Reconditioning disc brake rotors, 8 • ammco drum & disc brake lathes – AMMCO 4000E Drum and Disc Brake lathe User Manual

Page 10

Reconditioning Disc

Brake Rotors

Preparation

1. Inspect the rotor carefully for scoring, rust ridges

(at the inner and outer circumference of the rotor), and

hard spots. Any excessive wear or deformity should be

noted and, if not within acceptable limits, the rotor

should be replaced.

2. Use a micrometer to check the thickness of the

rotor at no less than 3 points around the circumference

about 1” (2.54 mm) in from the outer diameter.

If the rotor thickness varies between readings, it

should be reconditioned. However, if the thickness is

less than the minimum established by the manufac-

turer, or if it will be less after reconditioning, the rotor

should be replaced.

Note: Most often

the DISCARD thick-

ness dimension is

cast or stamped into

the rotor, not the

minimum machine-

to thickness.

Figure 4 – Measure Rotor Thickness

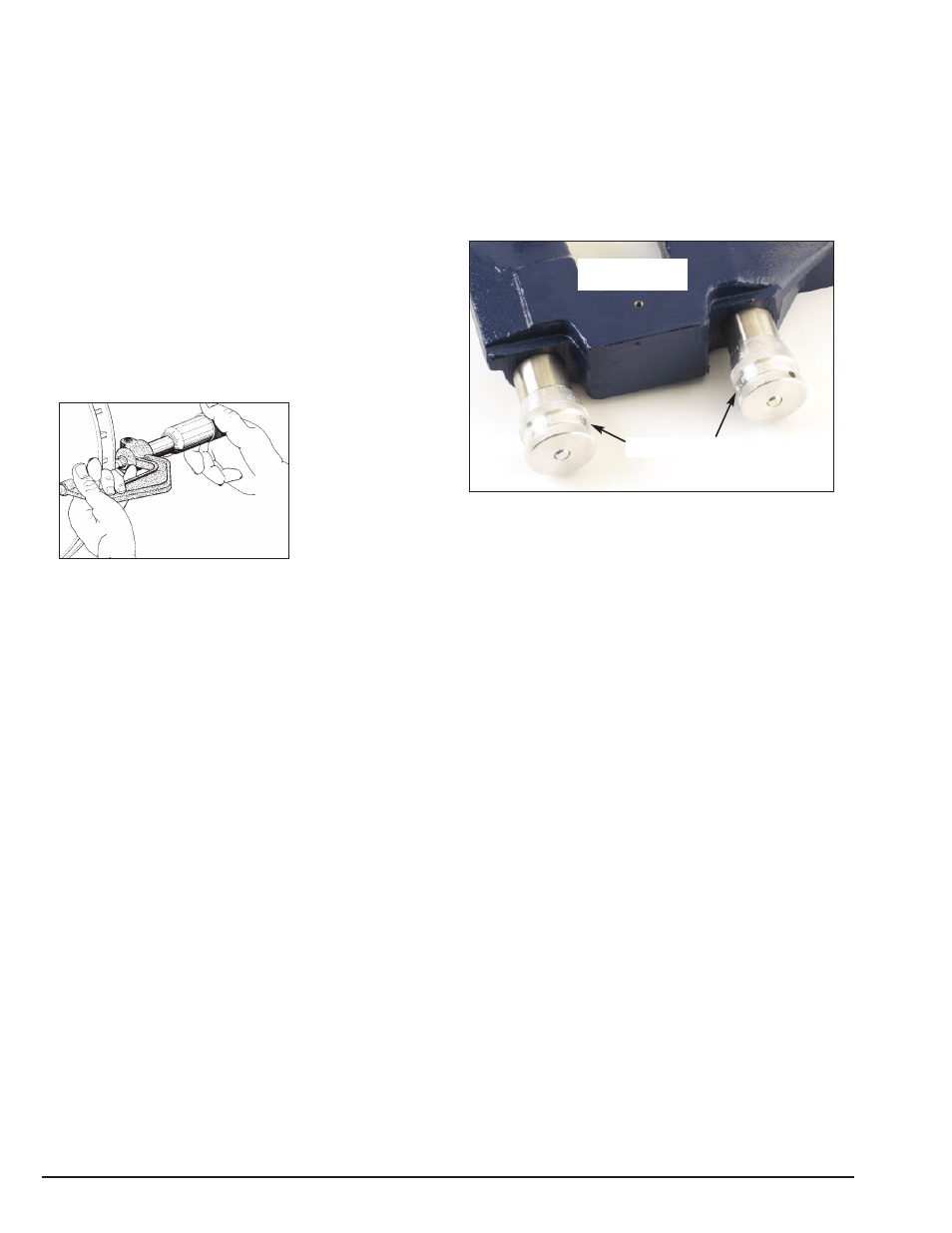

Model 6950 Twin Cutter

The 6950 twin cutter mounts on the cross feed tool

post to resurface both rotor surfaces simultaneously.

Each tool bar is individually adjustable (in thousandths

of an inch or millimeters) to permit precise depth-of-cut

settings.

The tool bars mount on top of the tool bar support,

carbide tips up, and are used to recondition both brake

surfaces of a rotor at the same time.

Figure 5 – 6950 Twin Cutter Controls

Installation

1. Remove the self-aligning nut/washer assembly

retaining the boring bar clamp.

2. Remove the clamp and boring bar.

Note: Older lathes have a tool post pivot screw which

must be loosened before the lower clamp can be

removed.

3. Place the tool bar support over the cross feed tool

post stud and replace self-aligning nut/washer assem-

bly.

4. Align the tool bar support parallel with the arbor

and wrench tighten the nut.

Preparation

1. Inspect the rotor carefully for scoring, rust ridges

(at the inner and outer circumference of the rotor), and

hard spots. Any excessive wear or deformity should be

noted and, if not within acceptable limits, the rotor

should be replaced.

2. Use a micrometer to check the thickness of the

rotor at no less than 3 points around the circumference

about 1” (2.54 mm) in from the outer diameter.

If the rotor thickness varies between readings, it

should be reconditioned. However, if the thickness is

less than the minimum established by the manufac-

turer, or if it will be less after reconditioning, the rotor

should be replaced.

Note: Most often the DISCARD thickness dimension

is cast or stamped into the rotor, not the minimum

machine-to thickness.

Inch/Millimeter

Micrometer Dials

Adjustment Knobs

8 • AMMCO Drum & Disc Brake Lathes