Operation checklist, Troubleshooting guidelines, Troubleshooting problems – Aerovent IM-745 User Manual

Page 7

Aerovent IM-745

7

have the capability to be “Locked Out – Tagged Out”

by the service person working on the unit. The key to

the lock is to be retained by the service person to pre-

vent the accidental powering up of the fan while the

service person is working on the fan.

Appropriate hearing protection is to be used by all

personnel in the area of the fan while it is in operation.

Due to the nature of applications where FRP fans may

be used, it is highly probable that the airstream con-

stituents should not come in contact with body parts of

the service person or their clothing. Follow all local plant

safety requirements in regards to the exposure for the

specific airstream constituents present.

Fan housings equipped with optional access doors

should never be opened while the fan is in operation.

The close proximity of the fan wheel to the access door

opening is very dangerous when operating and can

present a fatal consequence.

Fans by their nature develop a negative pressure

(suction) at their inlet while in operation. Great care must

be taken to prevent this force from causing anything that

is near the inlet to be sucked into the rotating fan wheel.

Great harm to the fan as well as to the object taken

inside the fan can occur. This can also present a fatal

consequence. The same affect can be had due to the

high velocity air stream present which will also force

objects into the fan.

Even when the fan is not in operation, sometime

there are pressure differences present which can cause

the fan wheel to “windmill”. Great care must be exer-

cised to prevent injury when working on the fan. It is

advisable to temporarily block the wheel to prevent

unexpected rotation and potential injury from occurring.

OPERATION CHECKLIST

□ Verify that proper safety precautions have been followed.

□ Electrical power must be locked off.

□ Fan Assembly is properly grounded for static dissipation

option.

Check Fan Mechanism Components:

□ Nuts, bolts, and setscrews are tight.

□ Mounting connections are properly made and tightened.

□ Bearings are properly lubricated.

□ Wheel, drives, and fan surfaces are clean and tightened.

□ Rotating assembly turns freely and does not rub.

□ Check for fan/wheel overlap per Figure 2.

□ Drives mounted on correct shaft, properly aligned,

and properly tensioned.

Check Fan Electrical Components:

□ Motor is wired for proper supply voltage.

□ Motor was properly sized for power required by the

rotating assembly.

□ Motor is properly grounded.

□ All leads are properly insulated.

Trial “Bump”:

□ Turn on power just long enough to start assembly

rotating.

□ Check rotation for agreement with rotation arrow

□ Listen for any unusual sounds.

Run Unit Up To Speed:

□ Bearing temperatures are acceptable (<200°F) after

one to two hours of operation.

□ Check for excessive levels of vibration. Filter in readings

should be 0.15 in/sec (peak) or less.

After One Week Of Operation:

□ Check all nuts, bolts, and setscrews and tighten if

necessary.

□ Readjust drive tension if necessary.

TROUBLESHOOTING GUIDELINES

Use current safety practices when investigating fan or

system performance problems. General safe practices

and performance troubleshooting guidelines can be

found in AMCA Publications 410 and 202, respectively.

Fan application and field measurement procedures can

be found in AMCA Publications 201 and 203.

Below is a list of possible areas to check when air,

sound, or operational values do not match expectations.

Most fan problems can be pinpointed to one of these

common causes.

TROUBLESHOOTING PROBLEMS

Air Capacity Problems

1. Resistance of the system is not at design rating. If

resistance is lower than expected, both airflow and

horsepower may be up. If resistance is higher than

anticipated, air volume will be down.

2. Fan speed is not at design speed.

3. Air density at the fan inlet is not at the design value.

Also check air performance measurement techniques

and procedures.

4. Devices for air modulation are closed or plugged.

Also check filters.

5. Wheel mounted improperly or is rotating in reverse.

6. Parts of the system or fan have been damaged or

need cleaning.

Noise Problems

1. Air performance is incorrect and the fan is not at the

design point of operation. Fan is being forced to

operate in an unstable flow region.

2. Bearing failure. Check bearing lubrication, alignment,

and fastener tightness.

3. Supply voltage high or inconsistent supply frequency.

Adjustable frequency controllers (VFD) can generate

motor noise.

4. Objects which are installed in a high velocity air stream

can generate noise. This includes flow sensors, turning

vanes, etc.

5. Poor fan inlet conditions.

6. Acoustic or sound measurement procedure is incorrect.

Vibration Problems

1. Misalignment of drive components. Check belts or

coupling.

2. Poor foundation or mounting structure (resonance).

3. Foreign material attached to the rotating components.

4. Damaged rotating components (bearings, shaft, fan

wheel, sheaves, coupling, seals, etc.)

