Ezfill system does not power on – Class1 EZFill Foam Refill User Manual

Page 41

❑ Service, Maintenance & Troubleshooting

38

EZFill Installer / User Guide, p/n: 029-0020-82-0

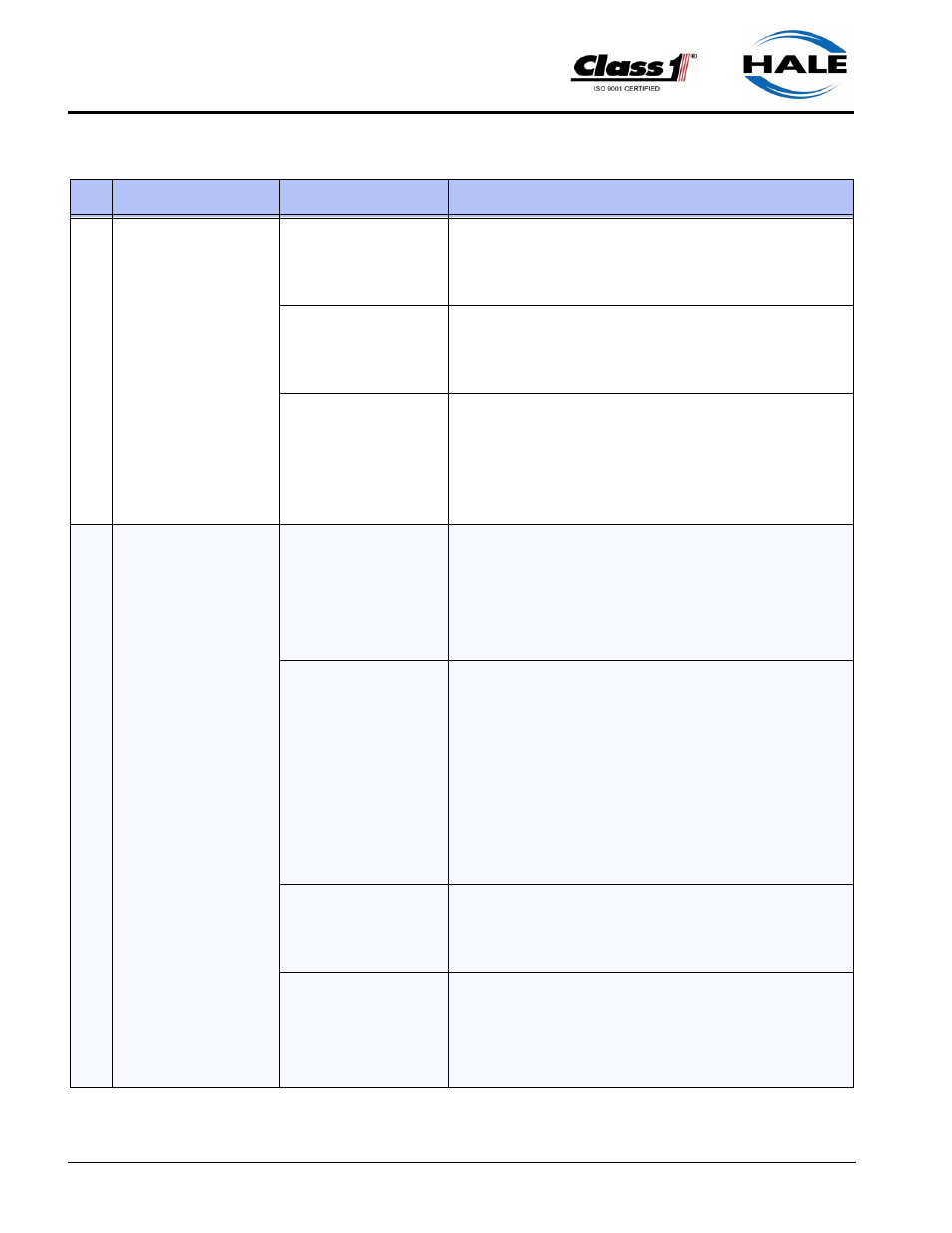

#

Problem

Possible Cause

Remedy

1.

EZFill System does

not power ON.

(Area around switches

Does

NOT backlight.)

Apparatus (operator’s

panel) not receiving

power.

●

Check apparatus operator's panel per manufacturer's

recommendations.

●

See manufacturer's apparatus manual for troubleshoot-

ing procedures.

Blown fuse / disconnect

(between apparatus

and EZFill system).

●

Check and replace with same size fuse. If fuse / dis-

connect blows a second time, system requires further

torubleshooting to determine cause.

●

NEVER insert a larger size fuse.

Main power to EZFill

system not available.

●

Check for main power at pins #1 (+9VDC...+32VDC)

and #8 (vehicle ground) on Smart-Switch. See Figures

6-3 and 6-4 on page 35.

●

If power is available, replace smart-switch

●

If power is not available, continuity test wire harness -

repair and/or replace.

2.

EZFill system is ON,

but CLASS1 logo fails

to light when FILL or

FLUSH buttons are

pressed.

Does pump/motor run

when FILL or FLUSH

buttons are pressed?

●

If motor runs, possible defective LED - repair and/or

replace smart-switch.

●

If motor does NOT run, see headings:

* Defective motor run relay

* Defective tank FILL sensor

* Bad motor

Defective motor relay

(Single Tank).

Note: For a Dual Tank system,

see Step 4 on page 38.

●

Check for main voltage (+9VDC...+32VDC) at pin #30

on relay. See Figure 6-1 on page 33.

No voltage - see preceding Step 1 to verify main power

is provided, repair and/or replace accordingly.

●

If voltage is OK, check for voltage from smart-switch at

pin #85 on relay. See Figure 6-1 on page 33. No volt-

age - replace smart-switch.

●

Check for voltage at pin # 87 on relay. Low or odd volt-

age indicates possible motor stall leading to possible

blown fuse / disconnect. No voltage indictaes defective

relay - replace.

Defective motor.

●

Check for voltage across motor contacts. Low or odd

voltage indicates possible motor stall leading to possi-

ble blown fuse / disconnect.

●

Repair and/or replace motor.

Defective FULL tank

level sensor.

Note: A defective sensor can

prevent pump motor operation

by providing a constant tank

FULL signal.

●

Using an ohmmeter, check for current across sensor

switch leads.

●

Low ohm reading is present when switch is activated

Zero (0) reading when switch is released, indicating a

FILL requirement.

Table 8-3: Troubleshooting Table