Warning – Burnham 81433101R16-1/10 User Manual

Page 25

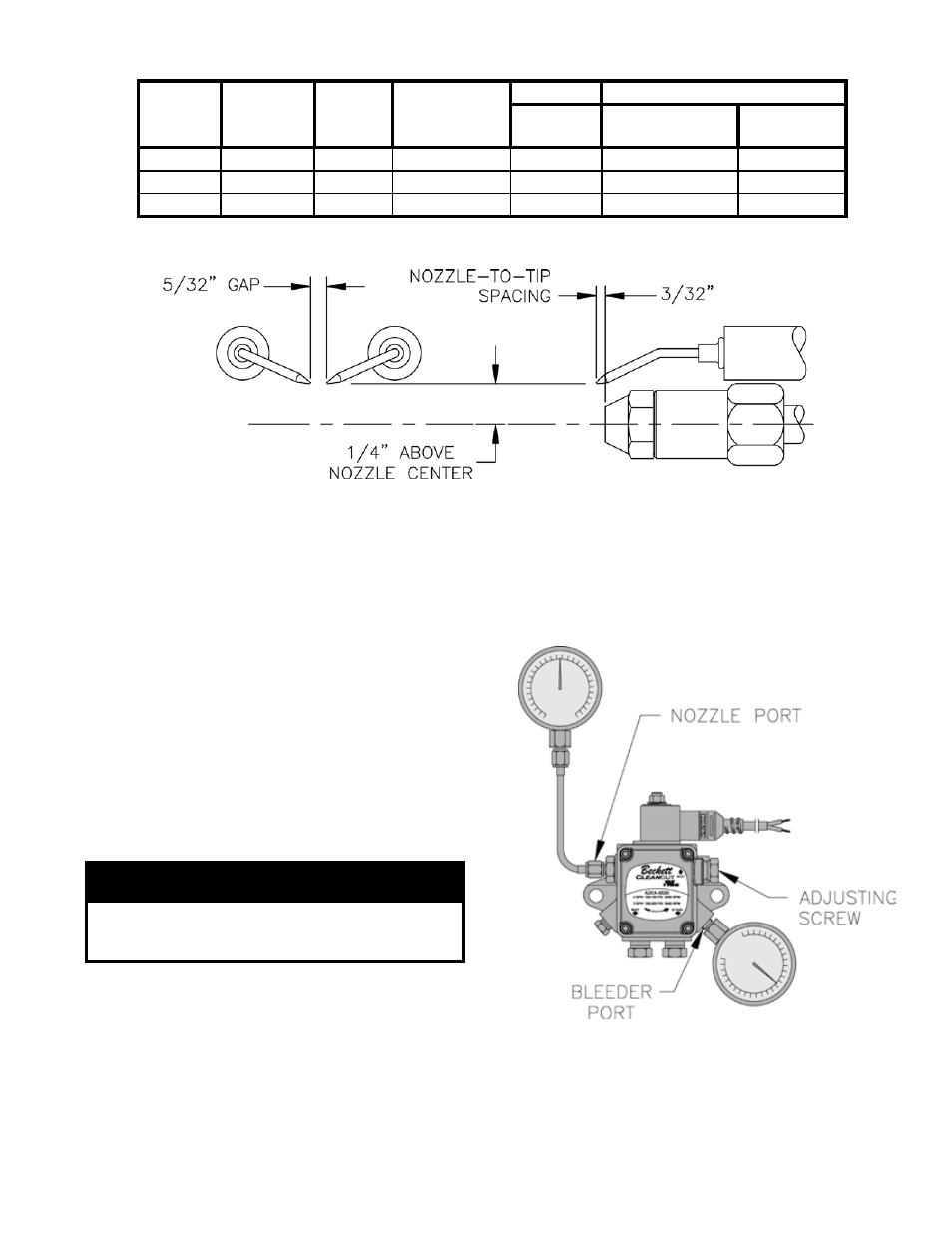

c. Upon reinstallation of the nozzle line assembly,

check that head/air plate setting number pointer

lines up with a number on the scale, which

matches a value shown in Table 6 for a particular

boiler/burner model.

2. Open all shut-off valves in the oil supply line to the

burner.

3. Attach a plastic hose to fuel pump vent fitting and

provide a container to catch the oil.

4. REMOVE GAUGE PORT PLUG from fuel pump

and install pressure gauge.

5. REMOVE TEST PLUG IN FLUE COLLAR.

6. Close the service switch to start the burner. If the

burner does not start immediately, check the manual

overload switch on the motor, if so equipped, and

the safety switch of the burner primary control.

WARNING

Very hot flue gases come out of sight hole when

boiler is operated without sight plug installed.

Always wear proper eye protection.

7. Bleed the fuel unit when the burner motor starts

rotating. To bleed, loosen the vent fitting (with

plastic hose attached) and catch the oil in an empty

container. Continue to bleed for 15 seconds after oil

is free of air bubbles. Tighten the vent fitting when

all the air is purged. NOTE: Bleeding might not be

necessary with a two pipe system. When vent fitting

is closed, burner flame should start immediately.

Boiler

Model

Firing Rate

(GPH)

Burner

Model

Delavan Oil

Nozzle

Settings

Air Gate

Pump Pressure

(PSIG)

Turbulator

LEDV1

0.60

BF3

0.50 - 60° A

4.0

145

0

LEDV2

1.00

BF5

0.85 - 60° A

5.0

145

1.0

LEDV3

1.25

BF5

1.00 - 60° A

6.5

145

3.0

Table 6A: Riello BF Burner Settings

Figure 0A: Electrode Tip Gap & Spacing

8. INSTALL PRESSURE GAUGE

a. Either, remove plastic hose and oil pump vent

fitting, then, install a reliable pressure gauge

into vent fitting port, or install the gauge into the

nozzle port. See Figure 20B.

Figure 0B: Checking / Adjusting Fuel

Pump Pressure

9. CHECK / ADJUST OIL PRESSURE

a. Check oil pressure to correspond to a specified

value for a particular LEDV boiler model. Refer

to Table 6.