Fan installation, Bearing installation – Aerovent IM-745 User Manual

Page 3

Aerovent IM-745

3

motor speed. This is especial true if the structure supports

more than one fan.

Fan inlet and outlet ducting should have independent

support. Do not use the fan to support ducting as the fan

housing or pedestal may become distorted or cracked. Flex

connectors at the fan inlet and discharge will isolate the

duct loads from the fan plus eliminate transmission of vibra-

tion. Use stainless steel fasteners with large washers under

the head and nut to increase the load bearing area. Do not

tighten the fasteners to the point of crushing the flange.

FAN INSTALLATION

Follow proper handling instructions as given earlier.

1. Move the fan to the final mounting position.

2. Remove skid, crates, and packing materials carefully.

3. If vibration isolation is to be used, place isolation base

on mounting bolts. Line up holes in fan base with

bolts.

4. Place the fan on mounting structure. Carefully level

the unit (checking the level on the fan shaft) on the

foundation and shim as necessary using stainless

steel shims on both sides of each anchor bolt. Be

careful not to force the fan to the mounting structure/

foundation. This may cause the bearings to become

misaligned or pinched, which can cause vibration and

premature failure.

5. Check the alignment of the bearings. Shim or reposi-

tion the bearings if necessary.

6. Check face alignment of sheaves on belt driven units

(reference Figure 4). Check tension of belts to see if

it is sufficient. Sheaves on belt driven fans are often

provided with taperlock bushings. When tightening

bushing bolts, proceed in a progressive manner to

avoid cocking the tapered surfaces between the bush-

ing and the sheave.

7. Check alignment of factory mounted couplings, as

they are subject to misalignment during shipping and

installation. Realign to within 0.002" offset and paral-

lel. Allow for thermal growth of the motor by setting

the motor 0.001" low for each inch of shaft up to

0.005". NOTE: Grid-type and gear-type couplings

require lubrication.

8. Check the tightness of the foundation bolts, motor

bolts, sheaves, and bearings. Make sure there is no

rubbing or binding and that the wheel-inlet cone

clearances are correct.

9. Check that bearings are fully lubricated. For spherical

roller bearings with split pillow block housings, the

bottom half of the housing should be 1/3 full of

grease. For oil lube bearings, the oil level should

submerge the bottom-most roller halfway.

10. Install any accessories that were shipped loose from

the factory.

11. Grouting is the final installation step. Check all stain-

less steel shims before grouting to make sure the fan

is resting evenly on all points with anchor bolts

secured to hold the shims. Use shims with sufficient

space allowed for working the grout. The concrete

foundation should be clean and well moistened before

pouring grout. Use a commercial grade non-shrinking

grout and be especially sure when pouring grout that

the anchor bolt sleeves are filled. Refer to Figure 8

for a detail of a proper foundation, grout allowance,

and anchor bolt sleeve.

BEARING INSTALLATION

The following section gives some general instructions

on bearing installation. When bearings are field installed,

the specific installation manual for the bearings should be

followed carefully. Always make sure to check the fan

assembly drawing or instructions for location of the non-

expansion and expansion bearings. The position of these

bearings cannot be interchanged.

Spherical Roller Bearings with Split Pillow Block

Housing

1. The bearings should be disassembled, taking care not

to interchange parts between bearings. Parts of one

bearing are generally not interchangeable with parts

from another bearing.

2. The lower bearing housing should be bolted loosely

to the pedestal and seals, bearing, and adapter sleeve

assembly should be placed loosely on the shaft.

3. The rotor assembly with the seals and bearings

should next be positioned over the housing and care-

fully placed into the lower housing.

4. The thrust locking ring should be installed in the bear-

ing closest to the drive sheave or coupling unless

otherwise noted in the drawing.

5. When installing adapter sleeves, tighten for reduction

in clearance per manufacturer’s instructions.

6. Bend down a tab on the lockwasher after finishing

adjustment.

7. Grease or oil according to manufacturer’s instructions.

8. Install the bearing housing cap and cap bolts. Tighten

bearing housing cap bolts and bearing mounting

bolts. Torque to bearing manufacturer’s instructions.

Solid Pillow Block

1. Slide shaft in bearing bore to proper location. Note:

Shaft should slide easily if self-aligning feature of the

shaft is within its limits. Sling the rotor assembly into

place and loosely bolt the bearings in place.

2. When bearings are in place, torque the base bolts

using values from Table 1, and tighten the collar

setscrews to manufacturer’s specification.

