Warning – Snorkel AB46JE User Manual

Page 33

Chapter 8 – Prestart Inspection

AB46JE – 0260072

29

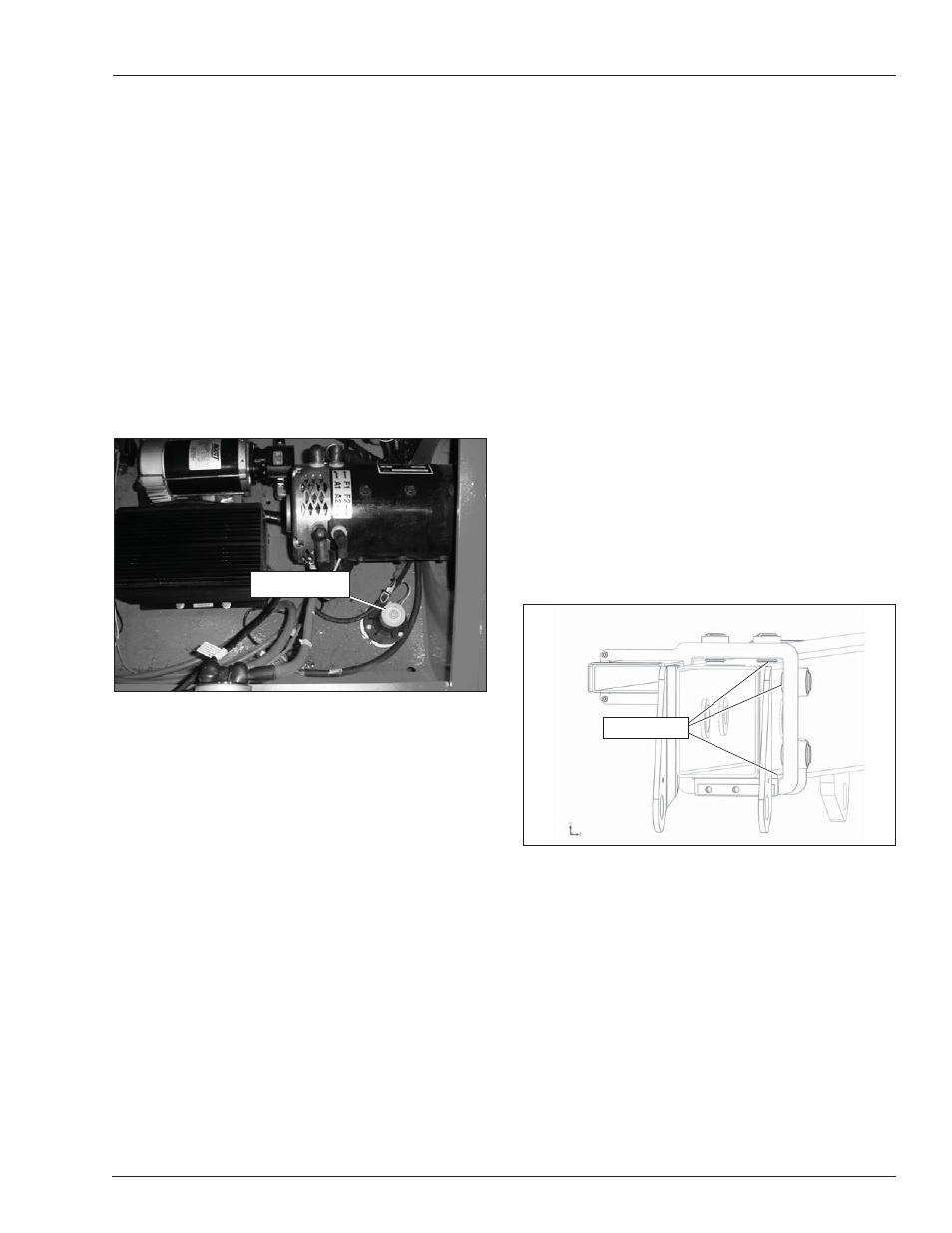

Level Sensor

Use the following procedure to test the level sensor:

1. Position the aerial platform on a smooth, flat, level

surface.

2. Remove all persons and materials from the plat-

form.

3. Start the machine and raise the riser boom above

horizontal, approximately 15 to 20 degrees.

4. Remove the drive control compartment cover. The

level sensor is in the right side (refer to Figure

8.10).

5. Pull the level sensor to the side as far as possible to

activate the tilt alarm.

Figure 8.10 – Level Sensor

A

Warning

The potential for an accident increases when safety

devices do not function properly. Death or serious

injury could result from such accidents. Do not alter,

disable, or override any safety device.

6. If the alarm does not sound, remove the machine

from service until the problem is corrected.

7. Lower the riser boom.

Flashing Light

The machine may be equipped with an optional flashing

light mounted to the top of the counterweight.

To inspect the flashing light:

1. Turn the battery disconnect switch on.

2. At the lower controls, pull the emergency stop button

outward and turn the start switch on.

3. Operate any control function and visually check to

see that the light is flashing approximately one flash

per second.

Level Sensor

Level Sensor

Note

There is not an off switch for the flashing light.

Structures

Visually inspect all weldments and related components.

It is important to inspect the fasteners that connect the

components.

Weldments

To inspect the weldments:

1. Visually inspect all weldments for abnormal wear,

abrasion, or deformation that could cause interfer-

ence between moving parts.

2. Inspect the welds on the structural components.

Pay particular attention to boom welds. The area to

be inspected should be clean and free of dirt and

grease.

3. Look for visible cracks in the welds and at the weld

to parent material joints. A bright light may be used

to provide adequate visibility of the inspection area.

Boom Slide Pads

The main boom has slide pads (refer to Figure 8.11)

between the main and tip boom sections.

Figure 8.11 – Slide Pads at Tip End of Boom

To inspect the slide pads:

1. Use the lower controls to raise the main boom near

horizontal. Extend the tip boom about 1

′ (30 cm).

2. Visually inspect the slide pads to make sure they are

securely fastened to the main boom.

3. Inspect the surface where the pads contact the tip

boom. The paint must be in place with no signs of

bare metal.

Slide Pads

Slide Pads