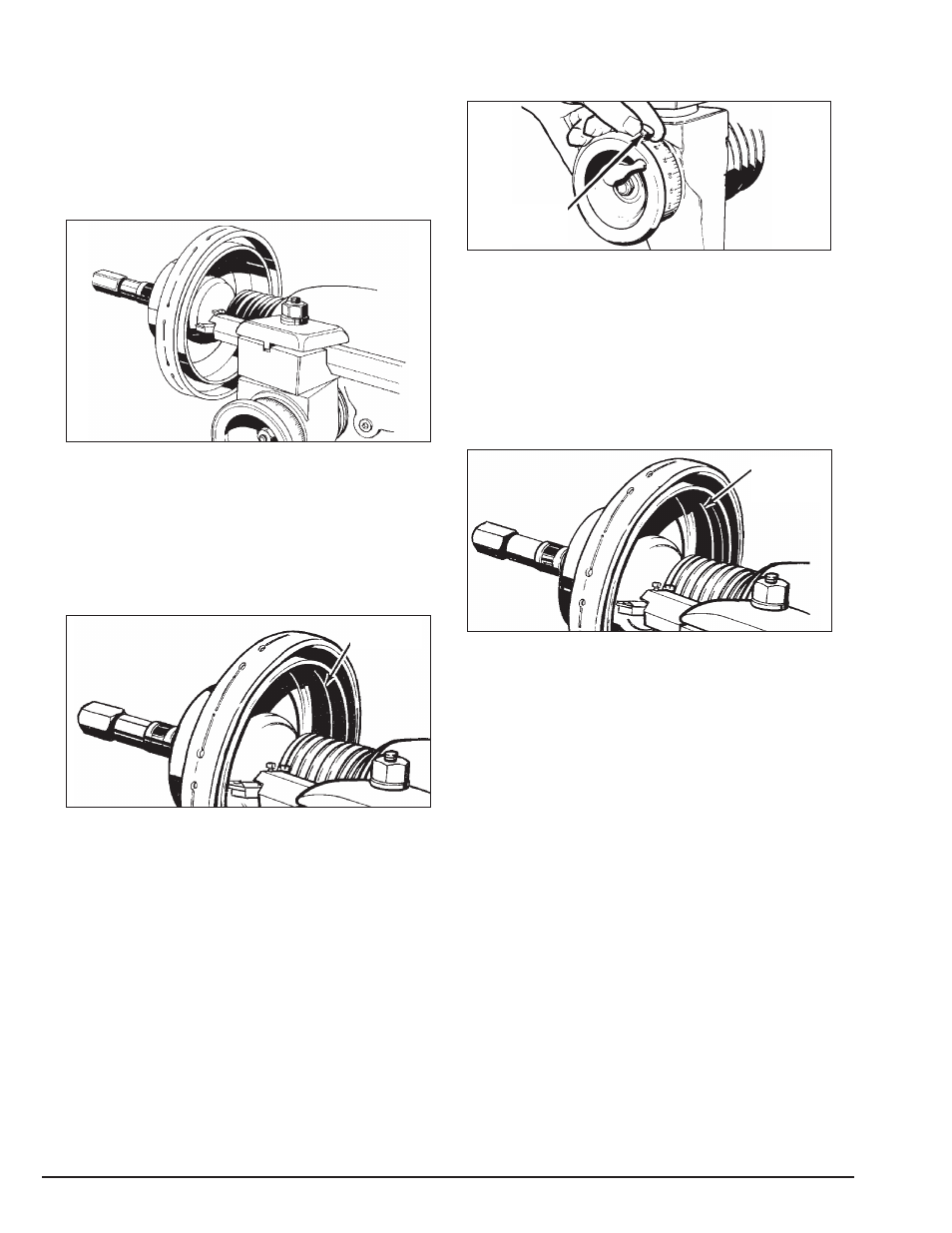

5. Position the boring bar by loosening the boring bar

clamp nut and sliding the boring bar inward toward the

drum until the tool bit is close to the drum.

The boring bar position is changed whenever a drum

of different diameter is machined.

The entire boring bar clamp may also be swiveled to

achieve the best cutting position.

Figure 19 – Positioning the boring bar

6. Turn the drum by hand to make sure that every-

thing is clear.

7. Turn the lathe ON.

8. Advance the tool bit using the cross feed hand-

wheel until it just contacts the drum surface momen-

tarily and makes a scratch cut.

Figure 20 – First scratch cut

9. Loosen the dial lock screw on the cross feed hand-

wheel and set the dial to the diameter of the drum as

measured with the micrometer. Tighten the lock screw.

This setting will be the reference used to help deter-

mine the drum recondition diameter.

Figure 21 – Set drum diameter measurement

10. Back the tool bit off and turn the lathe OFF.

11. Loosen the arbor nut, rotate the drum 1⁄2 turn

(180°) on the arbor and inner adapter, and retighten the

nut.

12. Turn the lathe ON.

13. Turn the workpiece on the spindle 1⁄2 turn in

either direction and make a second scratch cut.

Figure 22 – Second scratch cut

14. Turn the lathe OFF.

15. Examine the scratch cuts.

If the first and second cuts are opposite one another

(180° apart), remove the drum from the arbor, check the

mounting adapters and arbor for nicks, burrs, or chips,

remount the drum, and repeat scratch cut process.

If the scratches are side by side, proceed to step 16.

16. Turn the lathe on and use spindle jog button to

position the tool bit until the deepest worn groove of

the drum lines up with the point of the tool bit.

First

Scratch Cut

Dial Lock

Screw

Second

Scratch Cut