Bryant R-22 User Manual

Page 40

If valve is defective:

1. Shut off all power to unit and remove all charge from

system.

2. Check valve design. If valve is of the 3-port design and new

replacement is of the 4-port design, replacement of the

solenoid coil and wire leads is necessary. Valve bodies are

interchangeable, but solenoid and wires are not. Three-port

reversing valve and solenoid coil with leads must be used

together. New solenoid coil cannot be used on a 3-port

valve.

Four-port reversing valve uses solenoid with quick-connect

terminals for leads connection. Old solenoid coil cannot be

used on 4-port reversing valve. If for any reason a new wire

cord is not available, cut the leads on the old solenoid coil

as close to the coil as possible. Terminate the leads with 2

female 1/4-in. quick-connects. Connect terminals to new

solenoid and tape connection to insulate and provide

moisture barrier. Replace these wires as soon as wire cord

is available. See RCD (Replacement Component Catalog)

for proper cord part number.

3. Remove solenoid coil from valve body. Remove valve by

cutting it from system with tubing cutter. Repair person

should cut in such a way that stubs can be easily rebrazed

back into system. Do not use hacksaw. This introduces

chips into system that cause failure. After defective valve is

removed, wrap it in wet rag and carefully unbraze stubs.

Save stubs for future use. Because defective valve is not

overheated, it can be analyzed for cause of failure when it

is returned.

4. Braze new valve onto used stubs. Keep stubs oriented

correctly. Scratch corresponding matching marks on old

valve and stubs and on new valve body to aid in lining up

new valve properly. When brazing stubs into valve, protect

valve body with wet rag to prevent overheating.

5. Use slip couplings to install new valve with stubs back into

system. Even if stubs are long, wrap valve with a wet rag to

prevent overheating.

6. After valve is brazed in, check for leaks. Evacuate and

charge system. Operate system in both modes several times

to be sure valve functions properly.

VII.

THERMOSTATIC-EXPANSION VALVES (TXV)

The types of TXVs used in condensing-unit and heat-pump

systems are as follows:

Rapid-Pressure Balance (RPB)—Has a special bleed port that

allows rapid bleed-through of pressure after system shutdown until

pressure equalization occurs within approximately 1 to 2 minutes.

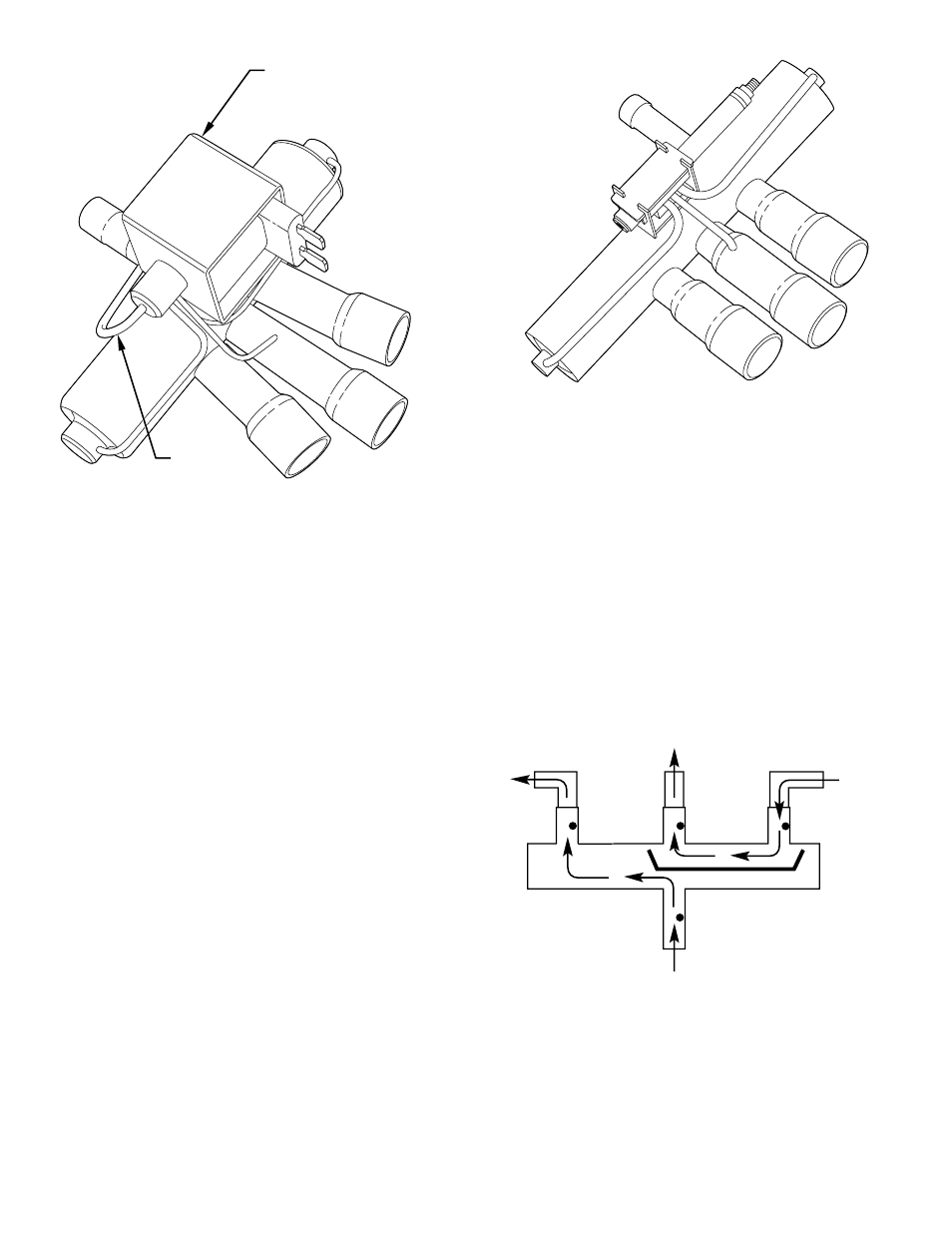

NEW SOLENOID COIL

4TH PORT

4 PORT DESIGN

A91456

3 PORT DESIGN

A91457

Fig. 46—Reversing Valve

Fig. 47—Reversing Valve (Cooling Mode or Defrost

Mode, Solenoid Energized)

A88342

FROM INDOOR COIL VIA

SERVICE VALVE ON

OUTDOOR COIL

TO

ACCUMULATOR

TO OUTDOOR

COIL

TP-4

TP-3

TP-2

TP-1

FROM COMPRESSOR

DISCHARGE LINE

—40—