Bearing maintenance, Drive installation, Drive maintenance – Aerovent IM-745 User Manual

Page 4: Flexible coupling installation

4

Aerovent IM-745

BEARING MAINTENANCE

Proper lubrication of the fan bearings helps assure

maximum bearing life. All fans are equipped with decals

indicating relubrication intervals for normal operating condi-

tions. Figures 9, 10 and 11 illustrate the lubrication sched-

ules for ball bearings, solid pillow block spherical roller

bearings, and split pillow block spherical roller bearings,

respectively. Note that all speeds shown do not apply to

all shaft sizes in that group. Consult the factory if in doubt

of maximum speed for a particular bearing. Note that every

installation is different and the frequency of relubrication

should be adjusted accordingly.

On applications where there is high moisture or heavy

dust, the lubrication frequency may need to be doubled or

tripled to adequately protect the bearings.

Observation of the conditions of the grease expelled from

unit ball or roller bearings at the time of relubrication is

the best guide as to whether regreasing interval and

amount of grease added should be altered.

Spherical roller bearings with split pillow block housings

should be lubricated until grease purges or overheating

may result. Follow the lubrication interval and amount

noted in Figure 11. Spherical roller bearings with split pil-

low block housings should be serviced once per year.

Remove cap, clean out old grease, and replace by filling

the bottom half of the housing 1/3 full.

Greases are made with different bases. There are syn-

thetic base greases, lithium base, sodium base, poly urea

base, etc. Avoid mixing greases with different bases. They

could be incompatible and result in rapid deterioration or

breakdown of the grease. The lubrication sticker identifies

a list of acceptable lubricants. All bearings are filled with

a lithium based grease before leaving the factory. When

the fans are started, the bearings may discharge excess

grease through the seals for a short period of time. Do

not replace the initial discharge because leakage will cease

when the excess grease has worked out. Sometimes the

bearings have a tendency to run hotter during this period.

This is no reason alarm unless it lasts over 48 hours or

gets very hot (over 200°F). When relubricating, use a suf-

ficient amount of grease to purge the seals. Rotate bear-

ings by hand during relubrication.

DRIVE INSTALLATION

Mount drives as follows:

1. Slip (do not pound) proper sheave and its bushing

onto corresponding shaft (position per Figure 3).

CAUTION: placing fan sheave on motor can over

speed the wheel and cause structural failure.

2. Align sheaves with a straightedge extended along

sheave face, just making contact in two places on

outside perimeters of both sheaves (reference Figure

4). This “four-point” alignment may also be checked

with a string tied to the shaft behind one of the

sheaves. The string is then pulled taut over the faces

of the sheaves to check the alignment at the four

points at the outside perimeters. Each sheave should

be rotated about one-half revolution during the check

to look for excessive runout or a bent shaft.

3. Install and tighten the belts. Run the drive for a few

minutes to seat the belts. When tightening the belts,

slide the motor in to slip the belts on. Do not use

a pry bar, as this may damage the belt cords.

Tighten the belts to the proper tension. Ideal tension

is just enough tension so that the belts do not slip

under peak load. Many drives are provided with ten-

sioning data which identifies the load to apply at the

center of the span and the allowable deflection from

this force. This may be checked visually (look for a

slight bow on slack side), or listen for a squeal on

startup, indicating that the belts are too loose.

Recheck sheave alignment.

4. After initial installation of belts, recheck belt tension

again after a few days and adjust tension as needed.

(New belts require a break-in period of operation.)

DRIVE MAINTENANCE

V-belt drives need periodic inspection, re-tensioning,

and occasional belt replacement. Look for dirt buildup,

burrs, or obstructions when inspecting drives. These can

cause premature belt or drive replacement. If burrs are

found, use fine emery cloth or a stone to remove the

burr. Be careful that dust does not enter the bearings.

Check the sheaves for wear. Excessive slippage of

belts on the sheaves can cause wear and vibration.

Replace worn sheaves with new ones. Carefully align

sheaves to avoid premature sheave failure.

Observe belts for signs of wear. If fraying or other

wear is observed to be mostly on one side of the belts,

the drives may be misaligned. Reinstall the drives accord-

ing to instructions given for “Drive Installation”. Never use

belt dressing on any belts. Make sure the sheaves and

belts are free from all forms of lubricants.

Always replace the entire set of v-belts and never mix

used belts with new belts. Follow instructions given for

“Drive Installation”.

FLEXIBLE COUPLING INSTALLATION

These instructions are general for the installation of

several types of flexible couplings and should not be used

as a substitute for more specific manufacturer’s instruc-

tions. The coupling manufacturer’s installation data is avail-

able and will give specific dimensions for alignment limits,

lubricants, etc. Refer to Item 7 in “Fan Installation” section

for alignment requirements.

