Appendix a, Appendix b, Air conditioner & heat pump with puron – Bryant 569J User Manual

Page 48: Quick reference guide, Wiring diagram list

48

APPENDIX A

Air Conditioner & Heat Pump with PURON

®

— Quick Reference Guide

S

Puron

®

(R-410A) refrigerant operates at 50 percent to

70 percent higher pressures than R-22. Be sure that

servicing equipment and replacement components are

designed to operate with Puron®.

S

Puron® refrigerant cylinders are rose colored.

S

Recovery cylinder service pressure rating must be 400

psig, DOT 4BA400 or DOT BW400.

S

Puron® systems should be charged with liquid

refrigerant. Use a commercial type metering device in

the manifold hose when charging into suction line with

compressor operating.

S

Manifold sets should be 700 psig high side and 180 psig

low side with 550 psig low-side retard.

S

Use hoses with 700 psig service pressure rating.

S

Leak detectors should be designed to detect HFC

refrigerant.

S

Puron®, as with other HFCs, is only compatible with

POE oils.

S

Vacuum pumps will not remove moisture from oil.

S

Use only factory specified liquid-line filter driers with

rated working pressures greater than 600 psig.

S

Do not install a suction-line filter drier in liquid-line.

S

POE oils absorb moisture rapidly. Do not expose oil to

atmosphere.

S

POE oils may cause damage to certain plastics and

roofing materials.

S

Wrap all filter driers and service valves with wet cloth

when brazing.

S

A factory approved, liquid-line filter drier is required on

every unit.

S

Do not use an R-22 TXV.

S

If indoor unit is equipped with a TXV, it must be

changed to a Puron

®

TXV.

S

Never open system to atmosphere while it is under a

vacuum.

S

When system must be opened for service, recover

refrigerant, break vacuum with dry nitrogen before

opening system.

S

Always replace filter drier after opening system for

service.

S

Do not vent Puron

®

into the atmosphere.

S

Do not use capillary tube coils.

S

Observe all warnings, cautions, and bold text.

S

All Puron

®

heat pumps must have indoor TXV.

S

Do not leave Puron

®

suction line driers in place for

more than 72 hours.

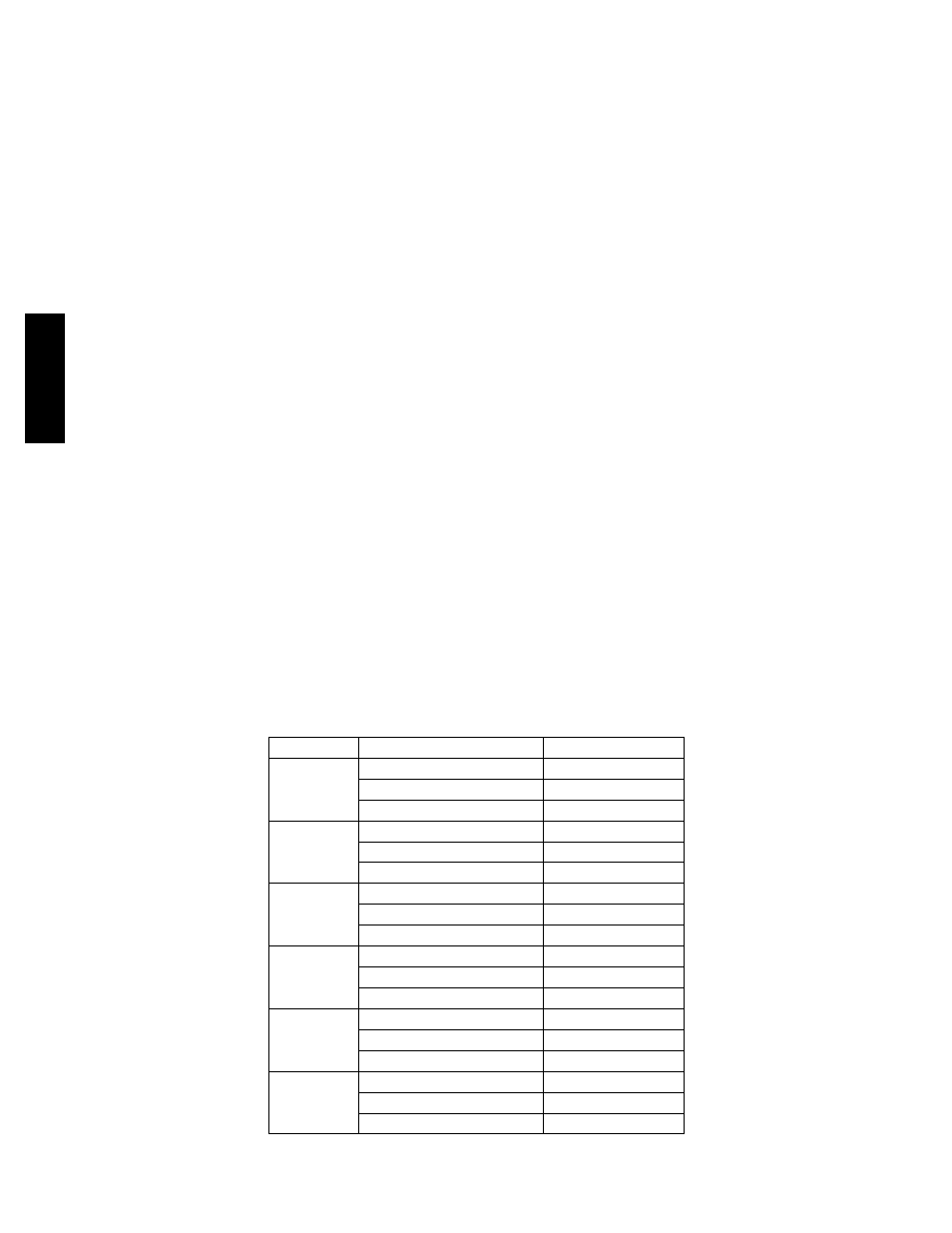

APPENDIX B

Wiring Diagram List

569J* Size

Electrical Characteristics

Diagram Number

07A/B

208/230---3---60

38AU500320

460---3---60

38AU500432

575---3---60

38AU500337

08A/B

208/230---3---60

38AU500320

460---3---60

38AU500432

575---3---60

38AU500337

12A/B

208/230---3---60

38AU500320

460---3---60

38AU500432

575---3---60

38AU500337

14A/B

208/230---3---60

38AU500107

460---3---60

38AU500432

575---3---60

38AU500337

12D/E

208/230---3---60

38AU500562

460---3---60

38AU500563

575---3---60

38AU500564

14D/E

208/230---3---60

38AU500562

460---3---60

38AU500563

575---3---60

38AU500564

569J