Limitations of warranties and claims, Warning – Aerovent IM-745 User Manual

Page 10

WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

LIMITATIONS OF WARRANTIES and

CLAIMS

Seller warrants to the original purchaser that the

goods sold hereunder shall be free from defects in

workmanship and material under normal use and service

(except in those cases where the materials are supplied

by the buyer) for a period of one year from the date of

original installation or eighteen (18) months from the date

of shipment, whichever occurs first. The liability of seller

under this warranty is limited to replacing, repairing, or

issuing credit (at cost, F.O.B. factory and at seller’s

discretion) for any pars which are returned by buyer

during such period provided that:

a. Seller is notified in writing within ten (10) days

following discovery of such defects by buyer, or

within ten (10) days after such defects should

be reasonably have been discovered, whichever

is less;

b. The defective unit is returned to seller, trans-

portation charges prepaid by buyer.

c. Payment in full has been received by seller or

said products; and

d. Seller’s examination of such unit shall disclose

to its satisfaction that such defects have not

been caused by misuse, neglect, improper installation,

repair, alteration, act of God, or accident.

e. Seller cannot guarantee sound pressure levels or

dBA.

No warranty made hereunder shall extend to any

seller product whose serial number is altered, effaced,

or removed. Seller makes no warranty, express or

implied, with respect to motors, switches, controls, or

other components of seller’s product, where such com-

ponents are warranted separately by their respective

manufacturers. THIS WARRANTY IS EXPRESSLY IN

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. In no event shall seller be liable to buyer for

indirect, incidental collateral, or consequential damage of

any kind. (BUYER’S FAILURE TO PAY THE FULL

AMOUNT DUE WITHIN SIXTY (60) DAYS OF DATE OF

INVOICE SHALL OPERATE TO RELEASE SELLER FROM

ANY AND ALL LIABILITY OR OBLIGATION ARISING

PURSUANT TO ANY WARRANTY, EXPRESS OR

IMPLIED, WHETHER STATUTORY OR OTHERWISE,

INCLUDING

ANY

IMPLIED

WARRANTY

OR

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, MADE IN CONNECTION WITH ANY

CONTRACT HEREUNDER. BUYER AGREES THAT SUCH

FAILURE TO PAY SHALL CONSTITUTE A VOLUNTARY

WAIVER OF ANY AND ALL SUCH WARRANTIES

ARISING PURSUANT TO SUCH CONTRACT.)

