Warning, Aerovent im-745 9 – Aerovent IM-745 User Manual

Page 9

Aerovent IM-745

9

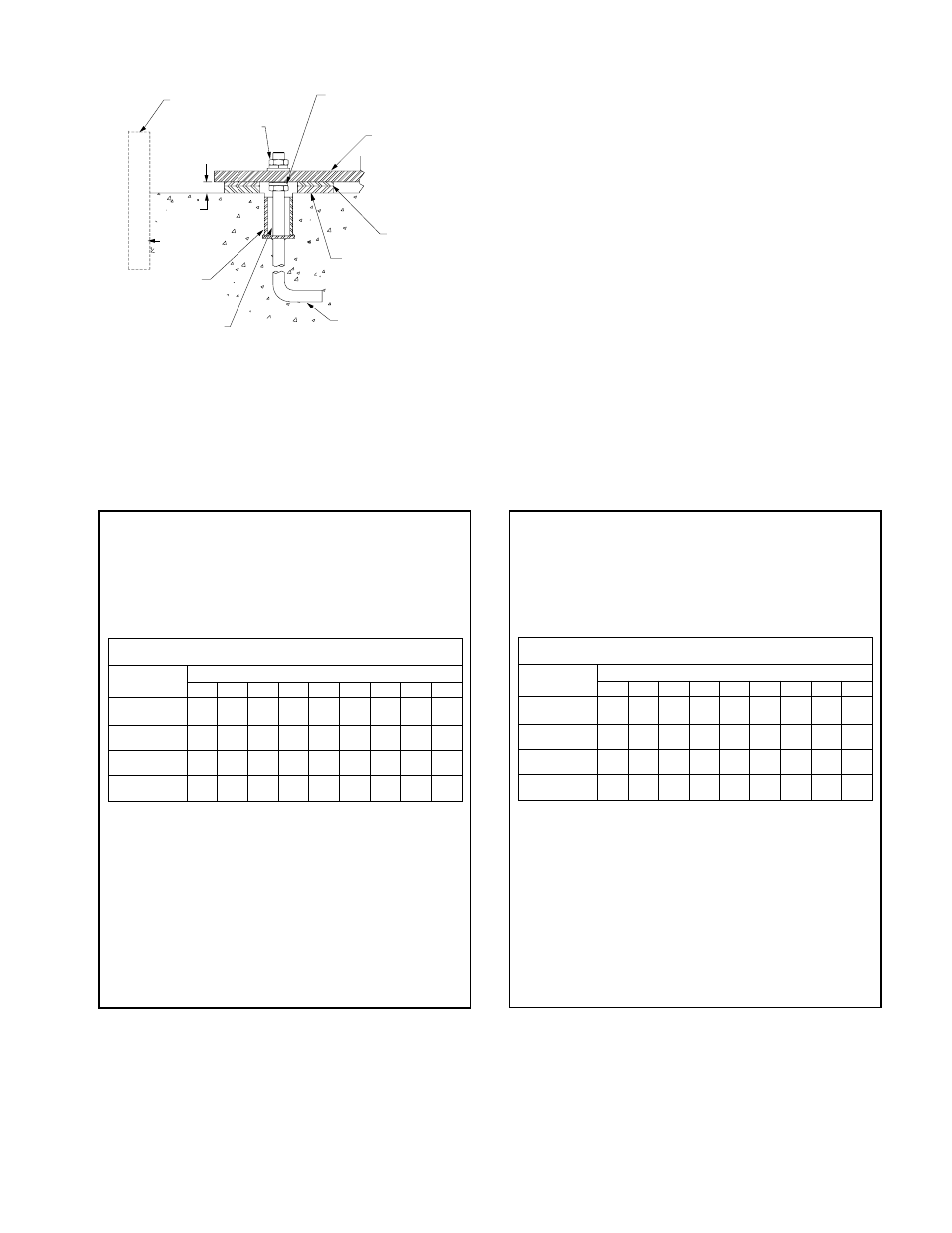

Temporary Form For

Grout Pouring

Hex Nut, Split Ring

Lock Washer, and

Tapered or Flat Washer

1" to 1.5"

