Recoil spring disassembly, Recoil spring disassembly -22, Recoil spring assembly -22 – JLG 600SC_660SJC ANSI Service Manual User Manual

Page 126: Recoil spring required tools - disassembly -22

SECTION 6 - UNDERCARRIAGE

6-22

– JLG Lift –

3120794

11.

Install spring pin (1). The illustration above shows

the positioning of the slit in spring pin (1).

12.

Install the shaft and the bearing in the front idler.

13.

Repeat step 10 in order to install the bearing on the

opposite side of the shaft (4).

14.

Be sure that the spring pin hole in the shaft is

aligned with the spring pin hole in the bearing.

NOTE: Do not reuse spring pin (1). Use a new part for

replacement.

15.

Install spring pin (1).

16.

Check the front idler for air leaks. Apply 36 to 37 psi

(245 to 256 kPa) of air pressure to the idler for 30

seconds. If the pressure remains constant for 30

seconds, assume that there are no leaks in the front

idler.

17.

Put the front idler in a vertical position. Fill the front

idler with 5.07 oz. of clean SAE30 oil.

18.

Put a thin coat of thread lock compound on the

threads of the fill/drain plug. Install the fill/drain plug.

Recoil Spring Disassembly

PERSONAL INJURY OR DEATH CAN RESULT FROM RECOIL

SPRING FORCE.

RECOIL SPRING FORCE, IF NOT RELIEVED, CAN RESULT IN

PERSONAL INJURY OR DEATH.

RELIEVE SPRING FORCE BEFORE REMOVING THREADED

RETAINER, PERFORMING REPAIRS ON RECOIL SPRING HOUS-

ING, OR REMOVING RECOIL SPRING.

MAXIMUM RECOIL PRESSURE IS 3,000 PSI (20,700 KPA).

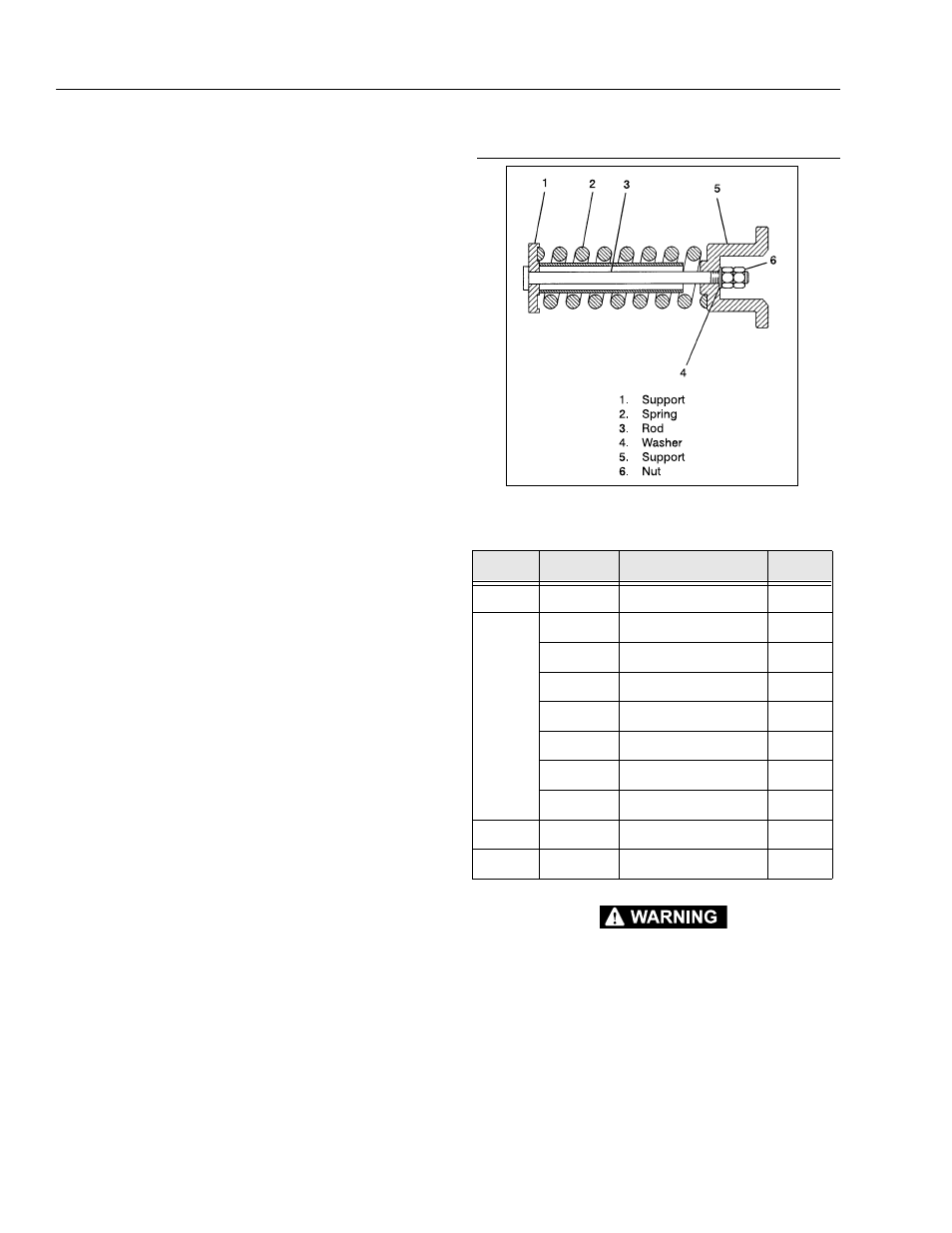

Table 6-9. Recoil Spring Required Tools - Disassembly

Tool

Part #

Description

Qty.

A

4C-9540

Bench

1

B

8S-7172

Hydraulic Cylinder

1

3S-6224

Electric Hydraulic Pump

1

8T-0820

Pressure Gauge

1

3B-7722

Bushing

2

1P-2376

Coupler Assembly

2

1P-2377

Plug

2

8F-0024

Hose Assembly

2

C

8S-9971

Ram Adapter

1

D

9U-6545

46mm Socket

1

Figure 6-9. Recoil Spring Assembly