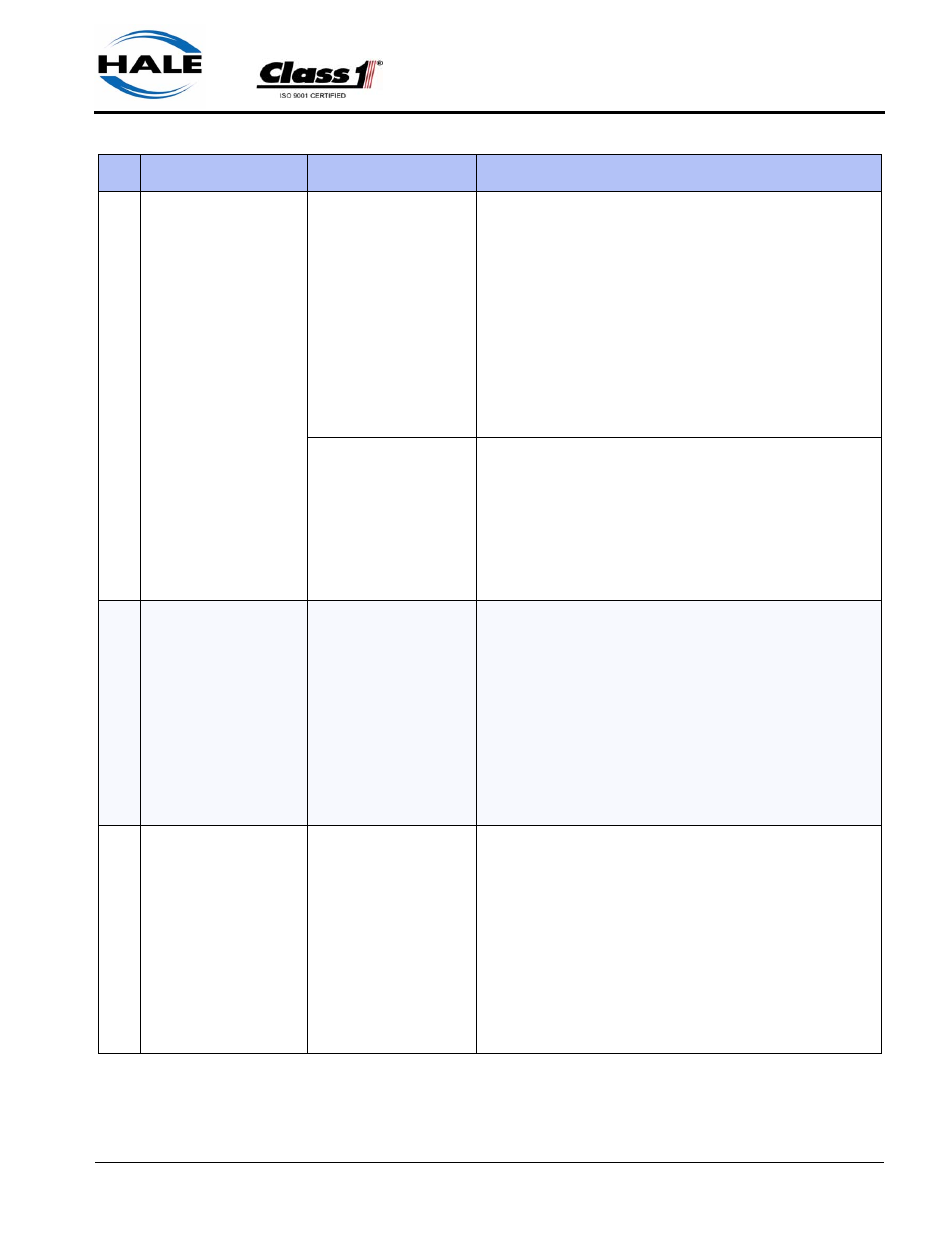

Electric valve fails to operate, Dual tank system option, Table 8-3: troubleshooting table – Class1 EZFill Foam Refill User Manual

Page 42

Service, Maintenance & Troubleshooting

❑

39

EZFill Installer / User Guide, p/n: 029-0020-82-0

3.

System attempts to

FILL and/or FLUSH

but no fluid is

pumped.

KZCO 3-position elec-

tric valve not receiving

power.

●

Power

Check for voltage across power leads to the valve.

●

No voltage

See preceding Step 1 (on page 38) to verify main power

is provided, repair and/or replace accordingly.

●

If voltage is present on valve power leads check for volt-

age on signal line to valve coming from pin 4 of smart-

switch when panel is put into FILL mode.

Note: No voltage will be present in FLUSH mode.

●

If NO voltage is present when switch is in FILL mode,

replace smart switch.

KZCO 3-position elec-

tric valve is internally

defective (binding).

Valve does not shift

between FILL and

FLUSH positions.

●

Binding

Foam residue, left in the valve over time, can casue

binding due to the sticky nature of the foam.

If binding is suspected, the valve must be replaced, or

dismantled and thoroughly cleaned.

Note: It is imperative to thoroughly FLUSH the system

after each use, especially when changing type of foam.

4.

Electric valve fails to

operate.

Valve is obstructed or

defective.

Note: Should the valve

become obstructed (unable to

turn) an internal protection cir-

cuit disables the drive motor

clutch and the valve is no

longer operable via the smart-

switch controller (SPC).

Control of the valve is restored

once power is reset - see next

column.

●

See separate valve manual and check valve for any

obstruction or sluggish operation. Repair accordingly

(disassemble and clean, lubricate, etc.).

●

Check that power is provided to the electric drive motor,

pins #1 and #8 from smart-switch controller. Continuity

test cable harness. Repair and/or replace accordingly.

●

To reset, either reset main power provided to the EZFill

system, or temporarily disconnect the 3-position valve

connector.

●

Once power is restored, check system for proper

operation.

5.

Dual Tank System

Option.

To control filling sepa-

rate foam tanks (A or

B), a dual tank system

adds an additional:

●

Relay (Tank level

switch select)

●

Electric valve

(Tank select 3-

position)

●

Tank level switch

sensor

●

The tank select relay receives voltage from pins #5 and

#6 at the smart-switch connector.

●

The tank select KZCO valve receives power from pin

#6 at the smart-switch connector.

●

The tank level select sensor also receives power from

the relay, pin #87 for Foam Tank "A" and pin # 87A for

Foam Tank "B."

Note: Troubleshooting is the same as the single tank

system, as explained on the preceding pages.

#

Problem

Possible Cause

Remedy

Table 8-3: Troubleshooting Table