Bryant 582A User Manual

Page 8

NOTE:

Low NO

x

requirements apply only to natural gas instal-

lations.

CAUTION:

The venting system is designed to ensure

proper venting. The flue hood assembly must be installed

as indicated in this section of the unit installation instruc-

tions.

Install the flue hood as follows:

1. This installation must conform with local building codes

and with the National Fuel Gas Code (NFGC), ANSI

Z223.1 (in Canada, CAN/CGA B149.1, and B149.2) or

NFPA (National Fire Protection Association) latest revi-

sion. Refer to Provincial and local plumbing or wastewater

codes and other applicable local codes.

2. Remove flue hood from shipping location (inside the

blower compartment). Place vent cap assembly over flue

panel. Orient screw holes in vent cap with holes in the flue

panel.

3. Secure flue hood to flue panel by inserting a single screw on

the right side and the left side of the hood.

VIII.

INSTALL GAS PIPING

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the 1/2-in. FPT

gas inlet on the manual shutoff or gas valve.

Install a gas supply line that runs to the heating section. Refer to

Table 3 and the NFGC for gas pipe sizing. Do not use cast-iron

pipe. It is recommended that a black iron pipe is used. Check the

local utility for recommendations concerning existing lines. Size

gas supply piping for 0.5 in. wg maximum pressure drop. Never

use pipe smaller than the 1/2-in. FPT gas inlet on the unit gas

valve.

For natural gas applications, the gas pressure at unit gas connection

must not be less than 4.0 in. wg or greater than 13 in. wg while the

unit is operating. For propane applications, the gas pressure must

not be less than 7.0 in. wg or greater than 13 in. wg at the unit

connection.

An 1/8-in. NPT plugged tapping, accessible for test gage connec-

tion, must be installed immediately upstream of the gas supply

connection to the gas valve.

When installing the gas supply line, observe local codes pertaining

to gas pipe installations. Refer to the NFGC ANSI Z223.1-1988

NFPA latest edition (in Canada, CAN/CGA B149.1, (2)-M86). In

the absence of local building codes, adhere to the following

pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe 1/4 in.

in every 15 ft to prevent traps. Grade all horizontal runs

downward to risers. Use risers to connect to heating section

and to meter.

2. Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate straps,

hangers, etc. Use a minimum of one hanger every 6 ft. For

pipe sizes larger than 1/2 in., follow recommendations of

national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national codes.

Never use Teflon tape.

4. Install sediment trap in riser leading to heating section (See

Fig. 9). This drip leg functions as a trap for dirt and

condensate.

5. Install an accessible, external, manual main shutoff valve in

gas supply pipe within 6 ft of heating section.

6. Install ground-joint union close to heating section between

unit manual shutoff and external manual main shut-off

valve.

