Snorkel TL49J-01-sn008562+ User Manual

Page 33

29

TL49J

513868-000

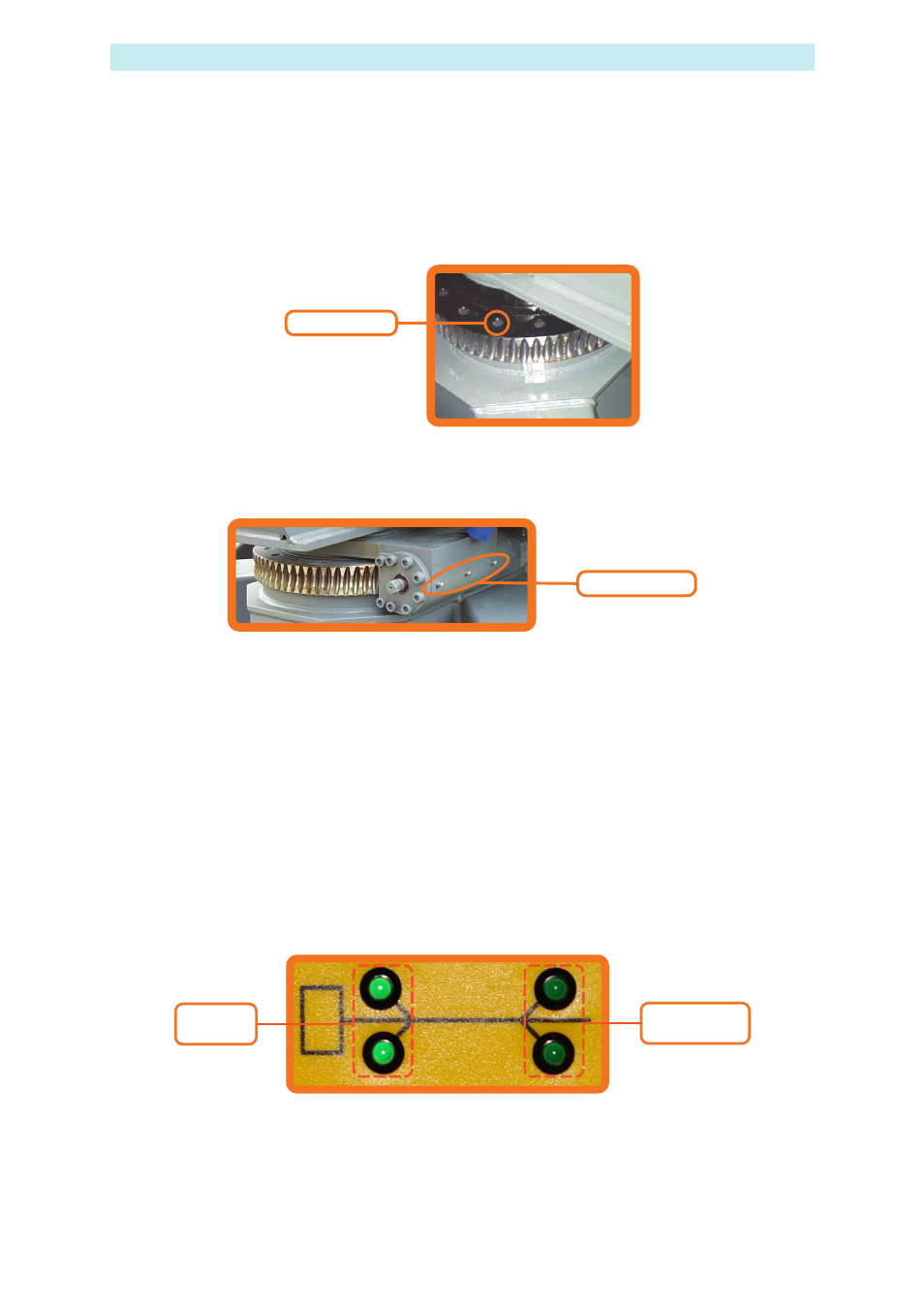

Slew Drive Gears.

The slew drive gear is designed to be largely maintenance free. However, we recommend the

gear teeth be greased on a monthly basis with a high pressure grease. Additionally, the ring

gear and gear box should be greased on a six monthly basis. The grease nipple for the ring

gear is on the top face of the slew gear, set between the fixing bolts. It can be accessed by

lifting one of the side covers, and slewing the structure appropriately.

MAINTENANCE

Grease Nipple

The ring gear should be inspected on a six monthly basis for excessive play. It is unlikely there

will be any wear if the machine is maintained correctly.

Grease Nipples

To check the gear, place a payload of approximately 80Kg in the platform. Elevate the lower

boom to approximately half way. Then gently elevate the top boom, whilst observing the ring

gear. Excessive wear will be observed by noticing more than 0.5mm movement between the

inner and outer bearing rings.

Checking Limit Switch Operation.

The limit switches require no maintenance, other than a visual inspection, on a pre operation

basis. This is an important check, to ensure the switch is not mechanically damaged, and the

roller is always in contact with the cam, when not under load.

The switch operation can be simply checked, by observing the LED display when deploying

the stabilizers. As an outrigger foot touches the ground and becomes loaded, the appropriate

light will change to green. This indicates that the switch contact has operated correctly.

Outriggers NOT

under load

Outriggers

under load

If the LED displays green at any other time then the machine must not be operated, until the

fault is rectified.