Snorkel MB26-sn435-999 User Manual

Page 22

2. Operation & Specifications

2-13

1. Never approach the MB20N from the front or rear while fork lifting.

2. Use maximum forklift tilt as soon as possible when raising the MB20N/26.

3. If travelling over sloped or uneven ground it is strongly recommended to temporarily tie the

MB20N jib mount structure to the forklift mast as a safety precaution.

4. The MB20N/26 may be lifted by forklift subject to the following strict procedure.

5. Ensure that the mast and jib are fully stowed and that the pothole bars are fully retracted

(raised)

.

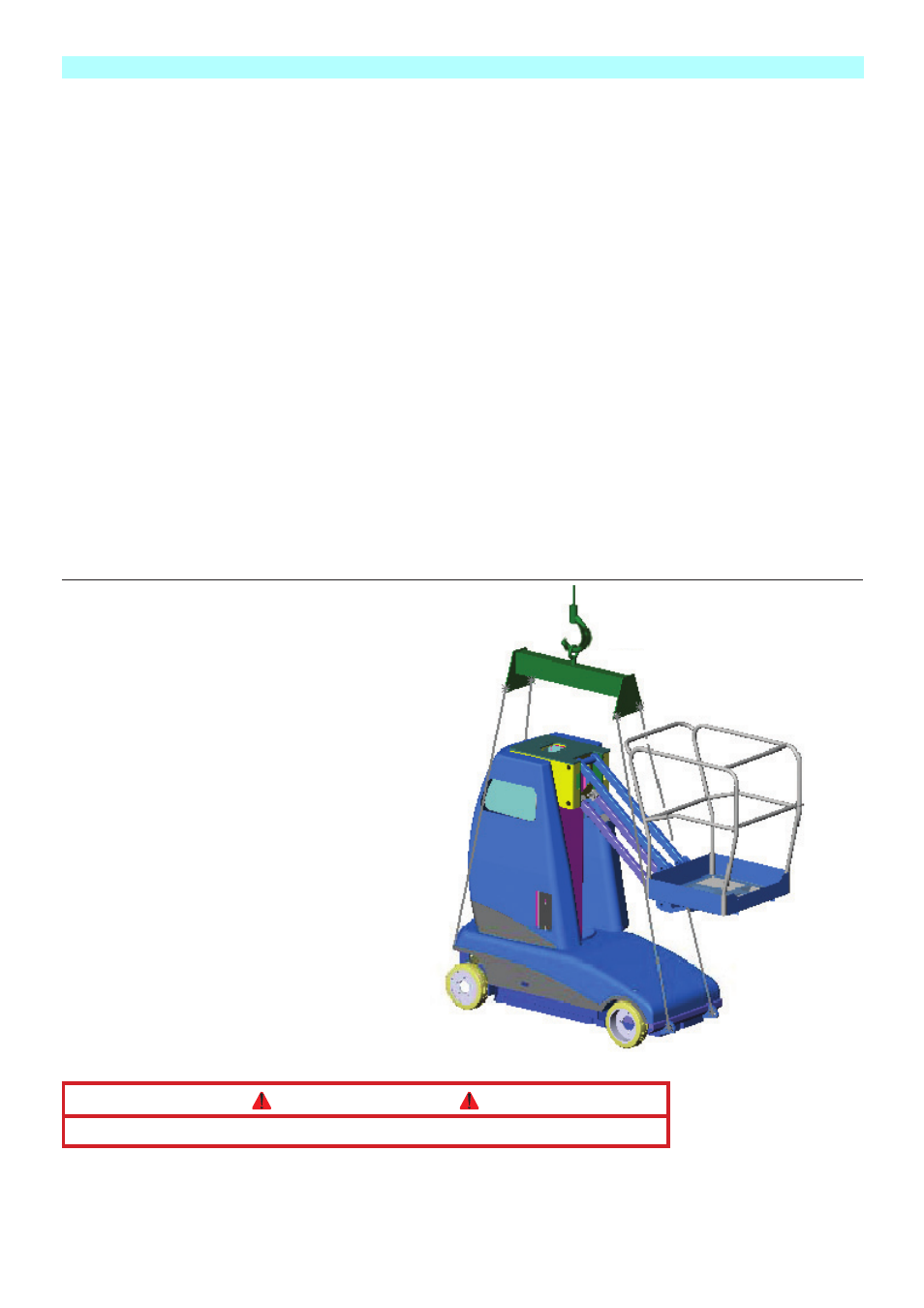

LIFTING BY CRANE

The MB20N/26 may be lifted by an overhead hoist/crane subject to the following strict

procedure.

Raise the jib to clear the lifting straps as shown.

Use 4 separate lifting straps connected to a spreader beam. DO NOT use a lesser number

of threaded straps as these could slip and lead to instability. The recommended minimum

capacity of EACH of the 4 straps is 2 tonne and the minimum length of each strap is

2 metres. Damage to the covers and/or cage rails can occur if a spreader beam is not

deployed during a crane lift.

Figure 4: Lifting by Crane

Apply the straps via 2

tonne shackles to each

of the 4 lifting lugs on the

chassis.

C A U T I O N

DO NOT apply lifting straps to any other part of the machine.

SPREADER

BEAM CAPACITY

4 TONNE