Bryant 569J User Manual

Page 13

13

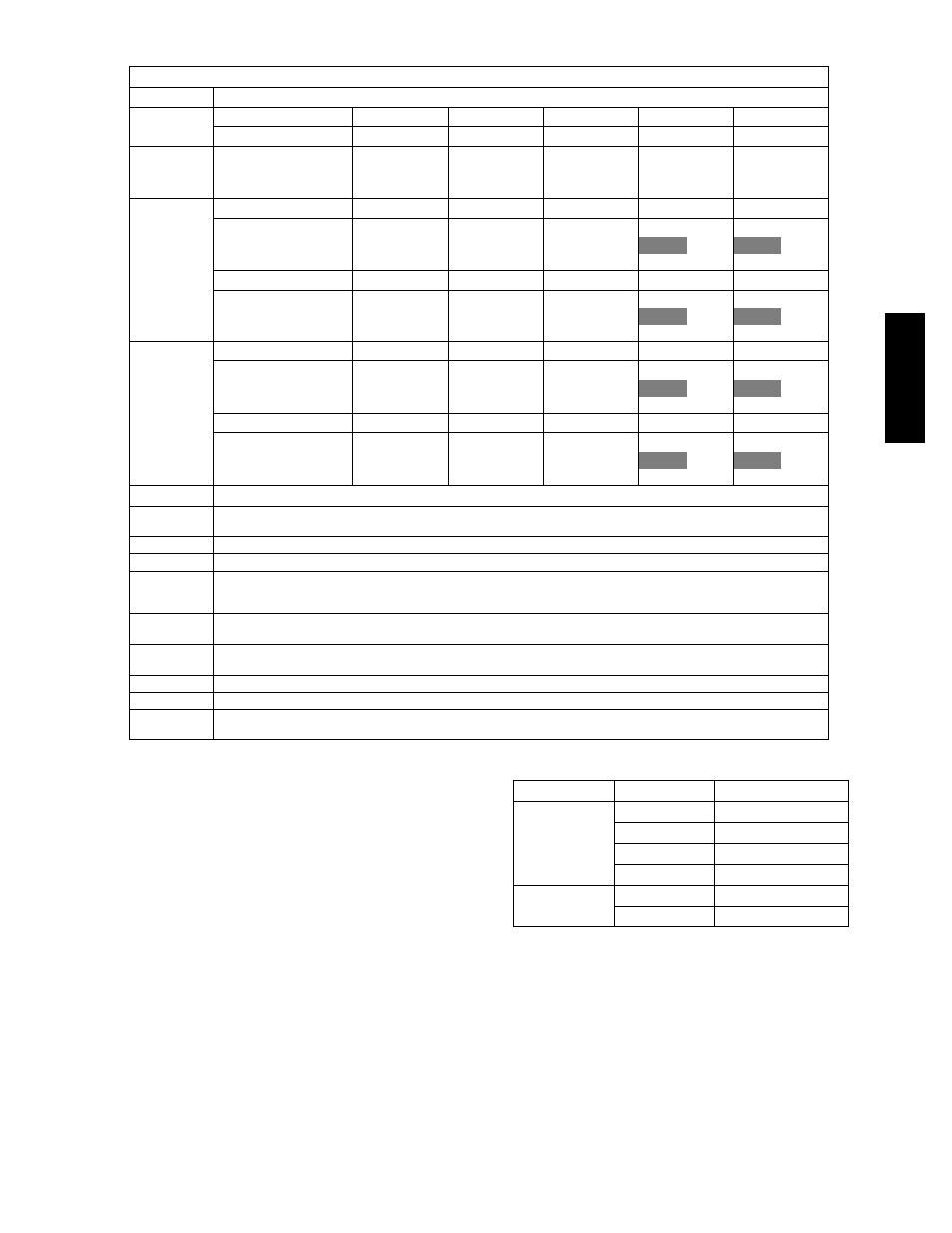

Table 6 – 569J*12-14D/E Piping Recommendations (Two-Circuit Unit)

