Bryant 582A User Manual

Page 11

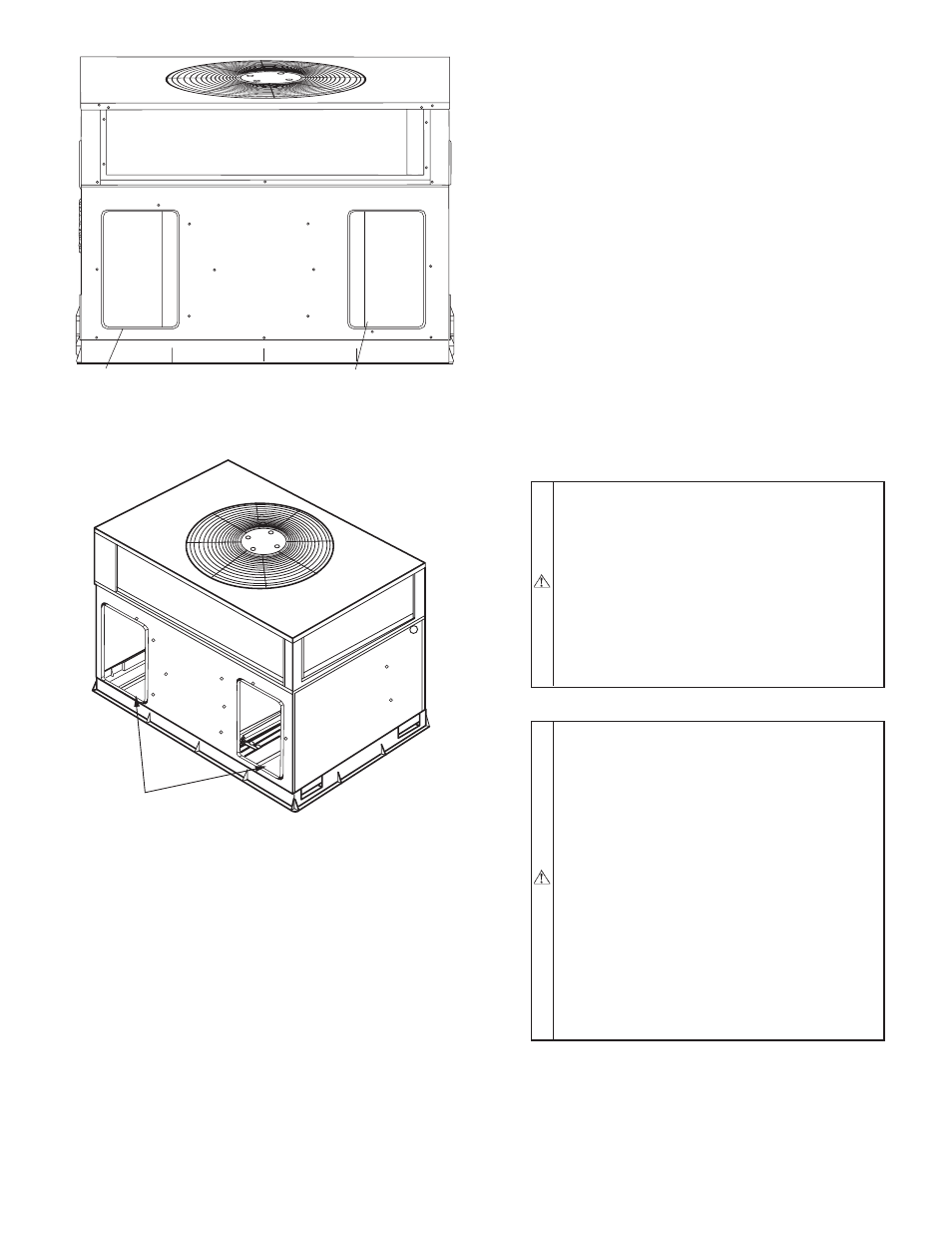

6. Cover both horizontal duct openings with the duct covers

from the accessory duct cover kit. Ensure opening is air-

and watertight.

7. After completing unit conversion, perform all safety checks

and power up unit.

NOTE:

The design and installation of the duct system must be in

accordance with the standards of the NFPA for installation of

nonresidence-type air conditioning and ventilating systems, NFPA

90A or residence-type, NFPA 90B; and/or local codes and

ordinances.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. Units are shipped for horizontal duct installation (by remov-

ing duct covers).

2. Select and size ductwork, supply-air registers, and return-air

grilles according to American Society of Heating, Refrig-

eration and Air Conditioning Engineers (ASHRAE) recom-

mendations.

3. Use flexible transition between rigid ductwork and unit to

prevent transmission of vibration. The transition may be

screwed or bolted to duct flanges. Use suitable gaskets to

ensure weathertight and airtight seal.

4. All units must have field-supplied filters or accessory filter

rack installed in the return-air side of the unit. Recom-

mended sizes for filters are shown in Tables 1 and 2.

5. Size all ductwork for maximum required airflow (either

heating or cooling) for unit being installed. Avoid abrupt

duct size increases or decreases or performance may be

affected.

6. Adequately insulate and weatherproof all ductwork located

outdoors. Insulate ducts passing through unconditioned

space, and use vapor barrier in accordance with latest issue

of Sheet Metal and Air Conditioning Contractors National

Association (SMACNA) and Air Conditioning Contractors

of America (ACCA) minimum installation standards for

heating and air conditioning systems. Secure all ducts to

building structure.

7. Flash, weatherproof, and vibration-isolate all openings in

building structure in accordance with local codes and good

building practices.

X.

INSTALL ELECTRICAL CONNECTIONS

WARNING:

The unit cabinet must have an uninter-

rupted, unbroken electrical ground to minimize the pos-

sibility of serious injury if an electrical fault should occur.

This ground may consist of an electrical wire connected

to the unit ground lug in the control compartment, or

conduit approved for electrical ground when installed in

accordance

with

NEC

(National

Electrical

Code)

ANSI/NFPA (latest edition) and local electrical codes. In

Canada, follow Canadian Electrical Code CSA (Canadian

Standards Association) C22.1 and local electrical codes.

Failure to adhere to this warning could result in serious

injury or death.

CAUTION:

Failure to follow these precautions could

result in damage to the unit being installed:

1. Make all electrical connections in accordance with

NEC ANSI/NFPA (latest edition) and local electrical

codes governing such wiring. In Canada, all electrical

connections must be in accordance with CSA standard

C22.1 Canadian Electrical Code Part 1 and applicable

local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit.

DO NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling

through any panel to mount electrical hardware, con-

duit, etc. On 3-phase units, ensure phases are balanced

within 2 percent. Consult local power company for

correction of improper voltage and/or phase imbal-

ance.

A.

HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, waterproof, disconnect switch mounted at, or within

sight from, the unit. Refer to the unit rating plate for maximum

fuse/circuit breaker size and minimum circuit amps (ampacity) for

wire sizing (See Tables 4 and 5 for electrical data).

Fig. 10A Supply and Return Duct Opening

C99011

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

Fig. 10B—Vertical Duct Cover Removed

C99012

DUCT COVERS REMOVED

—11—