Grout Allowance

To Be Filled With

Nonshrinking

Machinery Grout

Pipe-Bolt Sleeve

Dia. 2 to 2

1

/

2

Times

Bolt Dia. For Correction

of Alignment Errors

Care Should Be Taken

That Anchor Bolt Sleeves

Are Filled With Grout

J-Bolt Leg Should Be

Fastened To Foundation

Rebar

Full Width Stainless

Steel Shims

Shimming Surface To Be

Smooth, Level, Dressed

If Necessary

Leveling Nut, If Used, Should Be

Backed Off After Shimming For

Final Tightening of Hex Nuts

Fan Base Angle

or Structural Steel

Figure 8. Typical Foundation Section

WARNING

1. This equipment must not be operated without proper guarding of

all moving parts. While performing maintenance be sure remote

power switches are locked off. See installation manual for recom-

mended safety practices.

2. Before starting: Check all setscrews for tightness and rotate wheel

by hand to make sure it has not moved in transit.

* Suggested lubrication interval under ideal continuous operating con-

ditions. Relubricate while running, if safety permits, until some purging

occurs at seals. Adjust lubrication frequency depending on conditions

of purged grease. Use one-half of listed interval for vertical shaft appli-

cations or for 24 hour operation. Hours of operation, temperature, and

surrounding conditions will affect the relubrication frequency required.

1. Lubricate with a high quality NLGI No. 2 lithium-base grease hav-

ing rust inhibitors and antioxidant additives, and a minimum oil

viscosity of 500 SUS at 100°F (38°C). Some greases having these

properties are:

Shell - Gadus S2 V100 2

Exxon - Ronex MP

Mobil - Mobilith SHC100

Mobil - Mobilith SHC220

2. Lubricate bearings prior to extended shutdown or storage and

rotate shaft monthly to aid corrosion protection.

Figure 9. Safety & Lubrication Instructions for Fans with Ball

Bearings

Relubrication Schedule (Months)*

Ball Bearing Pillow Blocks

Speed (RPM)

Shaft DIA

500 1000 1500 2000 2500 3000 3500 4000 4500

1

⁄

2

" thru 1

11

⁄

16

"

6

6

5

3

3

2

2

2

1

(13 – 45)

1

15

⁄

16

" thru 2

7

⁄

16

"

6

5

4

2

2

1

1

1

1

(50 – 60)

2

11

⁄

16

" thru 2

15

⁄

16

"

5

4

3

2

1

1

1

(65 – 75)

3

7

⁄

16

" thru 3

15

⁄

16

"

4

3

2

1

1

(80 – 100)

WARNING

1. This equipment must not be operated without proper guarding of

all moving parts. While performing maintenance be sure remote

power switches are locked off. See installation manual for recom-

mended safety practices.

2. Before starting: Check all setscrews for tightness and rotate wheel

by hand to make sure it has not moved in transit.

*Suggested lubrication interval under ideal continuous operating condi-

tions. Relubricate while running, if safety permits, until some purging

occurs at seals. Adjust lubrication frequency depending on conditions

of purged grease. Use one-half of listed interval for vertical shaft appli-

cations or for 24 hour operation. Hours of operation, temperature, and

surrounding conditions will affect the relubrication frequency required.

1. Lubricate with a high quality NLGI No. 2 lithium-base grease hav-

ing rust inhibitors and antioxidant additives, and a minimum oil

viscosity of 500 SUS at 100°F (38°C). Some greases having these

properties are:

Shell - Gadus S2 V100 2

Exxon - Ronex MP

Mobil - Mobilith SHC100

Mobil - Mobilith SHC220

2. Lubricate bearings prior to extended shutdown or storage and

rotate shaft monthly to aid corrosion protection.

Relubrication Schedule (Months)*

Spherical Roller Bearing - Solid Pillow Blocks

Speed (RPM)

Shaft DIA

500 1000 1500 2000 2500 3000 3500 4000 4500

1" thru 1

7

⁄

16

"

6

4

4

2

1

1

1

1

1

⁄

2

(25 – 35)

1

11

⁄

16

" thru 2

3

⁄

16

"

4

2

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

1

⁄

2

(40 – 55)

2

7

⁄

16

" thru 3

7

⁄

16

"

3

1

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

4

1

⁄

4

(60 – 85)

3

15

⁄

16

" thru 4

15

⁄

16

"

2

1

⁄

2

1

1

⁄

2

1

⁄

4

(90 – 125)

Figure 10. Safety & Lubrication Instructions for Fans

with Unit Roller Bearings