Vi. oil piping, Notice – Burnham 81433101R16-1/10 User Manual

Page 21

1

VI. Oil Piping

A.

General

1. Use flexible oil line(s) so that Swing Door can be

opened without disconnecting oil supply.

2. A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper fuel

oil filter is recommended for the lowest (.6 GPH)

firing rate application to prevent nozzle fouling.

3. Use Flared fittings only. Do not use compression

fittings.

4. Use of a high efficiency micron oil filter (Garber

or equivalent) in addition to conventional filter is

highly recommended.

B.

Single-pipe Oil Lines.

1. Standard burners are provided with single-stage

3450 rpm fuel units with the bypass plug removed

for single-pipe installations.

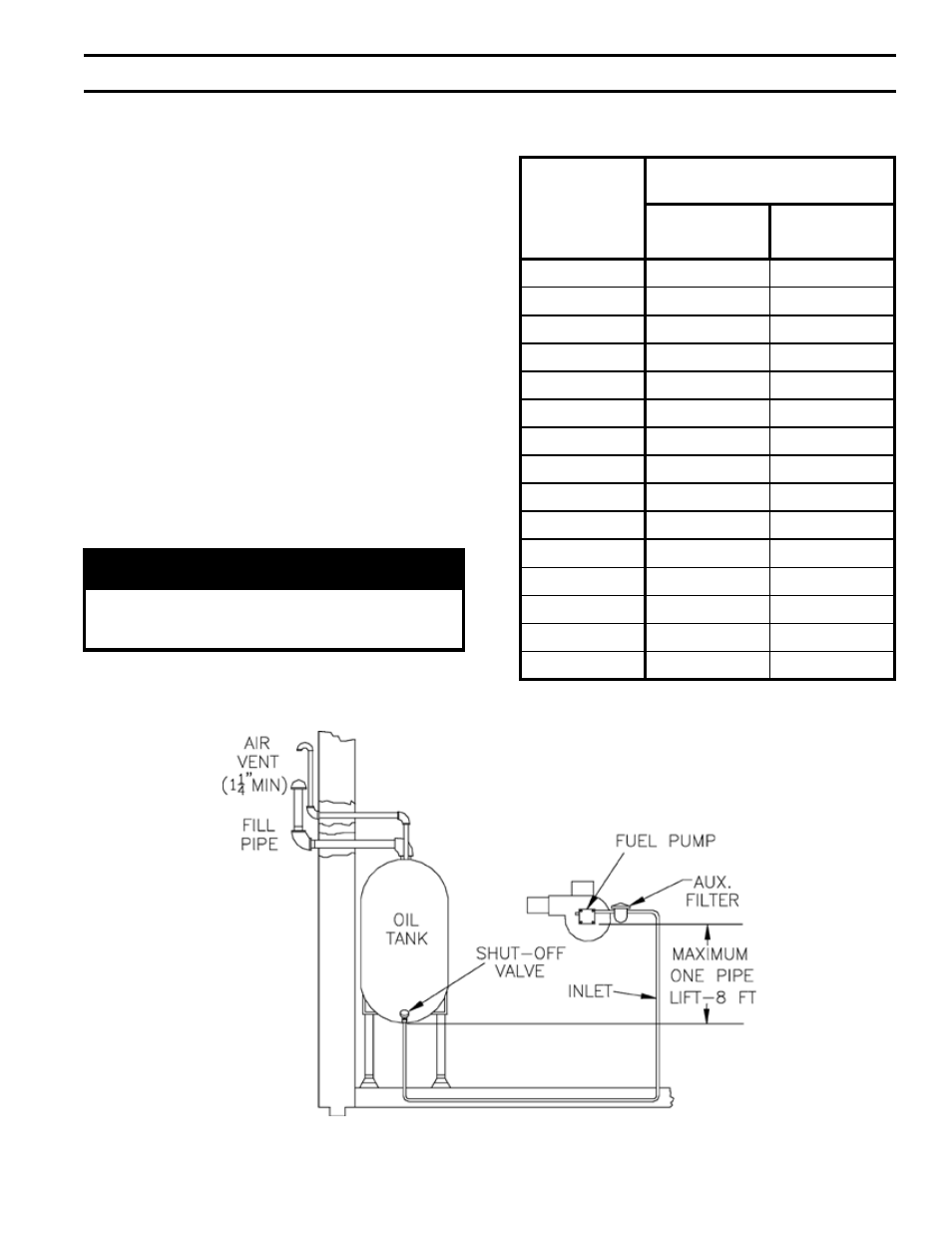

2. The single-stage fuel unit may be installed single-

pipe with gravity feed or lift. Maximum allowable

lift is 8 feet. See Figure 16.

NOTICE

Single-pipe installations must be absolutely airtight

or leaks or loss of prime may result. Bleed line and

fuel unit completely.

Figure 16: Single-Pipe Installation

Lift "H"

Maximum Length of Tubing

"H" + "R"

3/8" OD

Tubing (3 GPH)

1/" OD

Tubing (3 GPH)

0'

84'

100'

1'

78'

100'

2'

73'

100'

3'

68'

100'

4'

63'

100'

5'

57'

100'

6'

52'

100'

7'

47'

100'

8'

42'

100'

9'

36'

100'

10'

31'

100'

11'

26'

100'

12'

21'

83'

13'

---

62'

14'

---

41'

Table : Single-Stage Units (340 RPM) -

Two Pipe Systems