1MPP11/09

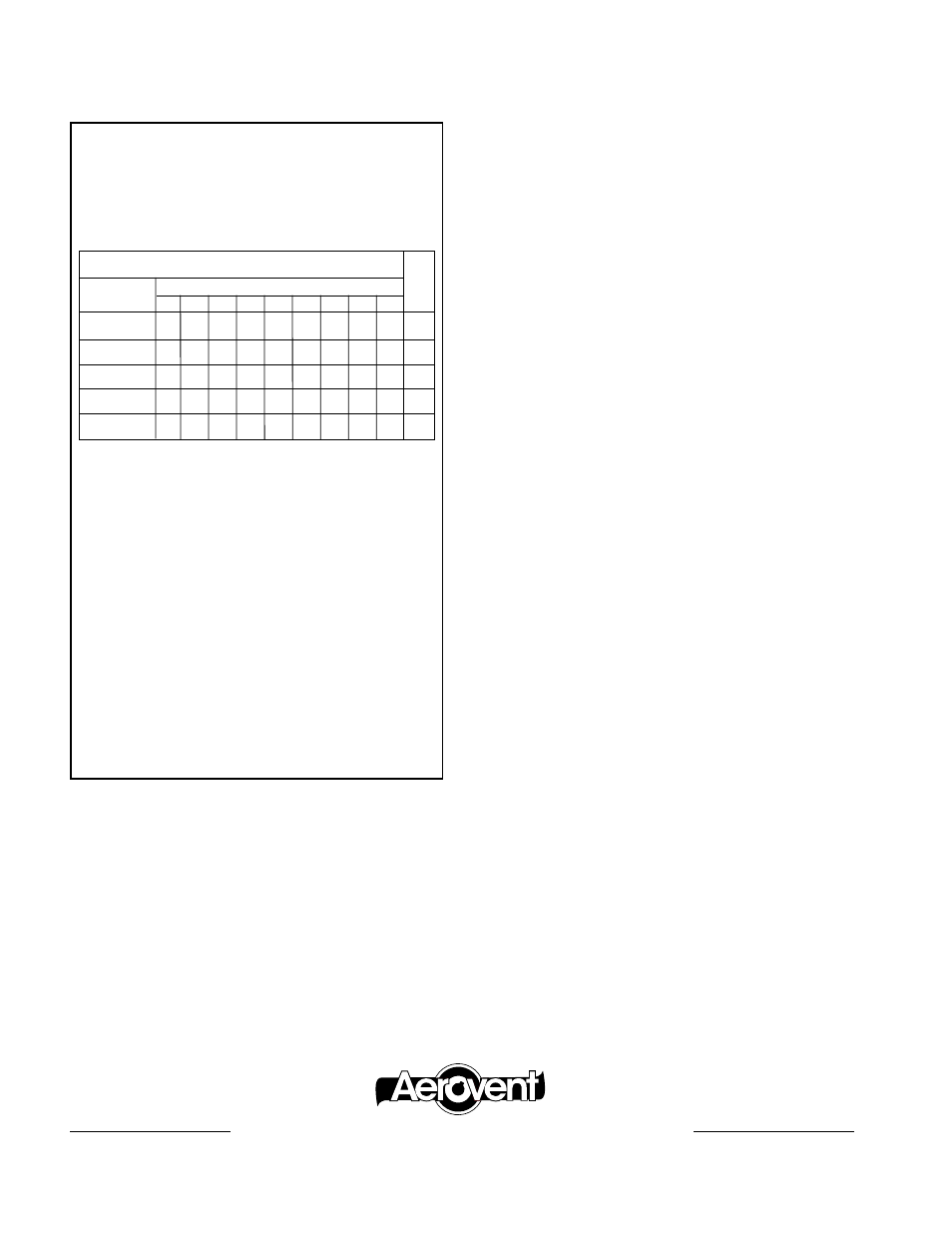

Figure 11. Safety & Lubrication Instructions for Fans

with Spherical Roller Bearings with Split Pillow

Block Housings

WARNING

1. This equipment must not be operated without proper guarding of

all moving parts. While performing maintenance be sure remote

power switches are locked off. See installation manual for recom-

mended safety practices.

2. Before starting: Check all setscrews for tightness, and rotate wheel

by hand to make sure it has not moved in transit.

*Suggested lubrication interval under ideal continuous operating condi-

tions. Remove bearing cap and observe condition of used grease after

lubricating. Adjust lubrication frequency as needed. Use one-half of

listed interval for vertical shaft applications or for 24 hour operation.

Hours of operation, temperature, and surrounding conditions will affect

the relubrication frequency required. Clean and repack bearings annu-

ally. Remove old grease, pack bearing full and fill housing reservoir

on both sides of bearings to bottom of shaft.

1. Lubricate with a high quality NLGI No. 2 lithium-base grease hav-

ing rust inhibitors and antioxidant additives, and a minimum oil

viscosity of 500 SUS at 100°F (38°C). Some greases having these

properties are:

Shell - Gadus S2 V100 2

Exxon - Ronex MP

Mobil - Mobilith SHC100

Mobil - Mobilith SHC220

2. Lubricate bearings prior to extended shutdown or storage and

rotate shaft monthly to aid corrosion protection.

3. Purge or remove old grease when changing lubrication brands or

types.

Static Oil Lubrication

1. Use only high quality mineral oil with a VG grade indicated on the

customer submittal drawing.

2. Static oil level should be at the center of the lower-most roller

(Do not overfill.)

3. Complete lubrication change should be made annually.

Relubrication Schedule (Months)*

Spherical Roller Bearing - Split Pillow Blocks

Speed (RPM)

Shaft DIA

500

750 1000 1500 2000 2500 3000 3500 4000

1

7

⁄

16

" thru 1

15

⁄

16

"

6

4

1

⁄

2

4

4

3

1

⁄

2

2

1

⁄

2

2

1

⁄

2

1

1 0.50 oz.

(35 – 50)

2

3

⁄

16

" thru 2

13

⁄

16

"

5

4

1

⁄

2

4

2

1

⁄

2

2

1

⁄

2

1

1

⁄

2

1

⁄

2

1

⁄

4

1

⁄

4

0.75 oz.

(55 – 70)

2

15

⁄

16

" thru 3

15

⁄

16

"

4

1

⁄

2

4

3

1

⁄

2

2

1

⁄

2

1

1

⁄

2

1

1

⁄

2

2.00 oz.

(75 – 100)

4

7

⁄

16

" thru 4

15

⁄

16

"

4

4

2

1

⁄

2

1

1

⁄

2

4.00 oz.

(110 – 135)

5

7

⁄

16

" thru 6

15

⁄

16

"

4

2

1

⁄

2

1

1

⁄

2

7.00 oz.

(140 – 180)

Grease

to be

added

at each

interval

®