5. Broken, loose, or missing setscrews, bolts, or fasteners.

6. Vibration transmitted by another source.

7. Fan is operating in stall or unstable flow region.

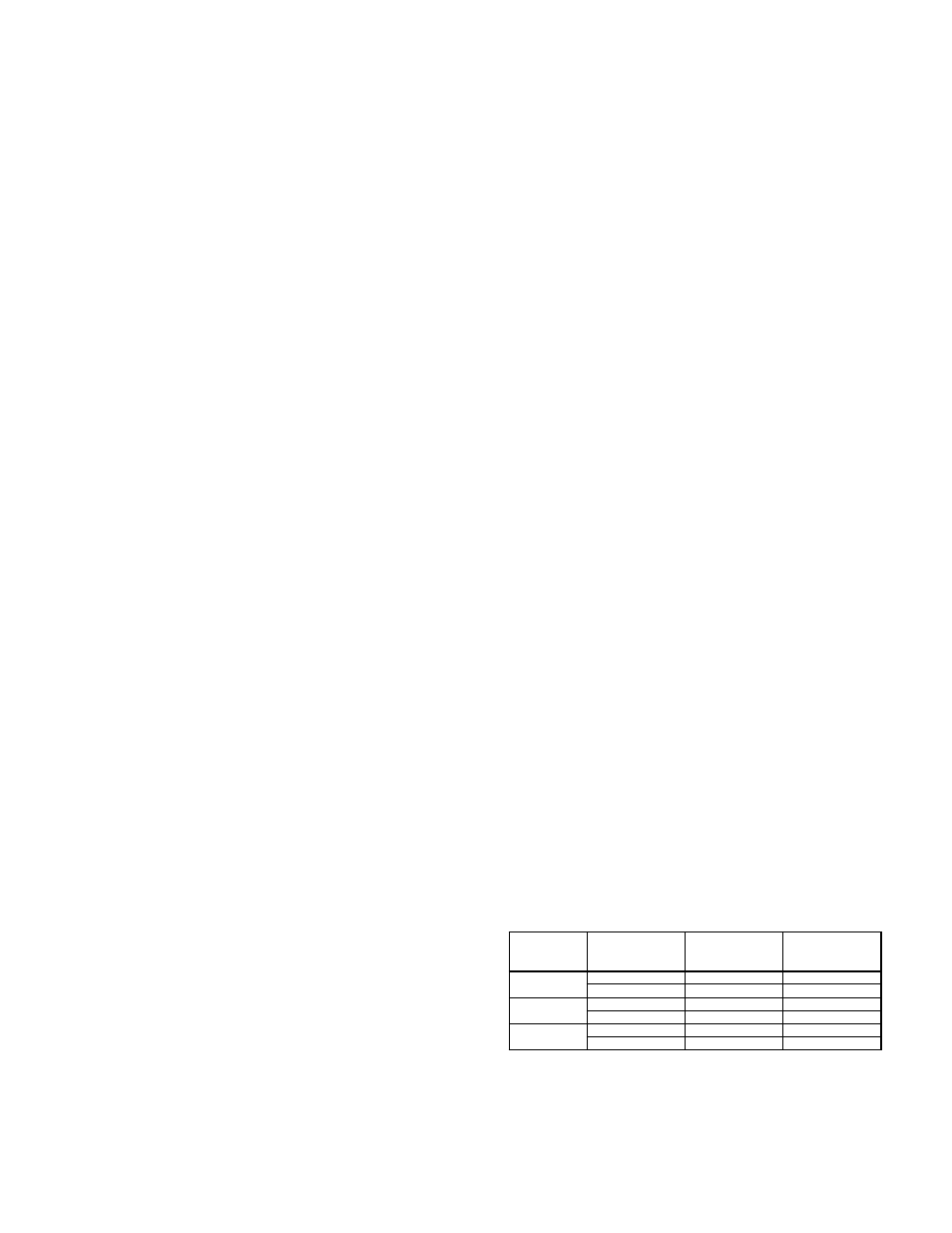

Figure 7. Vibration Guidelines

Seismic Vibration Velocity Limits for Operation In-Situ

Condition

Fan

Application

Category

Rigidly Mounted

mm/s (in./s)

Flexibly Mounted

mm/s (in./s)

Start-up

BV-3

6.4 (0.25)

8.8 (0.35)

BV-4

4.1 (0.16)

6.4 (0.25)

Alarm

BV-3

10.2 (0.40)

16.5 (0.65)

BV-4

6.4 (0.25)

10.2 (0.40)

Shutdown

BV-3

12.7 (0.50)

17.8 (0.70)

BV-4

10.2 (0.40)

15.2 (0.60)

Value shown are peak velocity, mm/s (inches/s), Filter out.

Table taken from ANSI/AMCA Standard 204-05, Table 6.3.

AMCA defines BV-3 for applications up to 400 HP; BV-4 for applica-

tions over 400 HP.