Aerovent IM-745 User Manual

Page 8

8

Aerovent IM-745

Bearing Problems

Generally speaking, Aerovent uses three types of bearings:

1. Ball bearings with setscrew lock;

2. Spherical roller bearing with setscrew lock;

3. Spherical roller bearing with adapter sleeve/taper lock

feature to attach them to the shaft.

Ball Bearings with setscrew lock - These are self-aligning

bearings and should present no alignment problems with

one exception: i.e., on Sealmaster bearings, there is a pin

beneath the grease fitting which prevents the bearing outer

race from rotating. Should this pin jam, the bearing loses

its alignment feature.

Common failure causes are (a) setscrews loosening and

shaft turning within the bearing inner race, and (b) crowned

bearing supports. Loosen one bolt and measure the clear-

ance between the bearing foot and the support. Add shims

to compensate.

Spherical Roller Bearings with setscrew lock - The self-

aligning characteristic of these bearings are inherent in the

spherical roller design. The closer that these bearings are

to perfect alignment, the cooler they will operate.

Common failure causes are the same as with the ball

bearings, mainly setscrews loosening and crowned bearing

supports.

Spherical Roller Bearings with adapter lock - Again, the self-

aligning feature is inherent in the spherical design. Good

alignment results in a cooler operating bearing. The faster

the bearing operates the more critical this becomes.

A common cause of failure is improper installation

practice. Removing too much radial internal clearance from

the bearing can cause preloading of the bearing with the

result of premature failure; and removing not enough inter-

nal clearance can allow the shaft to rotate within the

adapter sleeve with the result of noise, heat, and failure.

Properly tightened, this method of attaching a bearing to

a shaft is second only to an interference fit. Crowned

bearing supports can also preload these bearings and

should be checked by loosening one bolt and checking

the clearance between the bearing foot and the support.

Add shims to compensate.

Lubrication - The major cause of bearing failure is con-

tamination of grease, insufficient grease, or incompatibility

of grease. If a fan is to be stored for any length of time

at the job site, the bearings immediately should be filled

with grease while rotating the shaft and then the bearings

should be regreased and shaft rotated monthly. This will

prevent moisture, which condenses within the bearing, from

corroding the raceways. Most of the grease used on fan

pillow block bearings are lithium base. Use the greases

shown on the bearing decal. Do not mix greases with dif-

ferent type of bases, but always purge out the initial grease

having one base with the new grease having a different

base.

Initially, follow the lubrication instruction on the side of

the fan. The frequency of lubrication should be adjusted

depending on the condition of the old grease being

purged. This is the responsibility of the user. If the grease

is dirty, the lubrication frequency should be more often.

Bearing Noise – If a bearing is increasing in noise inten-

sity and/or vibration, it will probably result in failure.

Bearing Temperature – If a bearing temperature begins to

gradually rise, it will generally result in failure. A bearing

can operate up to 200°F and perform satisfactorily as long

as the temperature remains constant and the bearing

receives adequate lubrication. Remember that a roller bear-

ing under the same load and speed will be somewhat

noisier and run warmer than a ball bearing. This is normal.

Rough handling and /or dropping a fan can result in

brinelling the bearing. This appears as a clicking noise at

first, and then gradually worsens until failure occurs.

When replacing a bearing, always align the bearings first,

then bolt the pillow blocks to their support, rotate the

shaft, fasten the bearing to it. If the bearing is fastened to

the shaft first, tightening the pillow block blocks may bind

the shaft and preload the bearings.

