Bryant 582A User Manual

Page 9

7. Pressure-test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

NOTE:

Pressure test the gas supply system after the gas supply

piping is connected to the gas valve. The supply piping must be

disconnected from the gas valve during the testing of the piping

systems when test pressure is in excess of 0.5 psig. Pressure test

the gas supply piping system at pressures equal to or less than 0.5

psig. The unit heating section must be isolated from the gas piping

system by closing the external main manual shutoff valve and

slightly opening the ground-joint union.

CAUTION:

Unstable operation may occur when the gas

valve and manifold assembly are forced out of position

while connecting improperly-routed rigid gas piping to

the gas valve. Use a backup wrench when making

connection to avoid strain on, or distortion of, the gas

control piping.

CAUTION:

If a flexible conductor is required or al-

lowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and shall extend a

minimum of 2 in. outside the unit casing.

WARNING:

Never use a match or other open flame

when checking for gas leaks. Never purge gas line into

combustion chamber. Failure to follow this warning

could result in an explosion causing serious injury or

death.

TABLE 2—PHYSICAL DATA—UNIT 583A

UNIT SIZE 583A

024040

024060

030040

030060

036060

036090

042060

042090

NOMINAL CAPACITY (ton)

2

2

2½

2½

3

3

3½

3½

OPERATING WEIGHT (lb.)

290

290

313

313

321

321

382

382

COMPRESSORS

Quantity

Scroll

1

REFRIGERANT (R-22)

Quantity (lb.)

3.7

3.7

4.4

4.4

5.2

5.2

6.4

6.4

REFRIGERANT METERING DEVICE

Orifice ID (in.)

.034

.034

.030

.030

.032

.032

.034

.034

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

1...17

10.8

1...17

10.8

1...17

12.7

1...17

12.7

2...17

9.1

2...17

9.1

2...17

12.3

2...17

12.3

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

2350

22

1/8 (825)

3300

22

1/8 (825)

3300

22

1/8 (825)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

3...15

3.1

3...15

3.1

3...15

3.1

3...15

3.1

3...15

3.7

3...15

3.7

3...15

4.7

3...15

4.7

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

800

10 X 10

1/4 (1075)

800

10 X 10

1/4 (1075)

1000

10 X 10

1/4 (1075)

1000

10 X 10

1/4 (1075)

1200

11 X 10

1/2 (1075)

1200

11 X 10

1/2 (1075)

1400

11 X 10

3/4 (1075)

1400

11 X 10

3/4 (1075)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

2...44

2...50

2...38

2...46

2...44

2...50

2...38

2...46

2...38

2...46

3...38

3...46

2...38

2...46

3...38

3...46

RETURN-AIR FILTERS (in.)†

Throwaway

20 X 20

20 X 20

20 X 20

20 X 20

20 X 24

20 X 24

24 X 30

24 X 30

* Based on altitude of 0 to 2000 ft.

† Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300

ft/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

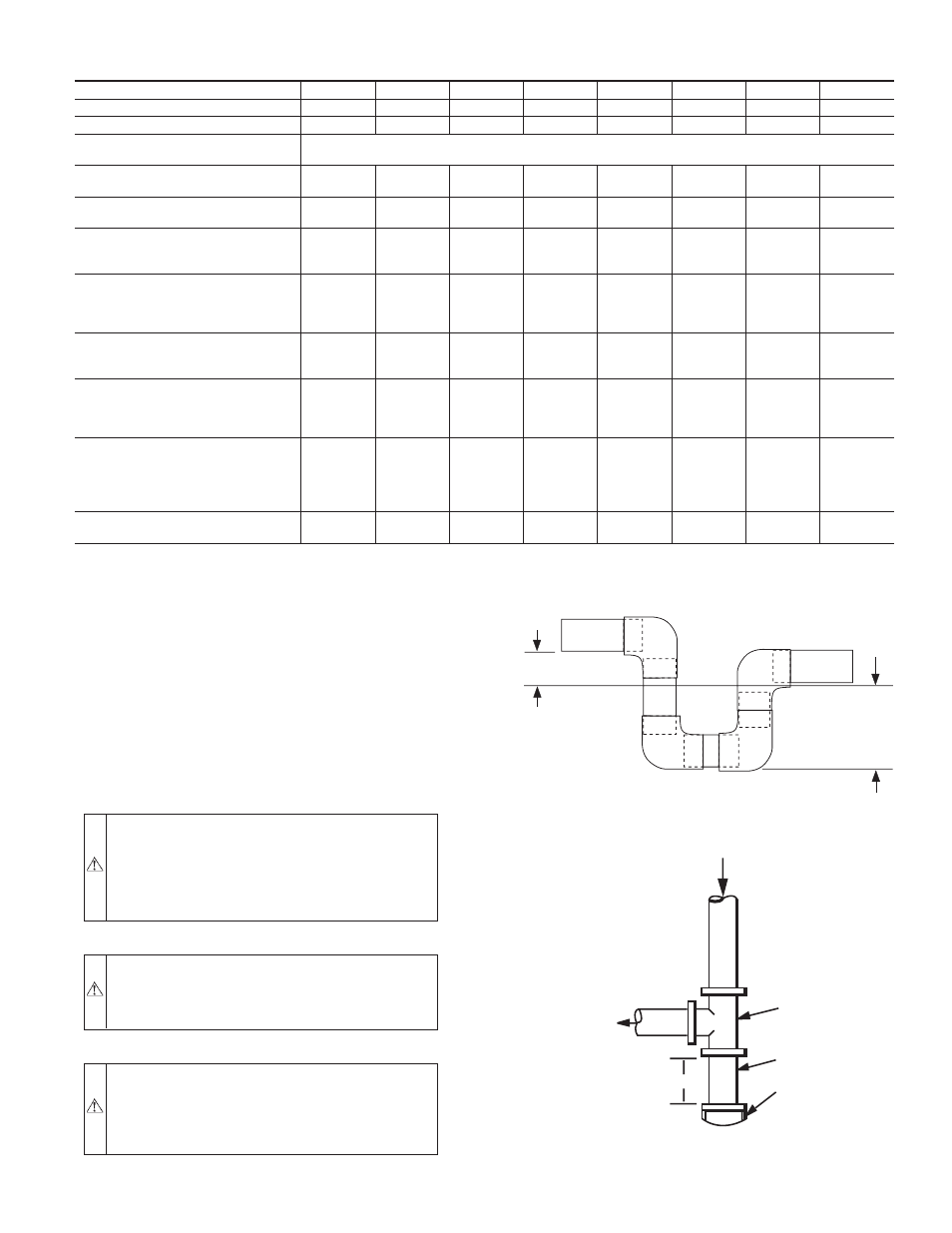

Fig. 8—Condensate Trap

C00009

TRAP

OUTLET

2" min.

1" min.

Fig. 9—Sediment Trap

C99020

OUT

TEE

NIPPLE

CAP

IN

3˝ MIN

—9—