V. electrical and sequence of operations – Burnham 81433101R16-1/10 User Manual

Page 18

18

V. Electrical and Sequence of Operations

A

. ELECTRICAL

1. Install wiring and ground boiler in accordance with

requirements of authority having jurisdiction, or in

absence of such requirements the National Electrical

Code, ANSI/NFPA 70, and/or the CSA C22.1

Electric Code.

2. A separate electrical circuit must be run from

the main electrical service with an over-current

device/disconnect in the circuit. A service switch is

recommended and may be required by some local

jurisdictions.

3. Wiring should conform to Figures 15 and 15A.

4. Thermostat heat anticipator setting = 0.3 amp.

B

. SEQUENCE OF OPERATIONS

1. General

. A call for heat by the thermostat energizes

the L7248C limit control which in turn energizes the

R7184P primary control to turn on the burner. The

circulator will operate as long as there is a call for

heat. If the call for heat is not satisfied and the high

limit setting is reached, the circulator will continue

to operate, and the burner will stop until the high

limit circuit is closed by a drop in boiler water

temperature.

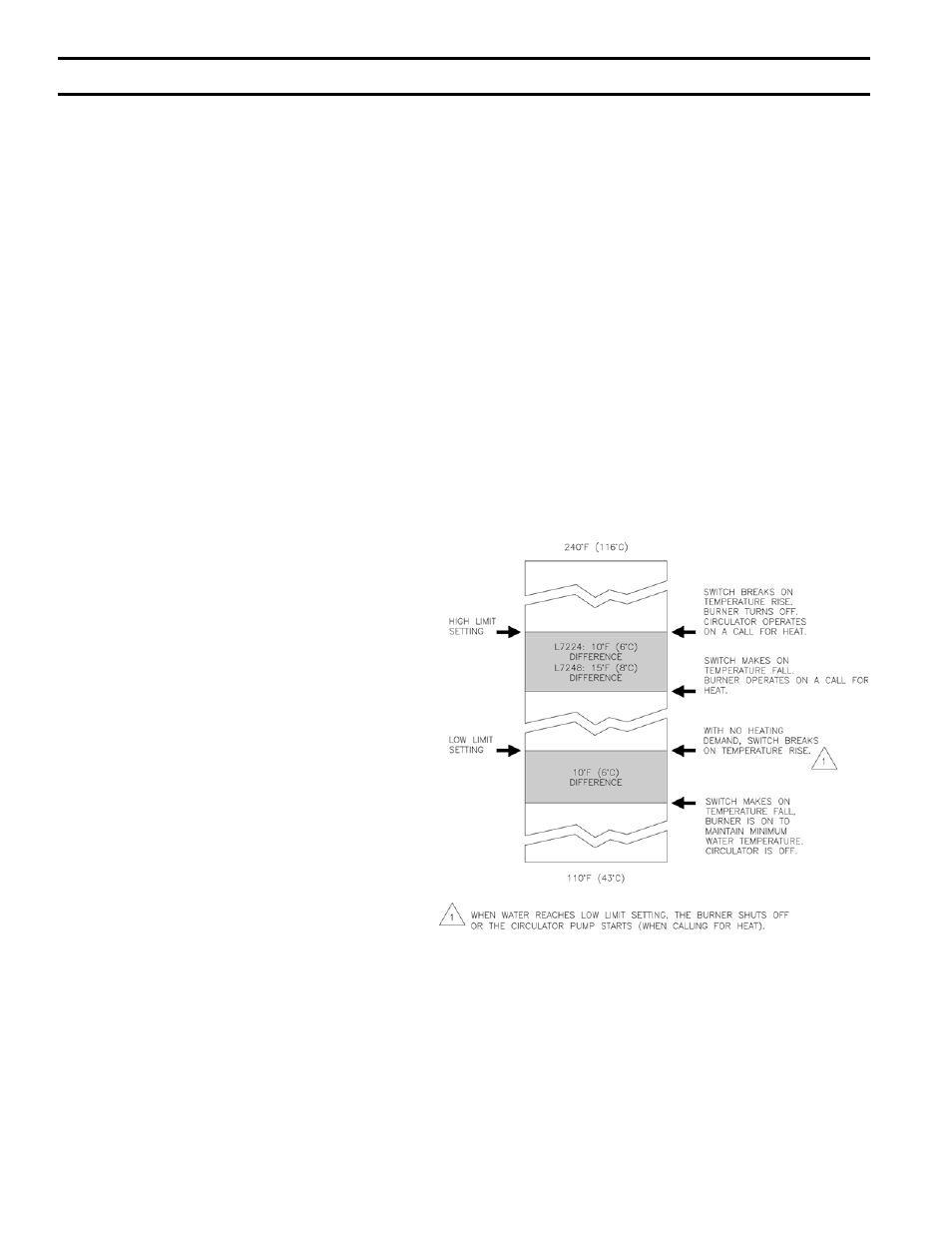

2. L7248C Combination Limit control.

The switching action within the L7248C control has

one setting, the high limit. The switching relay is

controlled by the low voltage room thermostat. On

a call for heat, the relay contacts close to complete

the line voltage circulator circuit and also the burner

circuit if the boiler water temperature is below the

high limit setting. The high limit switch shuts off

the burner if boiler water temperature exceeds the

high limit setting. See Figure 14.

3. R7184P Oil Primary Control.

The R7184P operates the oil burner motor, solenoid

oil valve, and the electronic ignitor in response to a

call for heat from the L7248C limit control.

a. A call for heat will energize the burner motor and

electronic ignitor.

b. After a 15 second pre-purge period, in which

time a draft is established in the flueways, the oil

valve is opened.

c. If the burner ignites within 15 seconds from the

time the oil valve opens and the CAD cell senses

a flame, the electronic ignitor is de-energized

and the burner will operate until the call for

heat is satisfied or the setting of the high limit is

reached.

d. A manual reset button is provided to reset the

safety switch after lockout.

e. When the call for heat ends, or the CAD cell

fails to sense a flame, the oil valve will close.

The combustion blower will continue to operate

for a postpurge period of approximately two (2)

minutes.

4. CAD Cell.

The Beckett AFII burners used on the LEDV Series

are supplied with a C554A Cadmium Sulfide (cad

cell) Flame Detector to monitor the burner flame and

shut down the burner on ignition failure or on flame

failure during the run cycle. On either failure, the

manual reset button on the R7184P will be tripped.

Figure 14: L48/L4 Setpoint and Differential

Switching Action