Bryant 569J User Manual

Page 14

14

Refer to Hot Gas Bypass line sizing tables for appropriate

size. Contact your Bryant representative for a copy of

these tables.

569J***D/E: Generally only one hot gas bypass system

will be applied on a two-circuit unit. Connect the hot gas

bypass system to Circuit 1 (first-on/last-off, connected to

the evaporator coil’s bottom circuit).

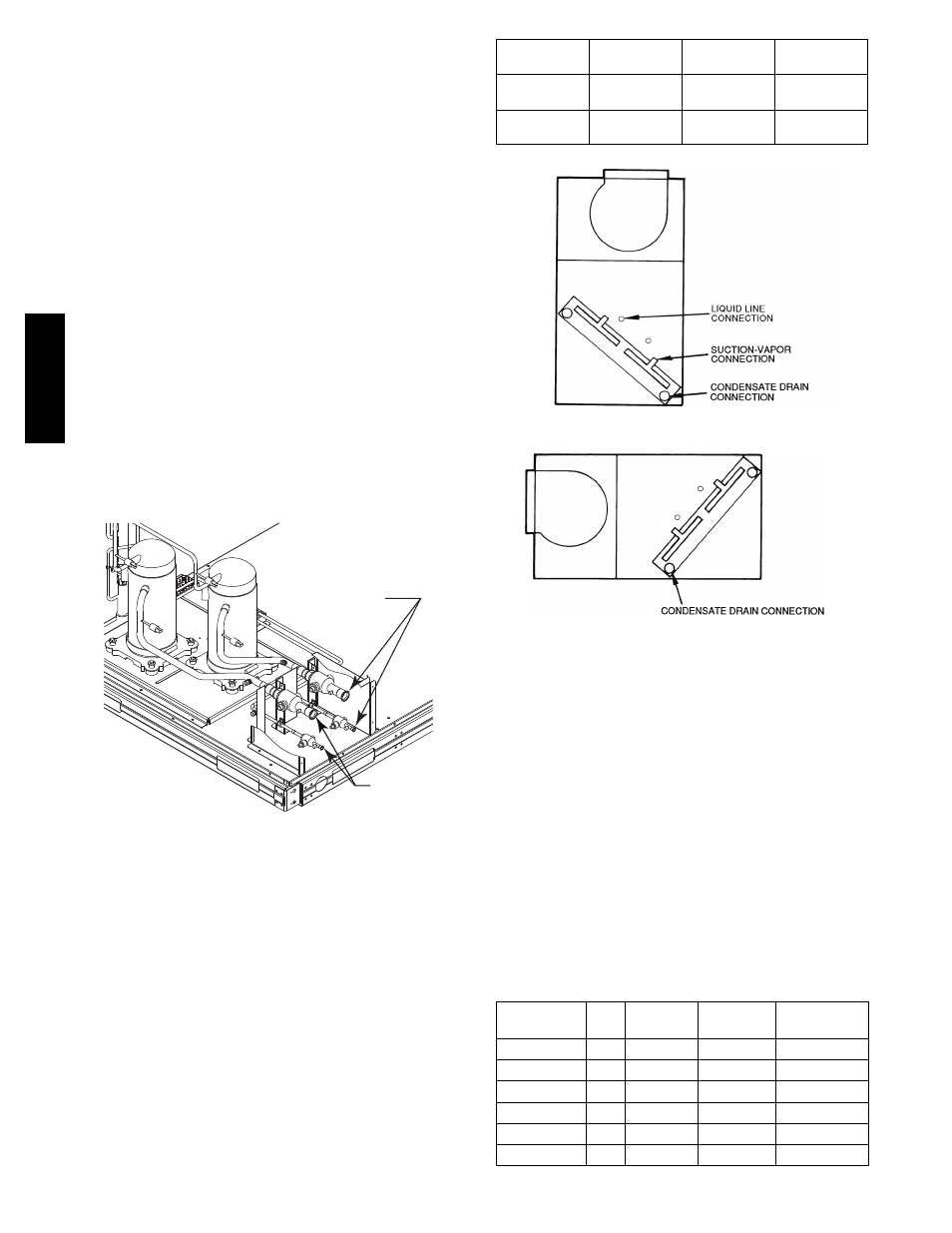

569J***D/E Piping Connections —

The 569J***D/E unit’s two circuits are designated Circuit 1

and Circuit 2. Circuit 1 is controlled by the thermostat’s Y1

(or TC1) contact and will be the first circuit on and last

circuit off. Circuit 2 is controlled by the thermostat’s Y2 (or

TC2) contact and this circuit is always the “lag” circuit.

See Fig. 5 for location of Circuit 1 and Circuit 2 service

valves and field piping connections. Circuit 1 is on the

right-hand side of the service valve compartment; Circuit 2

is on the left.

When a single piece evaporator coil with two separate

circuits is connected to a 569J***D/E, the lower coil circuit

should be connected to the 569J***D/E unit’s Circuit 1 so

that the evaporator’s lower coil segment is first-on/last-off

(to avoid re-evaporation of condensate on dry lower coil

segments).

Circuit 1

Connections

Circuit 2

Connections

CKT

2

CKT

1

C10912

Fig. 5 -- 569J***D/E Service Valve Locations

Plan the Circuit 1 and Circuit 2 tubing segments carefully,

mark each segment and check constantly as piping systems

are assembled to avoid piping errors.

569J***D/E

unit

cannot

be

field-piped

as

a

single-circuit/tandem system.

Connecting 524J to 569J***D/E: The 524J fan coil in sizes

12, 14 and 16 is a face-split coil design that also has its

circuits designated as 1 and 2. See Fig. 6. Note that the

