Lukas Compact Units User Manual

Page 26

26

11.3.4 Replacing hoses (if fitted)

Replace hoses if they are leaky or defective, and if they are older than 10 years. To replace

the hoses, undo the union nuts of the hose connections, remove the hose to be replaced

and replace it with a new hose. Tighten the union nut during the assembly with a torque of

M

A

= 40 Nm.

Also observe the separate operating instructions for the hydraulic hoses.

11.3.3 Direct connection

The screw-in sleeves must be replaced in the event of:

- external damage

- hydraulic fluid continually leaking in connected / unconnected state.

Procedure:

1. Remove the screw-in sleeve from the valve block.

2. Position the new screw-in sleeve and tighten it with a torque of M

A

= 40 Nm.

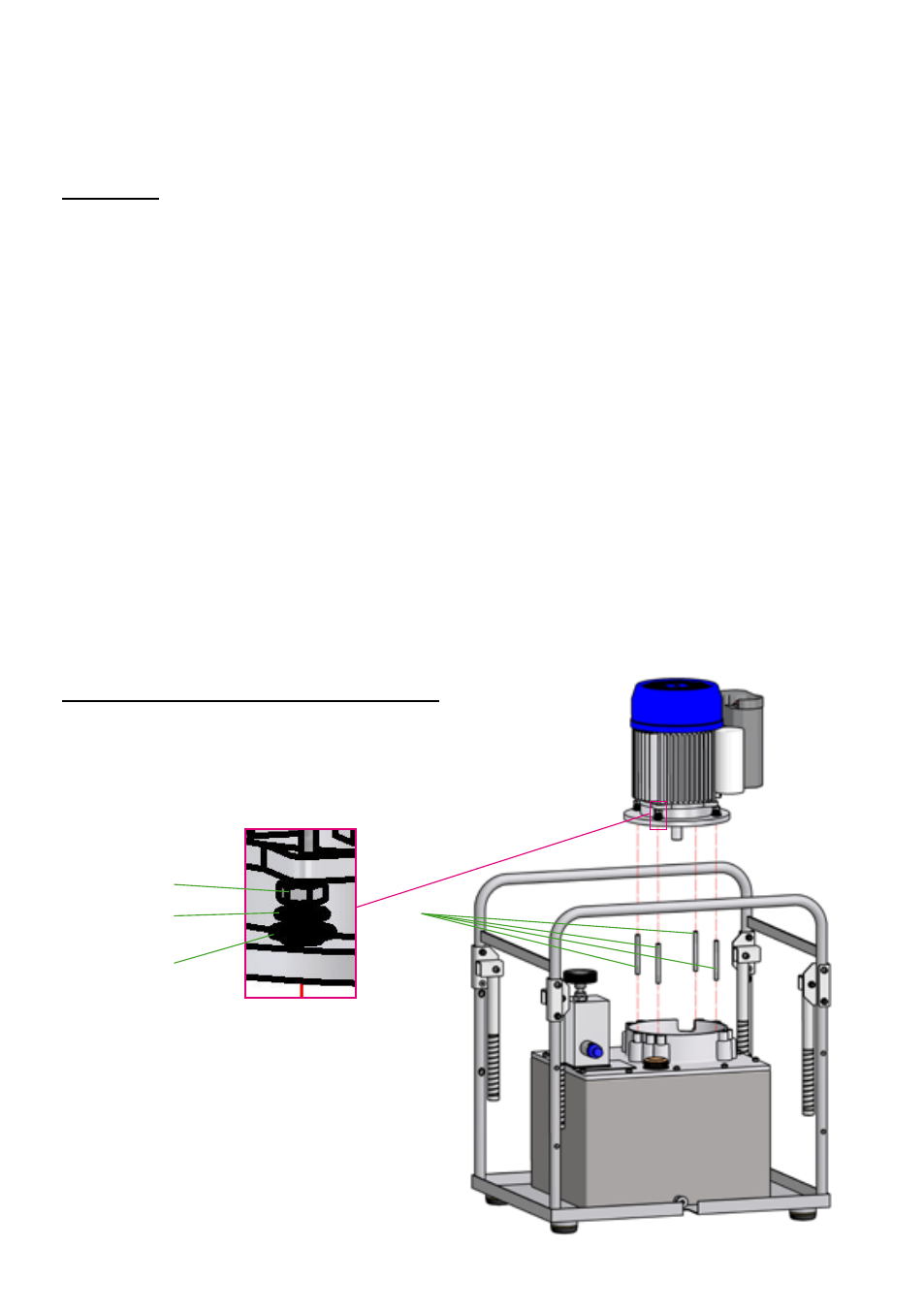

11.3.5 Replacing the engines / motors

Replace the engines / motors if they are defective and direct repair of the valve block by a

dealer or the manufacturer is no longer possible. The engine / motor may only be replaced

with the hydraulic motor switched off. Electric motors must be disconnected from the power

supply.

Engines / motors may only be replaced as a complete component. Empty the fuel tanks of

combustion engines beforehand and make sure that no engine oil escapes when you are

removing the engine.

Procedure for replacing the engine / motor:

1. Loosen securing bolts and nuts “A” on the engine and

remove them along with washers “B” and “C”.

Studs “D” should be exchanged only if they are damaged.

Also observe the relevant spare parts list.

A

B

C

D