Intake air pressure gauge layout option, Low pressure cafs connect (2) – Hale CAFS Attack User Manual

Page 35

35

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

In s talle r In sta llatio n

❑

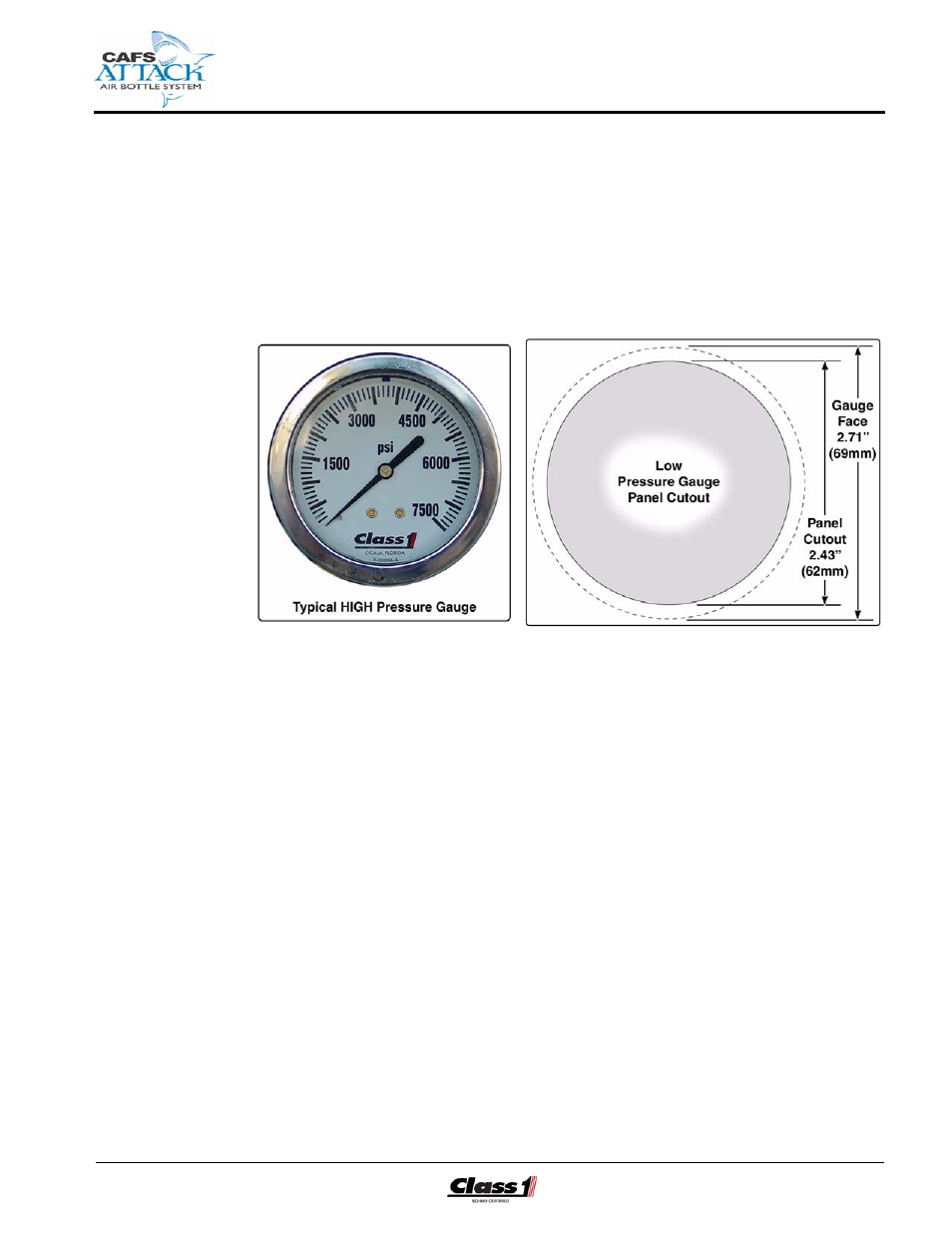

Intake Air Pressure Gauge Layout Option

An “optional” high pressure gauge is available,

Class1 p/n: ??

, to provide

accurate intake air pressure monitoring (up to 7,500 PSI / 517 BAR) during

system operation and cylinder tank refill. (See Figure 4-9: “Typical Intake

Air Pressure Gauge Layout.”)

Figure 4-9: Typical Intake Air Pressure Gauge Layout

The gauge should be mounted in the area of the CAFSAttack operator’s

panel (tank refill connector) and plumbed before the air supply shut-off valve

intake. Provisions must also be made for the pressure transducer.

Also see WARNING ! note beginning on page 32. Use a suitable sealing

compound (for example, Loctite PST) on the fitting threads.

Low Pressure CAFS Connect (2)

A LOW or CAFS air pressure hose line (one each) and injection check

valves (one each) must be plumbed from each electrically-operated shut-off

valve connection to the CAFSAttack discharge manifold air intake port.

(See Figure 4-10: “Typical LOW Pressure CAFS Air Connections,” on page

36.)

1. The installer/builder must provide the necessary plumbing hose and hardware,

i.e., 3/4” (19 mm) fittings, tubing, etc. and make certain they conform to the

maximum CAFS system operating pressure of 150 PSI (10 BAR).