JLG 600SC_660SJC ANSI Service Manual User Manual

Page 29

SECTION 2 - GENERAL

3120794

– JLG Lift –

2-7

Swing Brakes

5

Boom Synchronization/Sequencing Systems

5

Manual Descent or Auxiliary Power

5

5

Power System

9

Engine Idle, Throttle, and RPM

3

3

Engine Fluids (Oil, Coolant, Fuel)

11

9,11

11

11

Air/Fuel Filter

1,7

7

7

Exhaust System

1,9

9

9

Batteries

5

1,9

19

Battery Fluid

11

11

11

Battery Charger

5

5

Fuel Reservoir, Cap, and Breather

11,9

2

1,5

1,5

Hydraulic/Electric System

9

Hydraulic Pumps

1,9

1,2,9

Hydraulic Cylinders

1,9,7

2

1,2,9

1,2,9

Cylinder Attachment Pins and Pin Retainers

1,9

1,2

1,2

Hydraulic Hoses, Lines, and Fittings

1,9

12

1,2,9,12

1,2,9,12

Hydraulic Reservoir, Cap, and Breather

11

1,9

2

1,5

1,5

24

Hydraulic Filter

1,9

7

7

Hydraulic Fluid

11

7,11

7,11

Electrical Connections

1

20

20

Instruments, Gauges, Switches, Lights, Horn

1

5,23

General

Operators and Safety Manuals in Storage Box

21

21

21

ANSI and EMI Manuals/Handbooks Installed

21

Capacity Decals Installed, Secure, Legible

21

21

21

All Decals/Placards Installed, Secure, Legible

21

21

21

Walk-Around Inspection Performed

21

Annual Machine Inspection Due

21

No Unauthorized Modifications or Additions

21

21

All Relevant Safety Publications Incorporated

21

21

General Structural Condition and Welds

2,4

2,4

All Fasteners, Pins, Shields, and Covers

1,2

1,2

Grease and Lubricate to Specifications

22

22

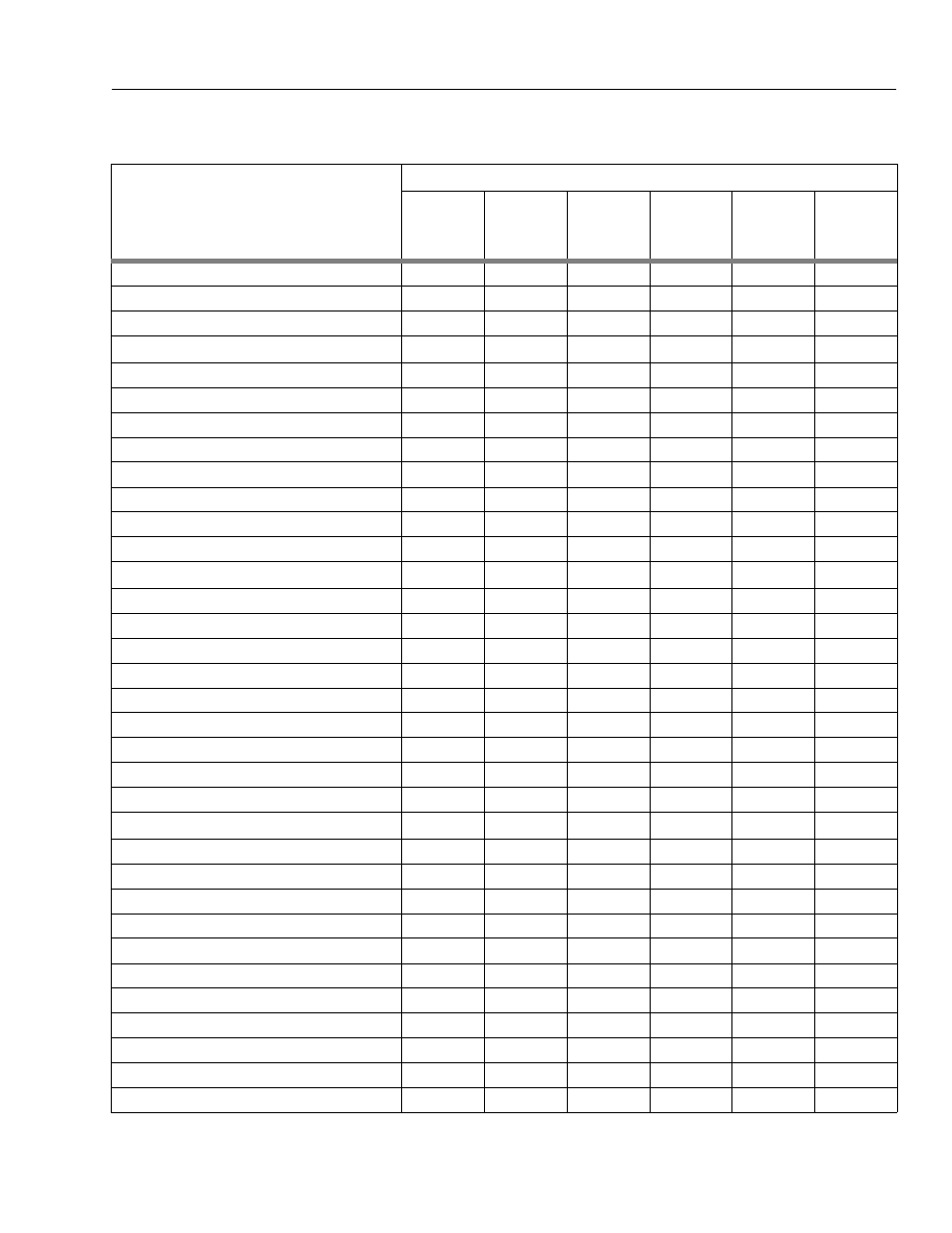

Table 2-3. Inspection and Preventive Maintenance Schedule

AREA

INTERVAL

Pre-Start

1

Inspection

Weekly

Preventive

Maintenance

Monthly

Preventive

Maintenance

Pre-Delivery

2

or Frequent

3

Inspection

Annual

4

(Yearly)

Inspection

Every 2

Years