Bryant R-22 User Manual

Page 16

Cycle-protector device is simple to troubleshoot. Only a voltmeter

capable of reading 24v is needed. Device is in control circuit;

therefore, troubleshooting is safe with control power (24v) on and

high-voltage power off.

With high-voltage power off, attach voltmeter leads across T1 and

T3 and set thermostat so that Y terminal is energized. Make sure

all protective devices in series with Y terminal are closed.

Voltmeter should read 24v across T1 and T3. With 24v still

applied, move voltmeter lead from T1 terminal to T2 terminal

across T2 and T3. After 5 ± 2 minutes, voltmeter should read 24v,

indicating control is functioning normally. If no time delay is

encountered or device never times out, change control.

V.

CRANKCASE HEATER

Crankcase heater is a device for keeping compressor oil warm. By

keeping oil warm, refrigerant does not migrate to and condense in

compressor shell when the compressor is off. This prevents

flooded starts which can damage compressor.

Crankcase heaters come in 2 basic types: wraparound-(bellyband)

type that is wrapped externally around compressor shell, and

insertion-type that is inserted into compressor oil well in shell of

compressor. Both types are used in outdoor units.

On units that have a single-pole contactor, the crankcase heater is

wired parallel with the contactor contacts and in series with the

compressor. (See Fig. 18.) When the contacts are open, a circuit is

completed from the line side of the contactor, through the

crankcase heater, through the run windings of the compressor, and

to the other side of the line. When the contacts are closed, there is

no circuit through the crankcase heater because both leads are

connected to the same side of the line. This allows the heater to

operate when the system is not calling for heating/cooling. The

heater does not operate when the system is calling for

heating/cooling. On units with 2 or 3 pole contactors, the crank-

case heater is connected to the line side of the contactor and is not

controlled by the contactor contacts.

The crankcase heater is powered by high-voltage power of unit.

Use extreme caution troubleshooting this device with power on.

The easiest method of troubleshooting is to apply voltmeter across

crankcase heater leads to see if heater has power. Do not touch

heater. Carefully feel area around crankcase heater. If warm,

crankcase heater is probably functioning. Do not rely on this

method as absolute evidence heater is functioning. If compressor

has been running, the area will still be warm.

With power off and heater leads disconnected, check across leads

with ohmmeter. Do not look for a specific resistance reading.

Check for resistance or an open circuit. Change heater if an open

circuit is detected. Some crankcase heaters in this series of units

are equipped with a crankcase-heater switch. This energy-saving

device shuts off power to heater when temperatures are high

enough that heater is not needed. Be sure this switch is functioning

normally before condemning crankcase heater.

VI.

TIME-DELAY RELAY

The time-delay relay (TDR) is a solid-state-controlled, recycle-

delay timer which keeps the indoor blower operating for 90 sec

after thermostat is satisfied. This delay enables the blower to

remove residual cooling in the coil after compression shutdown,

T3

T1

T2

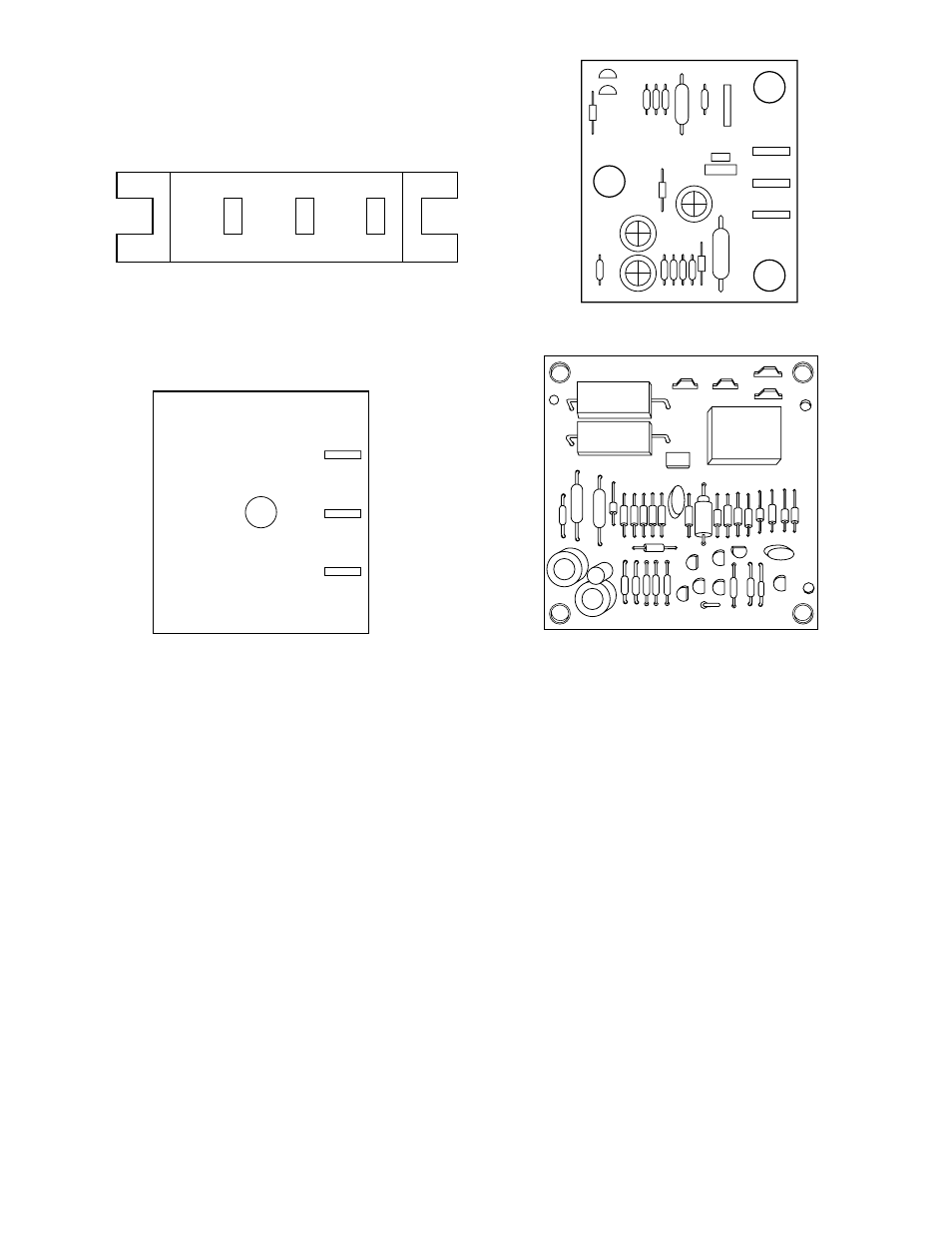

HN67ZA002

A91438

A91439

T3

T1

HN67ZA003

T2

T3

T1

HN67ZA008

T2

A94005

T1 YEL

T2 VIO

T3 BLK

T3 BLK

HN67PA025

A91440

Fig. 15—Cycle-Protector Device

—16—