3. Grease the bearings per manufacturer’s instructions.

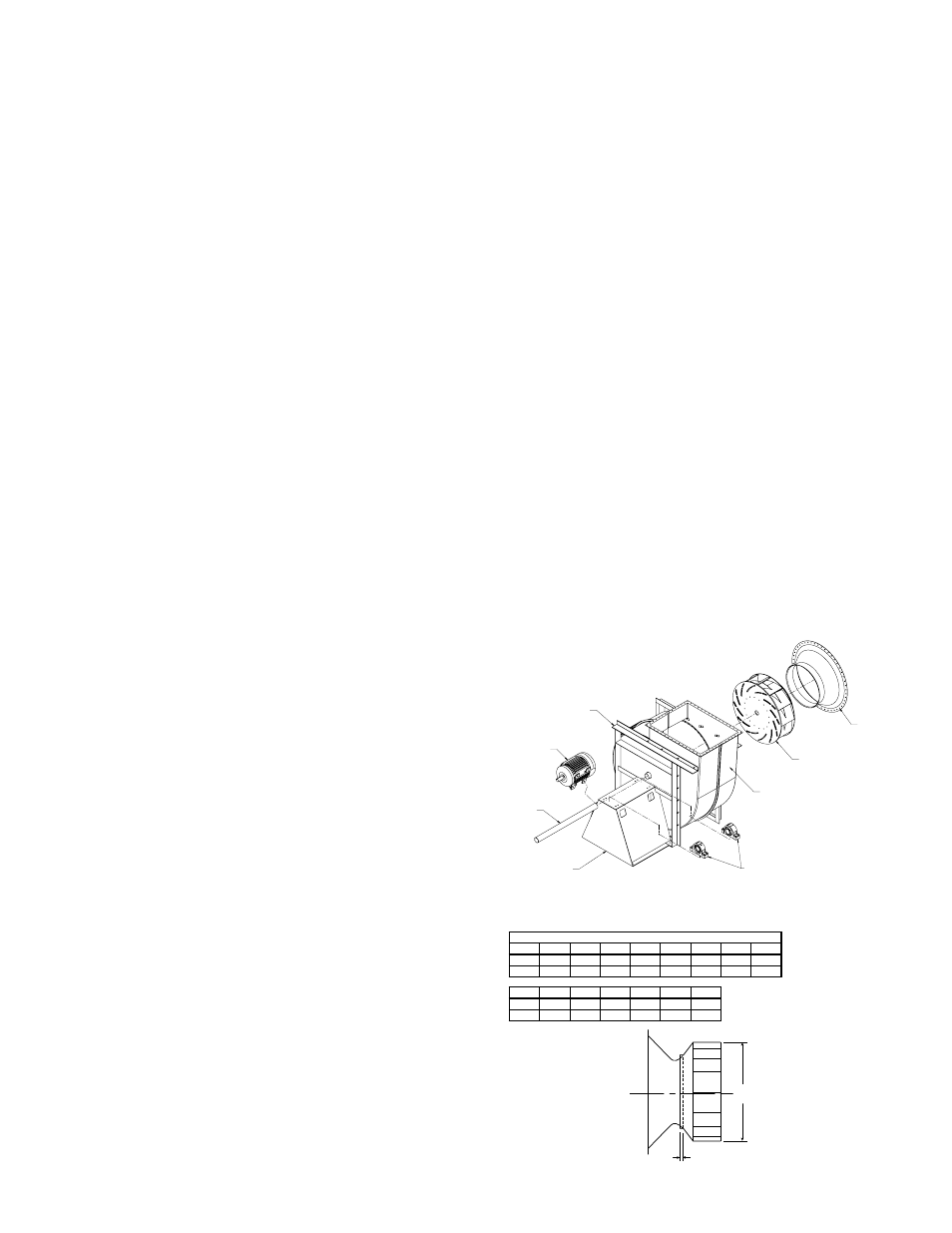

HOUSING

SUPPORT STAND

(HOUSING FRAME)

WHEEL / IMPELLER

INLET FUNNEL

PEDESTAL

SHAFT

MOTOR

BEARINGS

Figure 1.

Figure 2. Wheel Placement

A

DIA

B

BCSF Wheel Placement

Size

165

182

200

222

245

270

300

330

A

16.50 18.25 20.00 22.25 24.50 27.00 30.00 33.00

B

0.44

0.56

0.63

0.69

0.75

0.88

0.97

1.06

Size

365

402

445

490

542

600

A

36.50 40.25 44.50 49.00 54.25 60.00

B

0.94

1.03

1.13

1.25

1.38

1.56