General motor maintenance, Frp maintenance, Wheel and shaft maintenance – Aerovent IM-745 User Manual

Page 5

Aerovent IM-745

5

tor or laser alignment method may be used to more

accurately take the measurements described above.

Special adjustments may need to be made for couplings

used with some equipment. As an example, when cou-

plings are used with motors which have sleeve bearings,

the coupling may require provisions for limiting end float.

Larger drives may grow vertically in operation (due to

thermal expansion) requiring the driver side to be set

slightly low when at ambient temperature. Refer to spe-

cific instruction manuals or assembly drawings.

Thoroughly clean the coupling halves after completion

of alignment. Reassemble the coupling and tighten cover

bolts, washers, and nuts. Lubricate per manufacturer’s

recommendations.

GENERAL MOTOR MAINTENANCE

The three basic rules of motor maintenance are keep

the motor clean, keep the motor dry, and keep the motor

properly lubricated.

Keeping the motor and its windings clean is important

because dirt and dust serve as thermal insulation. Heat

normally dissipated by the motor is trapped causing over-

heating and/or premature failure. Blow dust and dirt out of

windings and off the motor periodically. Use a clean and

dry low pressure (50 psig) airstream so that winding dam-

age does not occur. Keep the area surrounding the motor

open so that air can circulate through the motor cooling

fan.

Motors should be kept dry to avoid electrical short

circuits. Motors kept in storage for long periods of time can

have moisture condense on the windings. Be certain the

motor windings are dry before energizing the motor.

Lubrication requirements are normally attached to the

motor. Do not overlubricate. Motor lubricants are often not

the same as the fan bearing lubricant. Some smaller motors

are lubricated for life. Motor bearing lubrication, if required,

must follow a rigorous schedule. Motors less than 10 hp

running about eight hours a day in a clean environment

should be lubricated once every five years; motors 15 to

50 hp, every three years; and motors 60 to 150 hp,

yearly. For motors in a dusty or dirty environment or run-

ning 24 hours a day, divide the service interval by two. If

the environment is very dirty or has a high ambient tem-

perature, then divide the service interval by four.

Motors controlled by variable frequency drives (VFD)

should be wired in accordance with the VFD manufacturer’s

instructions. The motor must be grounded to earth and

proper shielded cabling must be used. Motor shaft ground-

ing rings should be considered to minimize shaft voltage

from arcing through the motor bearings.

FRP MAINTENANCE

Corrosion Resistance – The type of reinforcement fiber

used in making the laminate structure will influence its

weight, strength, and also the wheel maximum safe speed.

The resin selected will influence the corrosion resistance of

the laminate and hence the product durability. The Aerovent

standard resin used for manufacturing wheel components

is the epoxy vinyl ester product Derakane 510A40 from

Ashland. The Aerovent standard resin used for manufactur-

ing housing components is the polyester product Hetron

92FR from Ashland with the option of using Derakane

510A40. Both products (without addition of antimony triox-

ide) have a flame spread rating less than 25 as tunnel

tested per ASTM E84.

See the “Corrosive Atmosphere Guide” that is located

within Aerovent Catalog 745 for suggested resin to use in

various corrosive environments. Final selection of the resin

should always be based upon customer’s experience and/

or testing conducted with desired fume concentration and

temperature. Additional corrosion resistance information is

available from Ashland at ashland.com.

Perform periodic visual inspection of the FRP laminate

to determine there is no adverse deterioration occurring

which will compromise the product’s structural integrity.

Periodic cleaning can prolong product life and should be

investigated.

Abrasion Resistance – Fans constructed of FRP materials

are intended for clean air service with humidity less than

100% or for air laden with corrosive fumes. FRP laminate

is inherently “softer” than carbon steel and stainless steel.

FRP products should not be used to convey air which

contains particulate or water (liquid or fog). Severe erosion

can occur if these items are present in the airstream. The

resin rich outer surface is subject to wear and if this layer

is compromised, the corrosive fumes can then attack the

reinforcement fiber. The combination of corrosion and abra-

sion can quickly lead to product failure.

Perform periodic visual inspection of the FRP laminate

to determine there is no adverse deterioration occurring

which will compromise the product’s structural integrity.

Weather Resistance – FRP products installed outdoor with-

out adequate protection are subject to damage from local

weather conditions. This can include impact damage result-

ing from hail or windblown objects, surface chalking or

discoloration from ultraviolet light exposure, and reduced

strength due to temperature effects resulting from high

ambient temperature and solar radiation combined with high

internal air temperature.

WHEEL and SHAFT MAINTENANCE

Periodically inspect the fan shaft and FRP wheel for

buildup, corrosion, and signs of excess stress or fatigue.

Dust or chemical deposits will usually build up on

the wheel evenly and they present no problem to per-

formance or operation until they become thick enough

to break away in crust-like pieces. When this happens,

the wheel may be thrown out of balance and the result-

ing vibration could be serious. When removing this

crustaceous accumulations, care should be taken not to

clean the fan wheel with sharp objects which might

damage the laminated surface and reduce its corrosion

resistance. Replace the wheel and shaft sub-assembly if

it shows signs of excessive wear or damage to the

laminate.

