Scroll gas flow – Bryant R-22 User Manual

Page 28

5. Scratch matching marks on stubs in old compressor. Make

corresponding marks on replacement compressor.

6. Use torch to remove stubs from old compressor and to

reinstall them in replacement compressor.

7. Use copper couplings to tie compressor back into system.

8. Evacuate system, recharge, and check for normal system

operation.

9. Copeland CR-6 and scroll compressors have copper-plated,

steel-suction ports. Excess heat during brazing will burn off

copper plating. See Brazing section for additional informa-

tion.

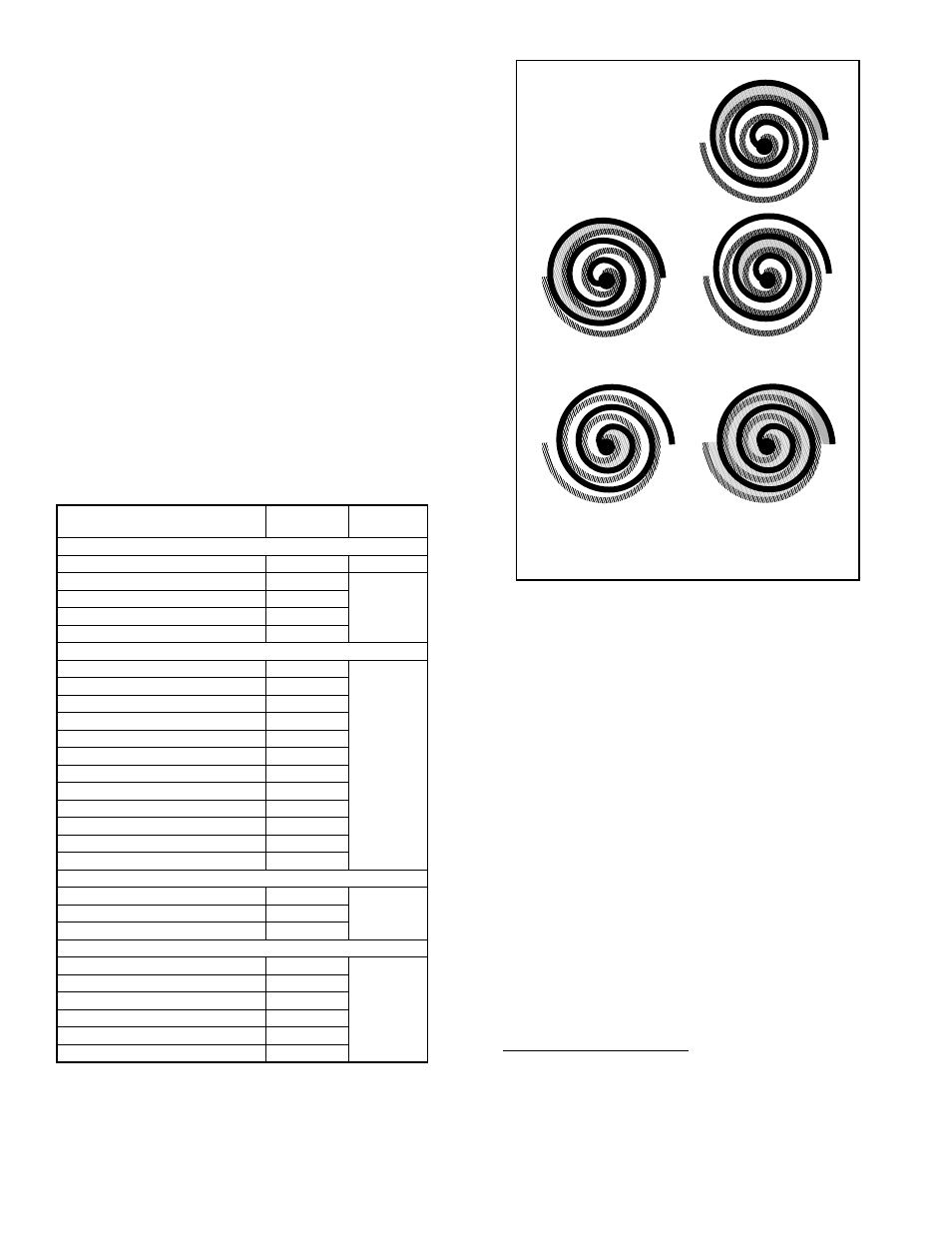

COPELAND SCROLL COMPRESSOR

I.