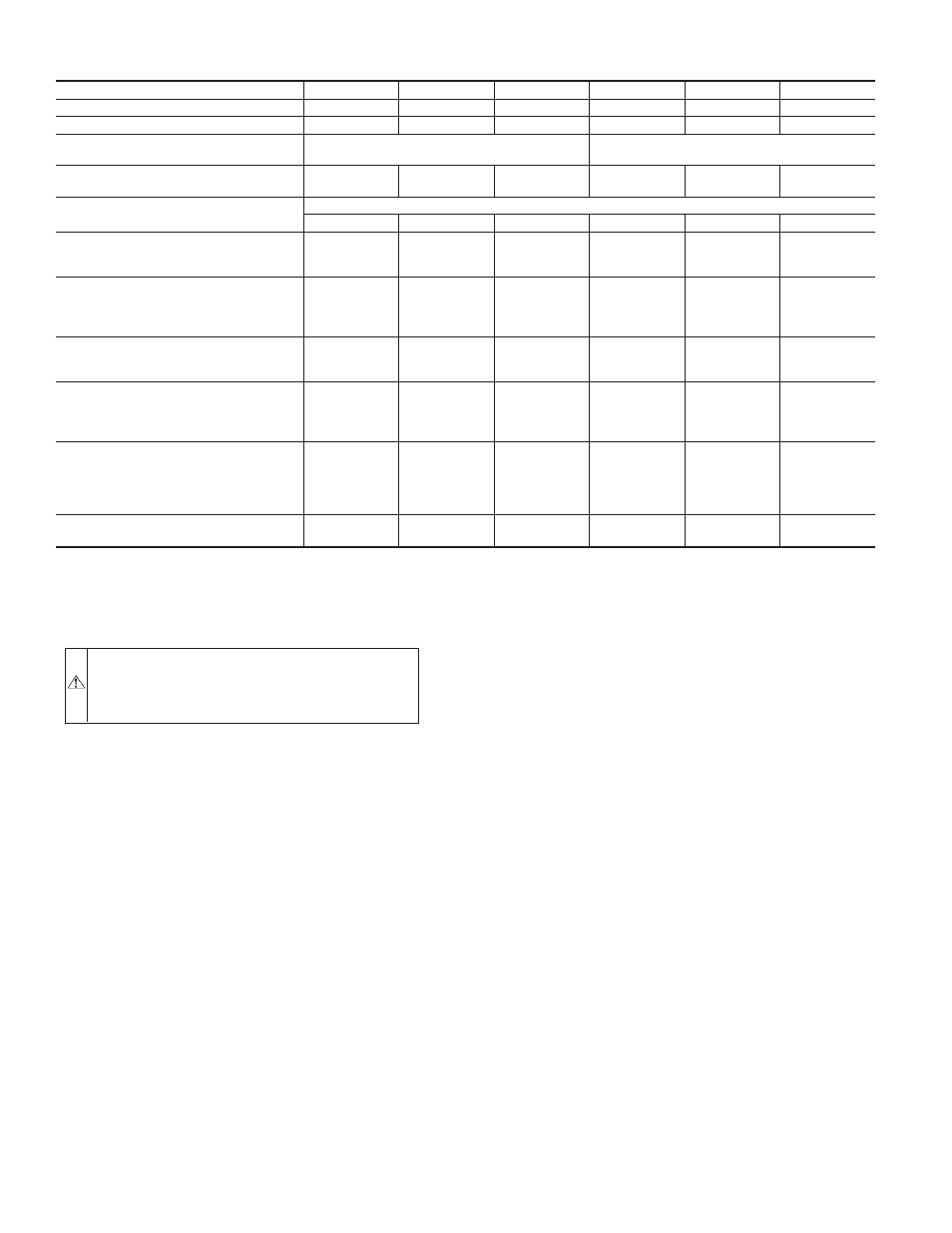

TABLE 1—PHYSICAL DATA—UNIT 582A (CONTINUED)

UNIT SIZE 582A

048090

048115

048130

060090

060115

060130

NOMINAL CAPACITY (ton)

4

4

4

5

5

5

OPERATING WEIGHT (lb.)

415

415

415

450

450

450

COMPRESSORS

Quantity

Scroll

1

Reciprocating

1

REFRIGERANT (R-22)

Quantity (lb.)

6.0

6.0

6.0

8.0

8.0

8.0

REFRIGERANT METERING DEVICE

Orifice ID (in.)

Acutrol Device

.032

.032

.032

.030

.030

.030

CONDENSER COIL

Rows...Fins/in.

Face Area (sq ft)

1...17

12.3

1...17

12.3

1...17

12.3

2...17

12.3

2...17

12.3

2...17

12.3

CONDENSER FAN

Nominal Cfm

Diameter (in.)

Motor Hp (Rpm)

3600

22

¼ (1100)

3600

22

¼ (1100)

3600

22

¼ (1100)

3600

22

¼ (1100)

3600

22

¼ (1100)

3600

22

¼ (1100)

EVAPORATOR COIL

Rows...Fins/in.

Face Area (sq ft)

3...15

4.7

3...15

4.7

3...15

4.7

4...15

4.7

4...15

4.7

4...15

4.7

EVAPORATOR BLOWER

Nominal Airflow (Cfm)

Size (in.)

Motor Hp (Rpm)

1600

11 X 10

3/4 (1075)

1600

11 X 10

3/4 (1075)

1600

11 X 10

3/4 (1075)

2000

11 X 10

1.0 (1075)

2000

11 X 10

1.0 (1075)

2000

11 X 10

1.0 (1075)

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

Burner Orifice No. (Qty...Drill Size)

Propane Gas

3...38

3...46

3...33

3...42

3...31

3...41

3...38

3...46

3...33

3...42

3...31

3...41

RETURN-AIR FILTERS (in.)†

Throwaway

24 X 30

24 X 30

24 X 30

24 X 30

24 X 30

24 X 30

* Based on altitude of 0 to 2000 ft.

† Required filter sizes shown are based on the larger of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300

ft/minute for throwaway type or 450 ft/minute for high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 in. wg.

—8—