Caution – AMMCO 4000E Drum and Disc Brake lathe User Manual

Page 12

10 • AMMCO Drum & Disc Brake Lathes

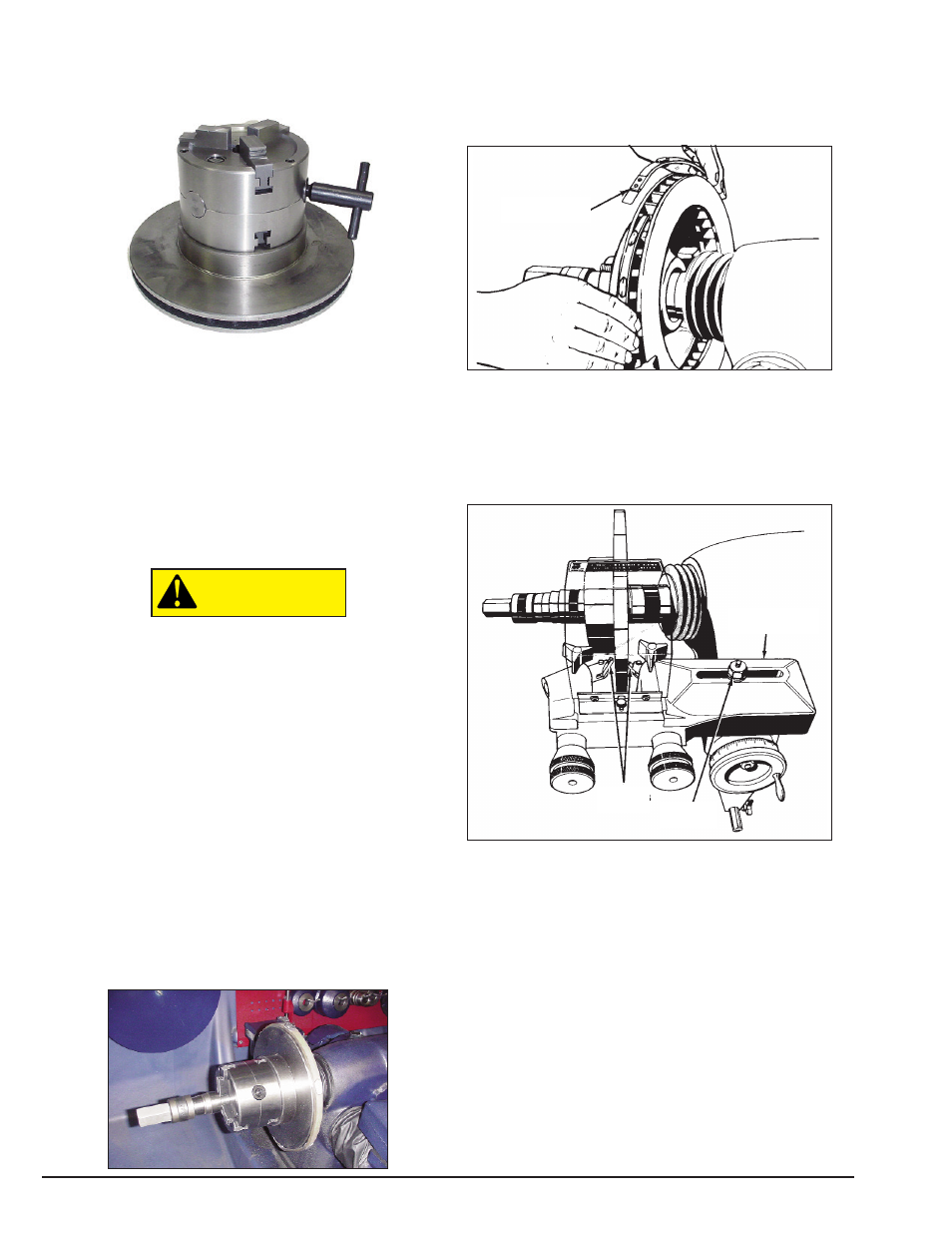

Double Chuck Adapter

Mounting drums or rotors using the Ammco double

chuck adapter.

Figure 6 – Double Chuck Adapter

1. Thoroughly clean the surface of the rotor or drum

that will be mounted on the double chuck.

2. Place the hubless rotor or drum on a flat clean sur-

face. Install the double chuck by positioning the appro-

priate jaws in the center hole. Tighten the jaws by

inserting the key into one of the key slots in the side of

the chuck turning counterclockwise. The double chuck

will automatically self center the rotor or drum.

Note: Make sure that the chuck jaws are tight.

Do not leave the key in the key slot when

starting the brake lathe.

3. Install the backing plate onto the brake lathe arbor

with offset facing outward.

4. Install the double chuck, with rotor or drum

installed, onto the 1-inch arbor. Use the spacers sup-

plied with the brake lathe so that it extends out to the

arbor threads.

5. Use the arbor nut supplied with the machine and

tighten the nut against the spacers.

6. After tightening the double chuck, turn on the

brake lathe to check for runout of the rotor or brake

drum. Machine the rotor or drum.

Note: Always use the backing plate to help eliminate

rotor or drum vibration during turning. If necessary, use

a small spacer before the installation of the backing

plate.

Set Up and Reconditioning Rotors

1. Install a silencer band on the mounted rotor.

Stretch the band around the rotor and hook the metal

loop over a lead weight.

Figure 7 – Attach Silencer Band

2. Center the twin cutter to the rotor. Loosen the

stud nut and adjust the twin cutter so that the rotor is

centered between the tool bits. The slot of the twin cut-

ter should be approximately parallel to the lathe spin-

dle. Tighten the stud nut firmly.

Figure 8 – Center the Twin Cutter

CAUTION

Silencer band

Twin cutter

Stud nut

Tool bits