FEATURES

The scroll compressor pumps refrigerant through the system by the

interaction of a stationary and an orbiting scroll. (See Fig. 29.) The

scroll compressor has no dynamic suction or discharge valves, and

it is more tolerant of stresses caused by debris, liquid slugging, and

flooded starts. Due to the design of the scroll compressor, the

internal compression components unload (equalize pressure) on

shutdown. The white oil (Sontex 200LT) used in the scroll is

compatible with 3GS oil, which can be used if additional oil is

required. (See Table 13 for oil recharge requirements.)

II.

TROUBLESHOOTING

Troubleshooting mechanical or electrical problems in a scroll

compressor is the same as for a reciprocating compressor, except

that a scroll compressor should never be allowed to pump into a

vacuum. If a pumpdown procedure is used, the scroll compressor

is capable of pumping into a vacuum very quickly, which could

cause fusite arcing and compressor failure. See Step IV of

Reciprocating Compressor section for removal and replacement.

III.

DISCHARGE THERMOSTAT

Some scroll compressors have a discharge thermostat that recip-

rocating compressors do not have. This thermostat is mounted in a

well in the top of the compressor shell to sense if the discharge

temperature reaches 290°F and shuts down the compressor to

prevent damage to it. When the temperature of the thermostat

reaches 140°F, power is restored to the compressor.

To determine if the thermostat is operating properly, either attach

the thermocouple of an electronic thermometer to the dome of the

compressor near the thermostat, or remove the thermostat and

place the thermocouple inside the well. The electronic thermom-

eter must be capable of reading at least 300°F. Start the unit and let

it run for at least 15 minutes to obtain normal operating conditions.

Watch the thermometer to see if it is approaching 270°F. If the

thermocouple is located on the dome near the discharge thermo-

stat, there could be a 20° difference between well and dome

temperatures. If the temperature approaches 270°F, repair system

problem, such as low charge, blocked condenser coil, and so forth.

If the temperature does not approach 270°F, replace discharge

thermostat.

Replacing Discharge Thermostat

To replace the discharge thermostat, refer to the Installation

Instructions packaged with the replacement discharge thermostat

kit. (See Fig. 30.)

IV.

DISCHARGE SOLENOID VALVE

Some larger units equipped with scroll compressors contain a

solenoid valve that is piped between the discharge tube and suction

tube of the compressor. The purpose of the solenoid valve is to

TABLE 13—COMPRESSOR OIL RECHARGE

COMPRESSOR MODEL

RECHARGE

(FL. OZ.)

OIL TYPE

Carlyle/Scroll

″

J

″

Type

44

Suniso 3GS

SC, SRD450AC

34

Zerol 150

w/3 percent

Syn-O-Ad

SR

52

SRH482, SRY482

68

SRH602, SRY602

70

Copeland

CRG3, CRH3, CRJ3, CRK3, CRL3

51

Suniso 3GS

CRN5, CRP5, CRT5, CTH1, CTL1

66

CRC4, CRZ4

36

CR16K6 THROUGH CR42K6

42

*ZR18K1

19

*ZR23K1, ZR28K1

24

*ZR34K1

30

*ZR40K1

34

*ZR49K1-PFV

56

*ZR49K2-TF5, ZR49K2-TFD

56

*ZR61K2-PFV

56

*ZR61K2-TF5, ZR61K2-TFD

66

Tecumseh

AV55

50

Suniso 3GS

AW55

30

AG

60

Bristol

H23A

52

Suniso 3GS

H23B

37

H24A3, H24A4

47

H24A5

52

H25A, H26A

62

H25B, H26B, H29B

32

*Copeland scrolls are charged initially with Sontex 200LT white oil. Since this

oil is not commercially available, use 3GS.

Fig. 29—Scroll Compressor Refrigerant Flow

A90198

Scroll Gas Flow

Compression in the scroll is

created by the interaction of

an orbiting spiral and a

stationary spiral. Gas enters

an outer opening as one of the

spirals orbits.

The open passage is sealed off

as gas is drawn into the spiral.

By the time the gas arrives at

the center port, discharge

pressure has been reached.

Actually, during operation, all

six gas passages are in various

stages of compression at all

times, resulting in nearly con-

tinuous suction and discharge.

As the spiral continues to orbit,

the gas is compressed into an

increasingly smaller pocket.

1

2

3

5

4

—28—