Seat core – Bryant 569J User Manual

Page 38

38

Liquid Line Filter Drier —

The factory-provided filter drier is specifically designed to

operate with Puron

®

. Replace the filter drier with

factory-authorized components only with a filter drier

with desiccant made from 100% molecular sieve grade

XH-11. Filter drier must be replaced whenever the

refrigerant system is opened.

When removing a filter drier, use a tubing cutter to cut the

drier from the system. Do not unsweat a filter drier from

the system. Heat from unsweating will release moisture

and contaminants from drier into system.

Field Refrigerant Access Ports —

Field service access to refrigerant pressures is through the

access ports located at the service valves (see Figs 38 and

40). These ports are

1

/

4

-in SAE Flare couplings with

Schrader check valves and service caps. Use these ports to

admit nitrogen to the field tubing during brazing, to

evacuate the tubing and evaporator coil, to admit initial

refrigerant charge into the low-side of the system and

when checking and adjusting the system refrigerant

charge. When service activities are completed, ensure the

service caps are in place and secure; check for leaks. If

the Schrader check valve must be removed and

re-installed, tighten to 2-3 in-lbs (23-34 N-cm).

Factory High-Flow Access Ports —

There are two additional access ports in the system - on

the suction tube between the compressor and the suction

service valve and on the liquid tube near the liquid service

valve (see Figs 39 and 41). These are brass fittings with

black plastic caps. The hose connection fittings are

standard

1

/

4

-in SAE Male Flare couplings.

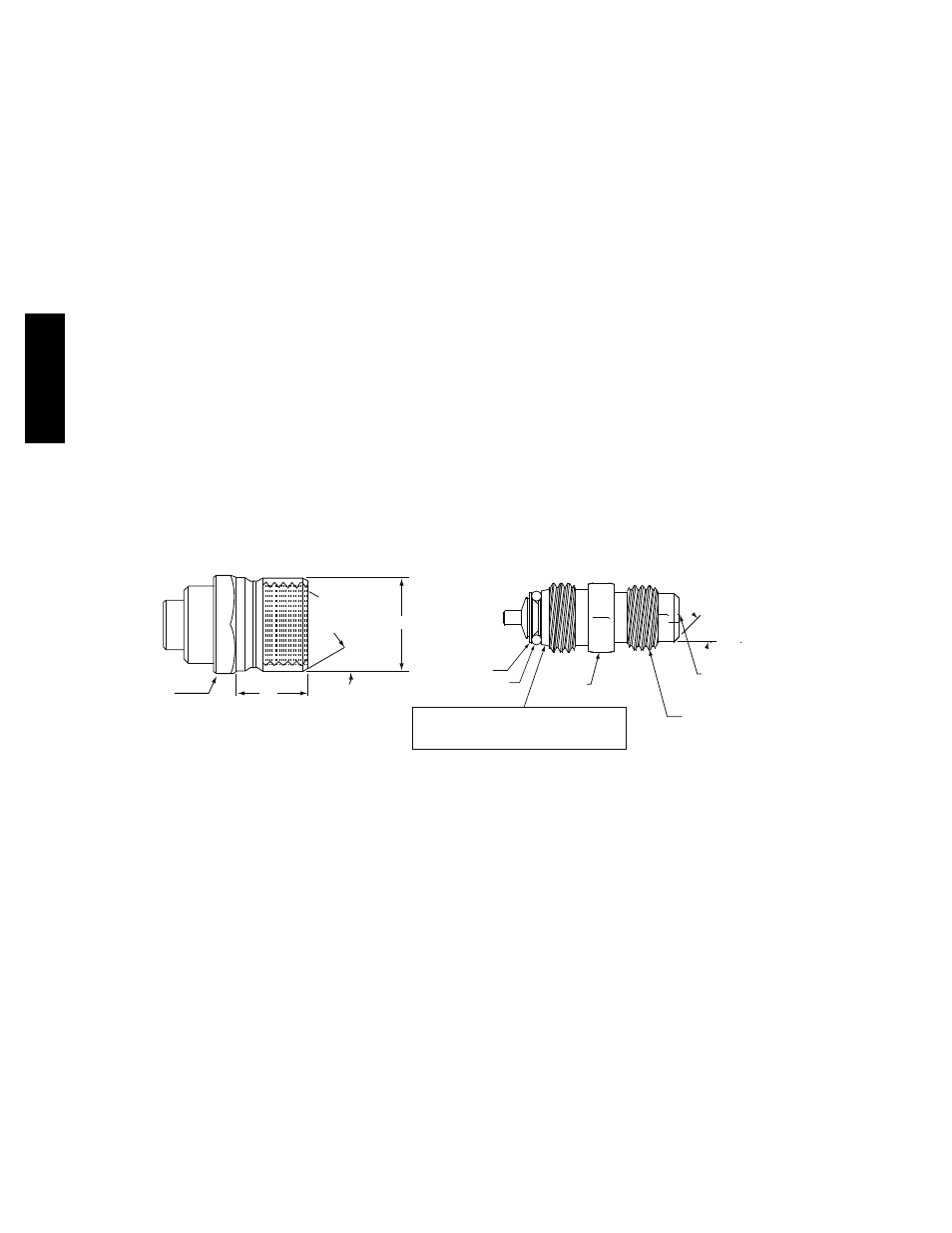

The brass fittings are two-piece High Flow valves, with a

receptacle base brazed to the tubing and an integral

spring-closed check valve core screwed into the base. (See

Fig. 35) This check valve is permanently assembled into

this core body and cannot be serviced separately; replace

the entire core body if necessary. Service tools are

available from RCD that allow the replacement of the

check valve core without having to recover the entire

system refrigerant charge. Apply compressor refrigerant

oil to the check valve core’s bottom o-ring. Install the

fitting body with 96 ±-10 in-lbs (1085 ±23 N-cm) of

torque; do not overtighten.

1/2-20 UNF RH

30°

0.596

.47

5/8” HEX

SEAT

CORE

WASHER

DEPRESSOR PER ARI 720

+.01/-.035

FROM FACE OF BODY

7/16-20 UNF RH

O-RING

45°

1/2" HEX

This surface provides a metal to metal seal when

torqued into the seat. Appropriate handling is

required to not scratch or dent the surface.

(Part No. EC39EZ067)

C08453

Fig. 35 -- CoreMax Access Port Assembly

569J