Bryant R-22 User Manual

Page 37

CAUTION:

Due to the high pressure of nitrogen, it

should never be used without a pressure regulator on the

tank.

Leaks in a system pressurized with refrigerant can be spotted with

a leak detector that detects extremely small refrigerant leaks. This

discussion assumes that system is pressurized with either all

refrigerant or a mixture of nitrogen and refrigerant.

If system has been operating for some time, make first check for

a leak visually. Since refrigerant carries a small quantity of oil,

traces of oil at any joint or connection are an indication that

refrigerant is leaking at that point.

A simple and inexpensive method of testing for leaks is to use soap

bubbles. Any solution of water and soap may be used. Soap

solution is applied to all joints and connections in system. A small

pinhole leak is located by tracing bubbles in soap solution around

leak.

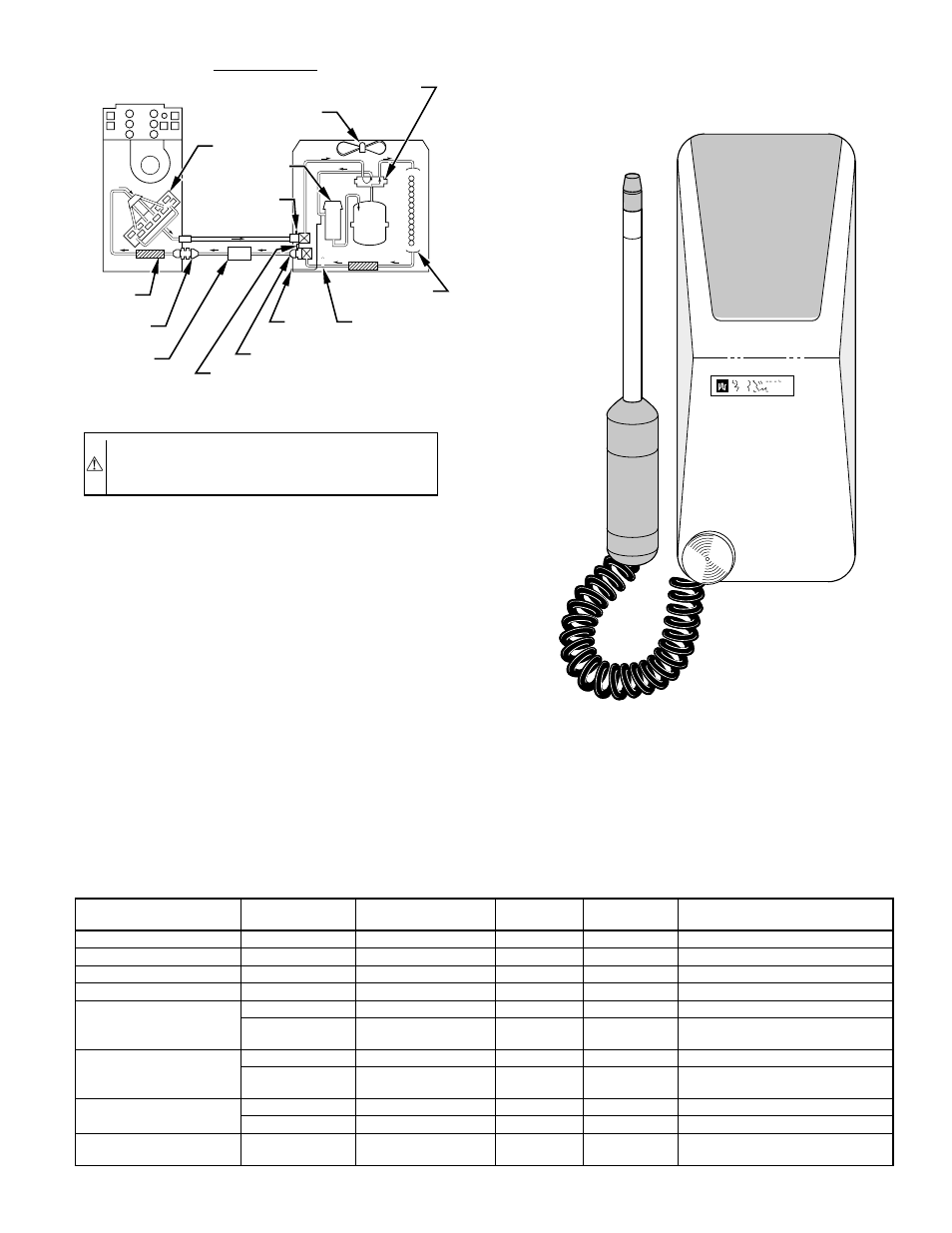

Use electronic leak detector to check for leaks. This unquestion-

ably is the most efficient and easiest method for checking leaks.

There are various types of electronic leak detectors. Generally

speaking, they are all portable, and most are lightweight, consist-

ing of a box with several switches and a probe or sniffer. Detector

is turned on and probe is passed around all fittings and connections

in system. Leak is detected by either a movement of a pointer on

detector dial, by a buzzing sound, or a light.

In all instances, when a leak is found, system charge must be bled

down and leak repaired before final charging and operation. After

leak testing or leak is repaired, evacuate system, and recharge with

correct refrigerant charge.

III.

BRAZING

When brazing is required in the refrigeration system, certain basics

should be followed:

1. Clean joints make the best joints. To clean:

a. Remove all oxidation from surfaces to a shiny finish

before brazing.

TABLE 19—24V PIN CONNECTION TROUBLESHOOTING

MODE OF OPERATION

18-PIN CONNECTOR

TERMINAL

DESIGNATION

LOCATION ON

CONTROL BOARD

VOLTAGE

PATH

VOLTAGE

REQUIRED

POSSIBLE SOURCE

OF PROBLEM

All

R-C

2-1

Input

24

Check transformer (secondary)

Low-speed Cooling

Y1,0-C

8,6-1

Input

24

Check thermostat

High-speed Cooling

Y1, Y2, 0-C

8,7,6-1

Input

24

Check thermostat

Low-speed Heating

Y1-C

8-1

Input

24

Check thermostat

High-speed Heating

Y1-C

8-1

Input

24

Check thermostat

Y2-C

7-1

Output

24

Outdoor temperature below

speed; change temperature

Defrost

Y1-C

8-1

Input

24

Check thermostat

Y2, W2, 0-C

7,5,6-1

Output

24

Outdoor temperature below 50°F;

Coil temperature less than 30°F

Second Stage of

Auxiliary Heat

Y1, W2-C

7,5-1

Input

24

Check thermostat

W3, Y2-C

9,8-1

Output

24

Check balance-point setting

Cooling Second-

stage Latching

Y1, Y2, 0-C

8,7,6-1

Input

24

Ambient thermistor failure;

Check second-stage POT

Fig. 42—Heat Pump Refrigerant-Flow Diagrams

A88400

COOLING CYCLE

INDOOR COIL

OUTDOOR FAN

REVERSING VALVE

(ENERGIZED)

ACCUMULATOR

OUTDOOR

COIL

LIQUID LINE

PRESSURE SWITCH

(BYPASSING)

COMP

STRAINER

STRAINER

SUCTION

SERVICE

PORT

SUCTION SERVICE

PORT AT SERVICE

VALVE (CLG CYCLE)

(METERING)

INDOOR

FAN

LIQUID LINE SERVICE PORT

AT SERVICE VALVE (CLG CYCLE)

HEAT PUMP

ACCESSORY

FILTER DRIER

(DUAL FLOW)

Fig. 43—Leak Detector

A88401

—37—