The fan wheel and shaft sub-assembly is factory bal-

anced and then the entire fan assembly is test run to

assure vibration levels are within tolerance. It is not

uncommon for the fan wheel to require some trim bal-

ancing after installation or after some period of time in

operation. Addition of FRP weights to the backplate or

frontplate can be made to bring the vibration levels back

within specification.

Check the interface between the shaft sleeve and the

wheel backplate. This joint is critical to prevent infiltra-

tion of corrosive fluids to the shaft and hub. Replace

the sub-assembly if needed.

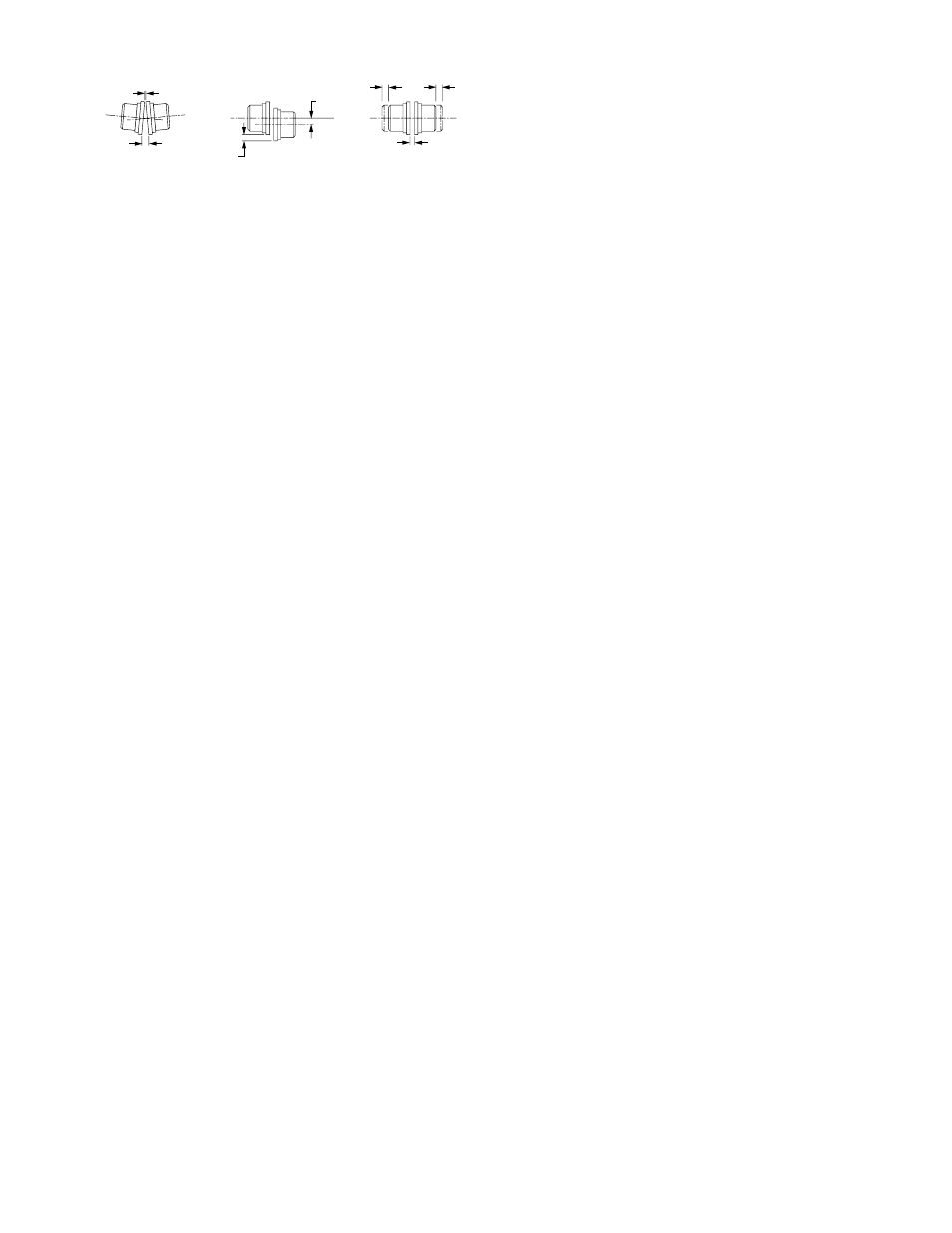

Figure 5. Coupling Installation

Y

X

P

P

F

F

GAP

ANGULAR

PARALLEL

GAP AND

MISALIGNMENT

MISALIGNMENT

END FLOAT

X-Y = ANGULAR MISALIGNMENT

P = PARALLEL OFFSET (MISALIGNMENT)

F = END FLOAT