Before preparing to mount the coupling, make sure that

all bearings, shaft seal, or other shaft mounted components

have been installed on the shaft.

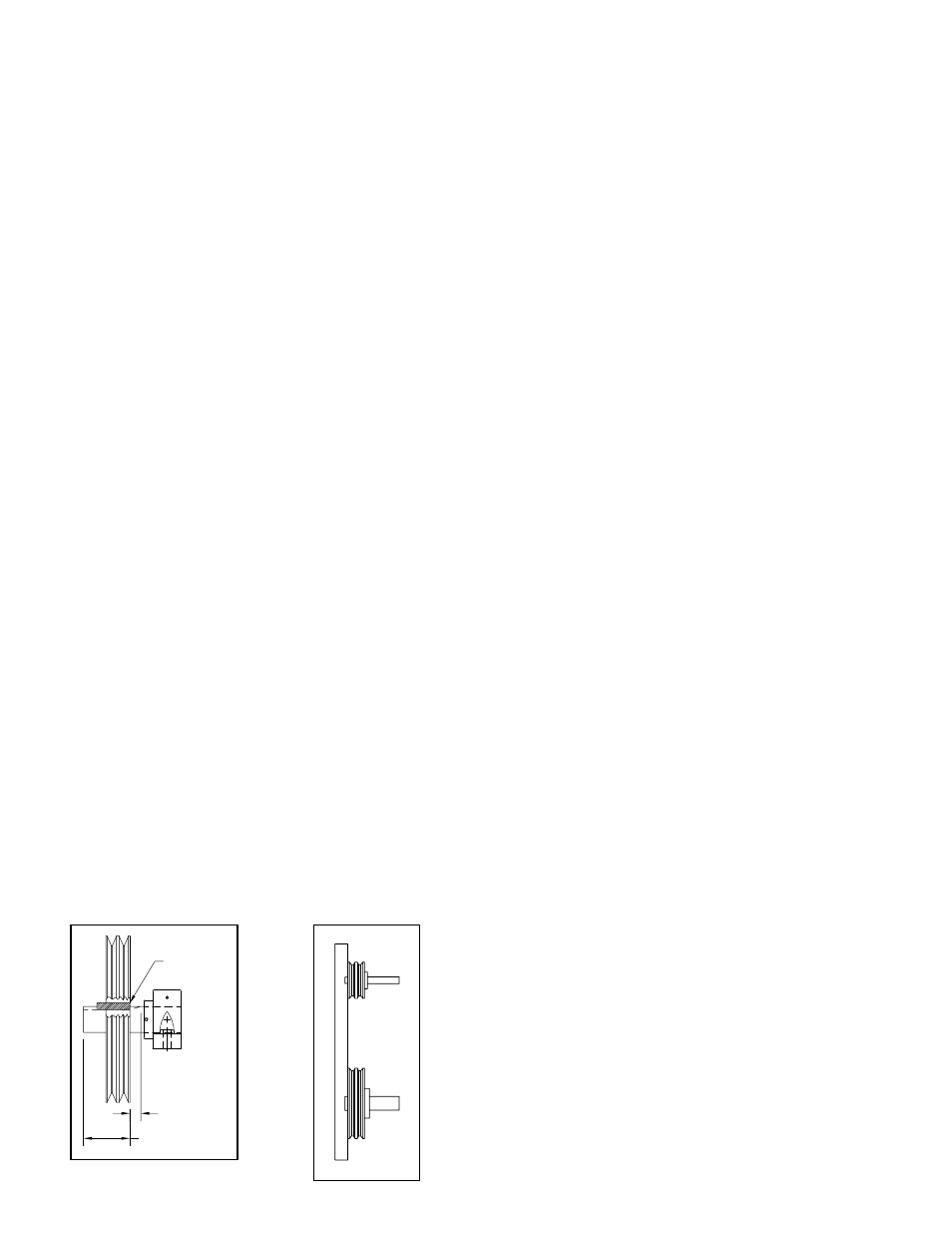

When mounting and keying the interference fit coupling

halves to the shaft, follow supplied instructions for heating

and shrink fitting. Set the coupling halves for the normal

gap specified by the manufacturer. Coupling gap is illus-

trated in Figure 5.

The two types of misalignment are illustrated in Figure

5. Typically angular alignment is checked with feeler gages

between the hub faces. When angular alignment has been

adjusted to within manufacturer’s specification by shim-

ming, if necessary, then parallel alignment can be checked

with a straightedge and feeler gages on the hub halves’

O.D. When shimming has brought parallel alignment within

specification, angular alignment and gap should again be

checked, and adjustments made if necessary. A dial indica-

SHEAVE LINED

UP WITH END

OF KEYWAY

RUN OUT

RUN OUT OF

KEYWAY

KEYWAY LENGTH

Figure 4.

Sheave Alignment

Figure 3.

Sheave Position