lower coil segment changes as the arrangement of the 524J

changes. In a vertical arrangement, the 524J’s lower coil

segment is segment 2; this segment should be connected to

the 569J***D/E’s Circuit 1. In a horizontal arrangement, the

524J’s lower segment is now segment 1; this segment should

be connected to the 569J***D/E’s Circuit 1.

Note that refrigerant suction piping should be insulated.

524J

Arrangement

Cooling

Stage

524J Coil

Segment

Connect to

569J***D/E

Vertical

Y1

Y2

2

1

Circuit 1

Circuit 2

Horizontal

Y1

Y2

1

2

Circuit 1

Circuit 2

FIRST ON/LAST OFF = 2

VERTI CAL I NSTALLATI ON

FIRST ON/LAST OF F = 1

HORIZONTAL INSTALLATIO N

1

2

2

1

C10071

Fig. 6 -- Typical Evaporator Coil Connections (524J)

Install Filter Drier(s) and Moisture Indicator(s) —

Every unit MUST have a filter drier in the liquid line.

569J***D/E models require two filter driers (one in each

liquid line). Locate the filter drier(s) at the indoor unit,

close to the evaporator coil’s thermal expansion valve

(TXV) inlets.

569J

units

include

one

(569J***A/B)

or

two

(569J***D/E) Puron-duty filter drier(s), shipped in cartons

attached to the unit basepan. Remove the filter drier(s)

and prepare to install in the liquid line(s) at the evaporator

coil. Do not remove connection fitting plugs until ready to

connect and braze the filter drier into the liquid line

position.

Table 8 – Puron-duty Filter Drier(s)

Model-Size

Qty

Liquid

Line OD

Desiccant

Volume

Part

Number Ref

569J*07A/B

1

3

/

8

-in

8 cu. in.

KH43LG091

569J*08A/B

1

1

/

2

-in

16 cu. in.

KH43LG085

569J*12A/B

1

1

/

2

-in

16 cu. in.

KH43LG085

569J*14A/B

1

5

/

8

-in

16 cu. in.

KH43LG086

569J*12D/E

2

3

/

8

-in

8 cu. in.

KH43LG091

569J*14D/E

2

1

/

2

-in

16 cu. in.

KH43LG085

569J