Burnham 81433101R16-1/10 User Manual

Page 10

10

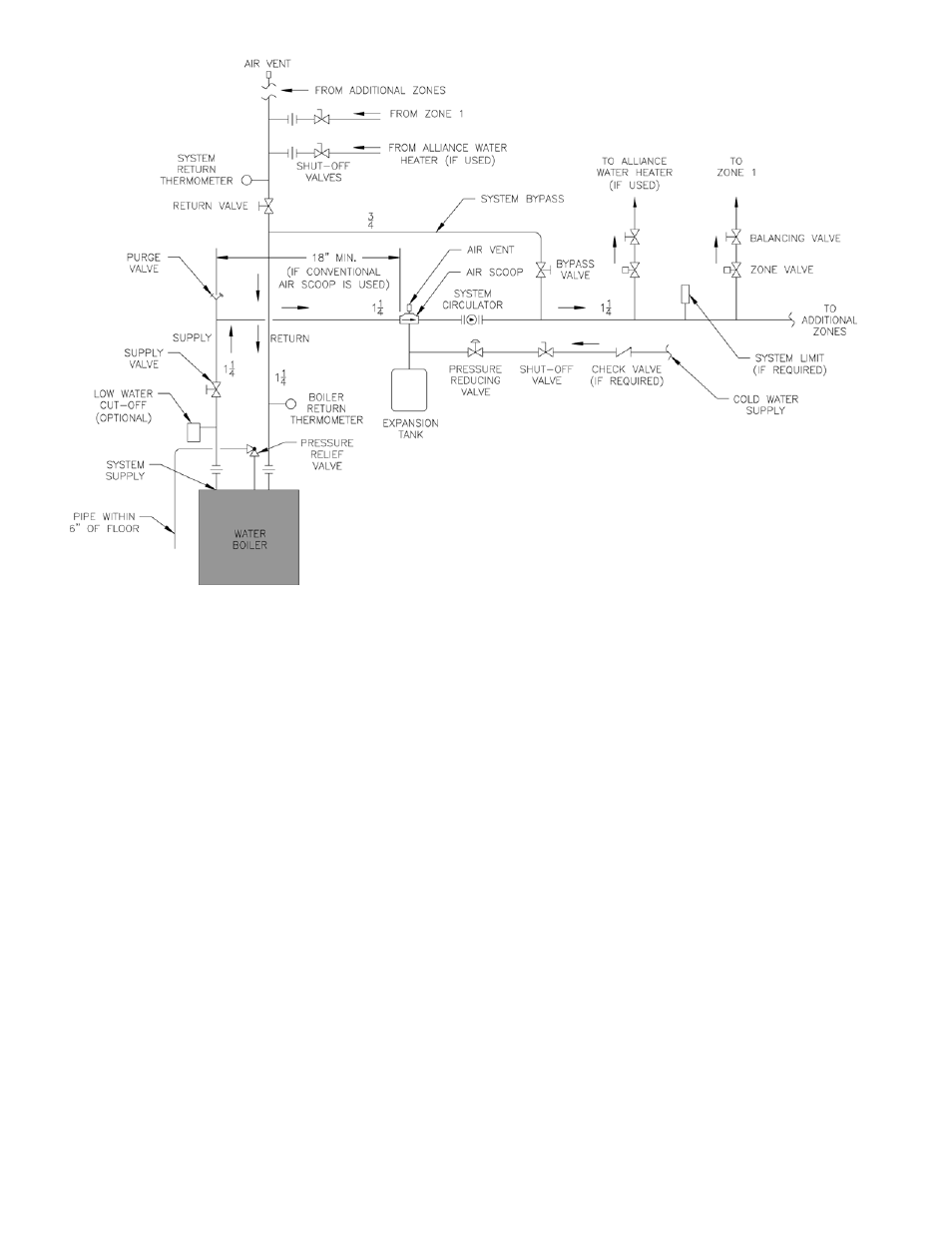

Figure : Recommended Water Piping for Zone Valve Zoned Heating Systems

D

. Install Drain Valve in return piping. See Figure 5.

E.

Oil, grease, and other foreign materials which

accumulate in new hot water boilers and a new or

reworked system should be boiled out, and then

thoroughly flushed. A qualified water treatment

chemical specialist should be consulted for

recommendations regarding appropriate chemical

compounds and concentrations which are compatible

with local environmental regulations.

F

. After the boiler and system have been cleaned and

flushed, and before refilling the entire system add

appropriate water treatment chemicals, if necessary, to

bring the pH between 7 and 11.

G.

Fill entire heating system with water and vent air

from system. Use the following procedure on a Series

Loop System equipped with zone valves. (See Figure

5).

1. Close isolation valve in boiler supply piping.

2. Isolate all circuits by closing zone valves or

balancing valves.

3. Attach a hose to hose bib located just below

isolation valve in boiler supply piping. (Note

- Terminate hose in five gallon bucket at a suitable

floor drain or outdoor area).

4. Starting with one circuit, open zone valve.

5. Open hose bib.

6. Open fill valve (Make-up water line should be

located directly above isolation valve in boiler

supply piping).

7. Allow water to overflow from bucket until discharge

from hose is bubble free for 30 seconds.

8. Open zone valve to the second zone to be purged,

then close the first. Repeat this step until all zones

have been purged, but always have one zone open.

At completion, open all zone valves.

9. Close hose bib, continue filling the system until

the pressure gauge reads 12 psi. Close fill valve.

(Note - If make-up water line is equipped with

pressure reducing valve, system will automatically

fill to 12 psi.

10. Open isolation valve in boiler supply piping.

11. Remove hose from hose bib.