Drive Problems

1. Belts improperly tensioned.

2. Drive alignment is poor. Check belts or coupling.

3. Coupling lubrication.

Motor Problems

1. Incorrect wiring.

2. Speed of fan is too high.

3. Parts improperly installed or binding.

4. Bearings improperly lubricated.

5. WR2 capability of motor is too low for application.

6. VFD compatible.

7. Cable and grounding correct.

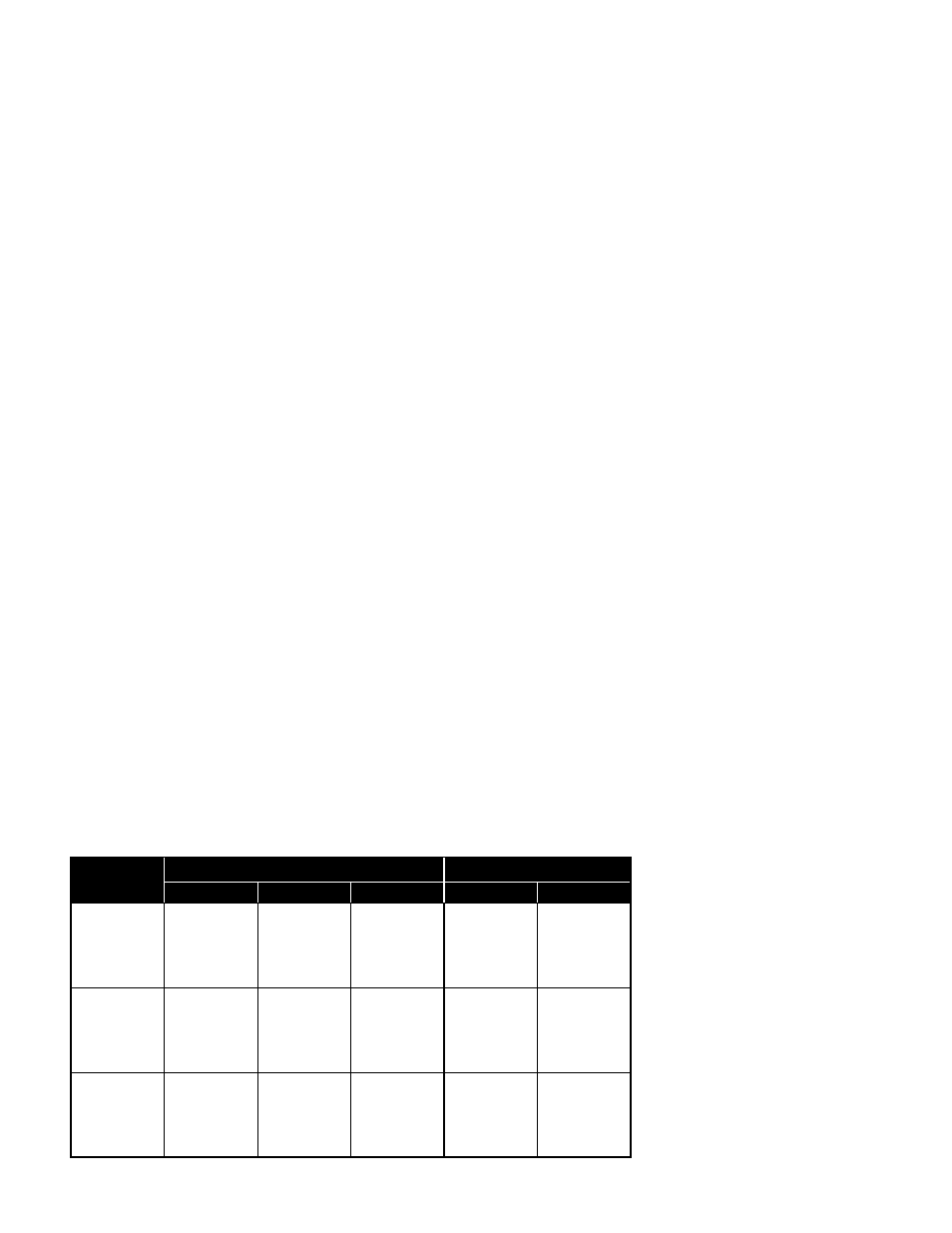

The torque values are for nonlubricated

fasteners and Browning Bushings.

For bearing setscrews, use manufacturer’s

recommendations.

If other bushings are used, utilize bushing

manufacturer's specifications.

Tolerance: /-

5%

For wheel setscrews use Grade 2 values.

+

Table 1. Tightening Torques (in lb-ft)

SIZE

FASTENER

TAPER BUSHINGS (DRIVE)

GRADE 2

GRADE 5

GRADE 8

SPLIT

QD

#10

—

—

—

—

6

1

⁄

4

-20

5.5

8

12

7.9

9

5

⁄

16

-18

11

17

25

16

15

3

⁄

8

-16

22

30

45

29

30

7

⁄

16

-14

30

50

70

—

—

1

⁄

2

-13

55

75

110

70

60

9

⁄

16

-12

—

—

—

—

75

5

⁄

8

-11

100

150

200

140

135

3

⁄

4

-10

170

270

380

250

225

7

⁄

8

-9

165

430

600

—

300

1-8

250

645

900

600

450

1

1

⁄

4

-7

500

1120

1500

—

—