Figure 2-1: cafsattack system overview – Hale CAFS Attack User Manual

Page 16

❑ Description

16

CAFS Air Bottle Installer/Operation Guide

p/n: 029-0020-85-0

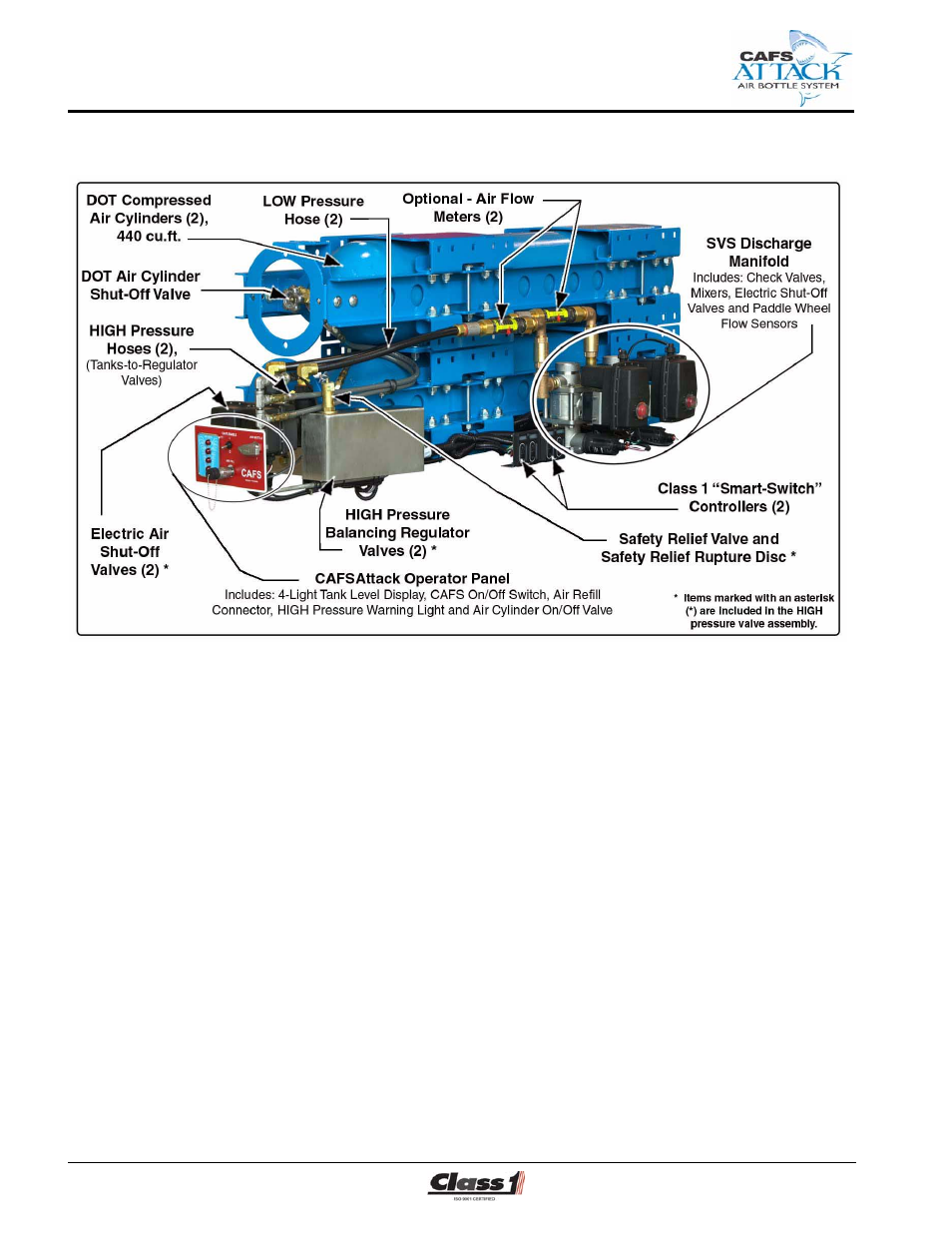

Figure 2-1: CAFSAttack System Overview

❑

HIGH pressure valve assembly - continued

●

Tee-type air filter - used to remove any particulate contaminates from

the system. A multi-layered glass fiber element produces high effi-

ciency silt-control filtration and provides for extended service intervals

and reduced maintenance cost.

A visual pressure indicator enables the operator to read contaminated

build up before the element is plugged, with an automatic reset.

●

Two electrically-controlled open/close air shut-off valves.

●

Pressure safety relief valve, set at 165 PSI (11.4 BAR).

●

Pressure safety relief Rupture Disc, set at 350 PSI (24 BAR).

●

Check valves to ensure separation of water, foam solution, foam con-

centrate and air.

❑

Discharge Manifold

●

Two electrically-controlled shut-off valves, with valve position

indicator.

See separate SVS manual provided (Hale p/n: 209-0020-90-0) for

additional valve information.

●

Mixing chambers.