Reconditioning brake drums, Ammco drum & disc brake lathes • 13, Preparation – AMMCO 4000E Drum and Disc Brake lathe User Manual

Page 15: Mounting drums

AMMCO Drum & Disc Brake Lathes • 13

Reconditioning Brake

Drums

Preparation

1. Measure the diameter of the brake drum with a

brake drum micrometer.

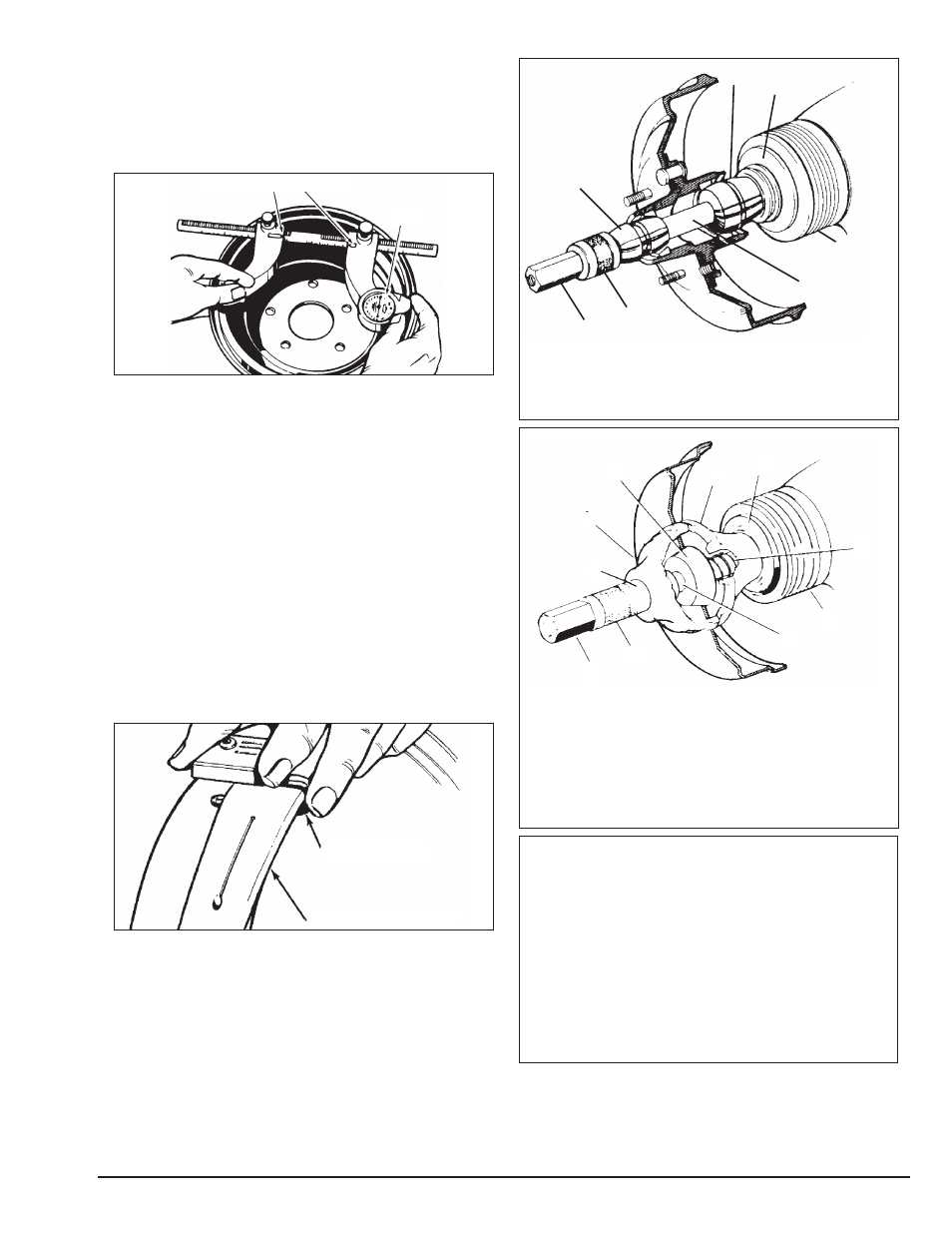

Figure 16 – Measure drum diameter

2. Determine if the drum will be within maximum

rebore limits after reconditioning.

Note: Most often, the DISCARD diameter is cast into

the brake drum, not the maximum machining diameter.

3. Inspect brake drum. Do not attempt to machine a

drum that is damaged or in poor condition.

Mounting Drums

1. Loosen the boring bar clamp nut and push the bor-

ing bar all the way into the clamp.

2. Mount the drum on the arbor using the proper

adapters, cones, and spacers. Use examples in Figure

18 for guidance.

3. Wrap the drum silencer band snugly around the

drum. Be sure it covers up to the right-hand edge.

Figure 17 – Attach silencer band

4. Position the cross slide by turning the cross feed

handwheel to its maximum clockwise (in) position. Then

back off the cross feed handwheel 2 complete turns .

Figure 18 - Mounting the Drum

Note: Also refer to the Double Chuck Adapter section

(page 10) when mounting drums or rotors using the

Ammco

®

double chuck.

Hubbed Brake Drums

A

C

B

L

K

D

F

Tapered cone adapters fit in the bearing seats, making con-

tact near the middle of the bearing race whenever possible

rather than near an edge. Various adapters and spacers may

be used to fill out the shaft of the arbor.

Hubless Brake Drums

A

C

B

E

H

D

F

A cone fits into the center hole of the drum from the inside

to center the drum on the arbor. Select a hubless adapter

which will fit inside the drum, against the flat lug hole sur-

face and either straddle the bolt holes to avoid mounting

against a burr, or remove the burrs. Slip the hubless

adapter onto the arbor followed by a spring, the cone, the

drum, and another hubless adapter. Fill out the shaft with

spacers as needed.

J

I

G

Key to Mounting Adapters, Cones, and Related Parts

A. 1” Arbor

G. Spring

B. Arbor Nut

H. Inside Floating Adapter (sm.)

C. Self-Aligning Spacer

I.

Outside Floating Adapter (lg.)

D. Lathe Spindle Nose

J. Centering Cone

E. Spacer

K. Large Double Taper Adapter

F.

Protective Boot

L. Small Double Taper Adapter

Note: The self-aligning spacer should always be used next

to the arbor nut when tightening. To avoid overtightening,

wrench tighten the arbor nut counterclockwise until the

drum and adapters begin to turn on the arbor, then continue

to advance the wrench

1

⁄

16

of a turn. DO NOT overtighten

the arbor nut.

Arrows for reading scale

Dial

Buckle Finger

Silencer Band for Drums