NOTE: 569J***D/E requires TWO sets of refrigeration piping

R---410A

Equivalent Length

Ft

0---38

38---75

75---113

113---150

150---188

m

0---12

12---23

23---34

34---46

46---57

Model

Linear Length

Ft

0---25

25---50

50---75

75---100

100---125

m

0---8

8---15

15---23

23---30

30---38

569J*12D/E Liquid Line

3

/

8

3

/

8

3

/

8

1

/

2

3

/

8

1

/

2

3

/

8

1

/

2

Max Lift (ft)

Novation

25

50

28

75

DNU

100

DNU

99

RTPF

25

50

75

NR

83

100

62

125

Suction Line

7

/

8

7

/

8

1

1

/

8

1

1

/

8

1

1

/

8

Charge (lbs) (ea circuit)

Novation

7.1

8.1

9.6

11.9

DNU

13.8

DNU

15.8

RTPF

13.3

14.3

15.8

NR

16.9

20.0

18.1

22.0

569J*14D/E Liquid Line

3

/

8

3

/

8

3

/

8

1

/

2

3

/

8

1

/

2

3

/

8

1

/

2

Max Lift (ft)

Novation

25

50

48

75

DNU

100

DNU

122

RTPF

25

50

75

NR

54

100

45

125

Suction Line

7

/

8

7

/

8

1

1

/

8

1

1

/

8

1

1

/

8

Charge (lbs) (ea circuit)

Novation

9.7

10.7

14.5

DNU

16.4

DNU

18.4

RTPF

23.0

24.0

27.8

NR

26.6

29.7

27.8

31.7

Legend:

Equivalent

Length

Equivalent tubing length, including effects of refrigeration specialties devices

Linear Length

Linear tubing length, feet

Liquid Line

Tubing size, inches OD.

Max Lift

Maximum liquid lift (indoor unit ABOVE outdoor unit only), at maximum permitted liquid line pressure drop

S

Linear Length Less than 75 ft (23 m): Minimum 2.0° F subcooling entering TXV

S

Linear Length Greater than 75 ft (23m): Minimum 0.5° F subcooling entering TXV

Suction Line

Tube size, inches OD

See highlighted: Do not use with RTPF coil model

Charge

Charge Quantity, lbs. Calculated for both liquid line sizes (where applicable), but only with larger suction line size (where

applicable)

DNU

Do Not Use (pressure drop exceeds available subcooling in this model)

NR

Not Recommended (use smaller liquid tube size)

NOTE:

For applications with equivalent length greater than 188 ft (57 m) and/0r linear length greater than 125 ft (38 m), contact

your local Bryant representative.

Suction Riser —

A suction riser condition exists when the outdoor unit is

located above the indoor (evaporator) unit and suction vapor

must flow vertically up to return to the compressor. Oil

return is a concern when the suction tube size is too large to

produce the minimum refrigerant velocity to ensure oil

return at minimum load conditions.

Check Table 7 for maximum suction tube size for 569J units

at minimum load conditions. Consider suction speed riser

(reduced tube size for vertical segment only) or double

suction riser arrangement if the proposed suction tube size

does not provide necessary minimum flowrates for this riser.

Vertical Separation (outdoor unit above indoor unit) –

Vertical elevation difference of 200 ft (60 m) is permitted

when the outdoor unit (569J***A/B or 569J***D/E) is

located above the indoor unit.

Insulate Suction Lines —

Apply closed-cell tubular insulation to all suction lines

between evaporator coil connection and 569J unit’s

suction service valve.

Table 7 –

569J Maximum Suction Pipe Size

Model:

Unit Size

Maximum Tube Size

569J***A/B

07

1

3

/

8

08

1

5

/

8

12

1

5

/

8

14

2

1

/

8

569J***D/E

12

1

3

/

8

14

1

5

/

8

Hot Gas Bypass —

Hot gas bypass, if used, should be introduced before the

evaporator. (A bypass route that also bypasses the evaporator

circuit may lead to oil trapping in the evaporator circuit

during low load conditions and then to oil slugging as

evaporator load increases.) Model 569J units do not include

a hot gas stub connection; a tee must be field-supplied and

installed in the compressor discharge line. Run the hot gas

line between outdoor unit and evaporator coil inlet. Install an

Auxiliary Side Connector at the evaporator between TXV

and distributor (follow instructions for the side connector

part). Insulate the hot gas line.

569J