569j – Bryant 569J User Manual

Page 15

15

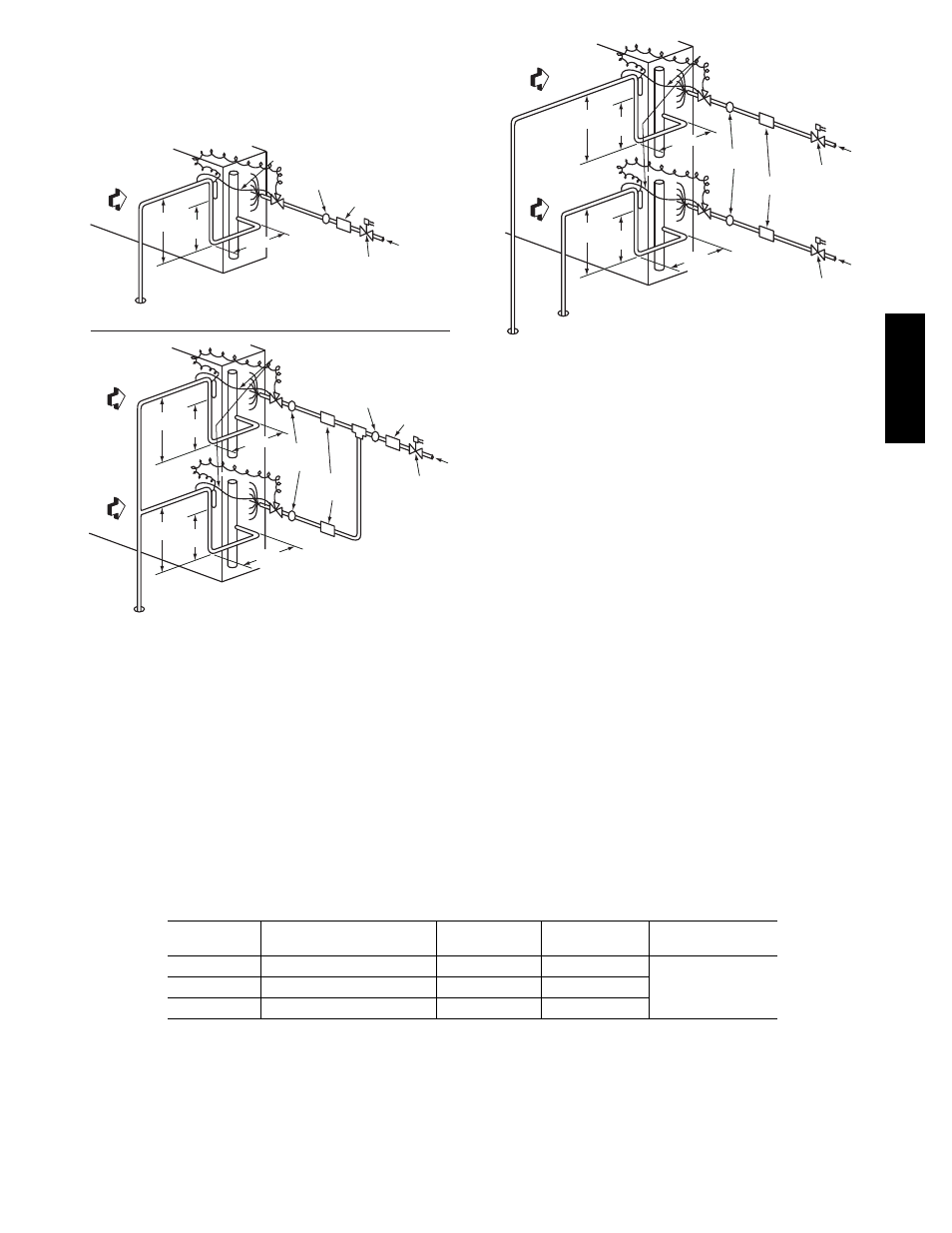

Installation of liquid line moisture indicating sightglass in

each circuit is recommended. Locate the sightglass(es)

between the outlet of the filter drier and the TXV inlet.

Refer to Table 9 for recommendations on refrigeration

specialties.

INDOOR

COIL CKT 2

AIRFLOW

INDOOR

COIL CKT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

SIGHT

GLASSES

B LOCATION

TXV

CKT 2

FILTER DRIER

A LOCATION

FILTER

DRIERS

B LOCATION

FLOW

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

Single Circuit Coil Piping Configuration

For single compressor condensing units

Dual Circuit Coil Piping Configuration

For single compressor condensing units

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

INDOOR

COIL CKT

AIRFLOW

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT GLASS

A LOCATION

TXV

FILTER DRIER

A LOCATION

LIQUID LINE

SOLENOID

VALVE

FLOW

LIQUID LINE

SOLENOID

VALVE

C10202

Fig. 7 -- Location of Sight Glass(es) and Filter Driers

Typical 569J***A/B Systems

AIRFLOW

SUCTION

CIRCUIT 2

SUCTION

CIRCUIT 1

AIRFLOW

15 DIAMS

MIN

10

DIAMS

8 DIAMS

MIN

TXV

SENSING

BULB

EQUALIZER LINE

SIGHT

GLASSES

TXV

CKT 2

FILTER

DRIERS

LIQUID LINE

SOLENOID VALVE

CIRCUIT 2

FLOW

LIQUID LINE

SOLENOID VALVE

CIRCUIT 1

FLOW

TXV

SENSING

BULB

TXV

CKT 1

8 DIAMS

MIN

15 DIAMS

MIN

10

DIAMS

Dual Circuit Coil Piping Configuration

For two circuit condensing units

C10072

Fig. 8 -- Location of Sight Glasses and Filter Driers

Typical 569J***D/E Systems

In some applications, depending on space and

convenience requirements, it may be desirable to install 2

filter driers and sight glasses in a single circuit

application. One filter drier and sight glass may be

installed at A locations (see Fig. 7) or 2 filter driers and

sight glasses may be installed at B locations (see Figs. 7

and 8).

Select the filter drier for maximum unit capacity and

minimum pressure drop. Complete the refrigerant piping

from the indoor unit to the outdoor unit before opening

the liquid and suction lines at the outdoor unit.

Install Liquid Line Solenoid Valve —

It is recommended that a solenoid valve be placed in the

main liquid line (see Figs. 7 and 8) between the condensing

unit and the evaporator coil. Locate the solenoid valve at the

outlet end of the liquid line, near the evaporator coil

connections, with flow direction arrow pointed at the

evaporator coil. Refer to Table 9. (A liquid line solenoid

valve is required when the liquid line length exceeds 75 ft

[23 m].) This valve prevents refrigerant migration (which

causes oil dilution) to the compressor during the off cycle, at

low outdoor ambient temperatures.

Table 9 – Refrigerant Specialties Part Numbers

LIQUID LINE

SIZE (in.)

LIQUID LINE

SOLENOID VALVE (LLSV)

LLSV

COIL

SIGHT

GLASS

FILTER

DRIER

3

/

8

EF680033

EF680037

KM680008

provided with unit

see Table 8

1

/

2

EF680035

EF680037

KM680004

5

/

8

EF680036

EF680037

KM680005

569J***D/E units require TWO sets of parts.

569J