Bryant R-22 User Manual

Page 26

In this type of failure, compressor motor runs and turns compres-

sor, and compressor is pumping. Usually, an internal problem such

as blown head gasket or broken internal-discharge line causes

compressor to pump hot discharge gas back into its own shell

rather than through system.

Using pressure gages on service valves shows high suction and

low discharge pressure readings. Motor currents are lower than

normal. Because hot gas is being discharged into shell, the shell

becomes hot. The hot gas causes compressor motor to cycle off on

its internal protection.

RUNS AND PUMPS, LOW CAPACITY

This failure type is difficult to pinpoint because extent of damage

varies. Compressor is a pump with internal valves that enable

compressor to pump properly. The cylinder has a set of suction and

discharge valves. Any of these parts may become damaged or

broken, causing loss in pumping capacity. Severity of damage

determines amount of capacity loss. Use pressure gages to find any

abnormal system pressures if system charge and other conditions

are normal.

An owner may complain that a unit is not handling the building’s

heating or cooling load. The compressor current draw may be

abnormally low or high. Although this type of failure does occur,

all other possible causes of capacity loss must be eliminated before

condemning compressor.

NOISY COMPRESSOR

Noise may be caused by a variety of internal problems such as

loosened hardware, broken mounting springs, etc. System prob-

lems such as overcharged compressor (especially at start-up) or too

much oil in compressor may also cause excessive noise. Excess oil

in compressor is normally encountered only after a replacement

compressor has been added without purging oil from previous

compressor. As new compressor pumps, excess oil in system

returns and adds to volume already present, causing noise.

COMPRESSOR LEAKS

CAUTION:

Use safety glasses and gloves when han-

dling refrigerants.

Sometimes a leak is detected at weld seam around girth of

compressor or a fitting that joins compressor shell. Many of these

leaks can be repaired and the compressor saved if correct proce-

dure is followed.

1. Turn off all power to unit.

2. Remove and recover all refrigerant from system so that

gage pressures are 0 psi.

3. Clean area around leak to bare metal.

4. Apply flux and repair joint with silver solder. Do not use

low-temperature solder such as 50-50.

5. Clean off excess flux, check for leaks, and apply paint over

repaired area to prevent corrosion.

Do not use this method to repair a compressor leak due to severe

corrosion. Never attempt to repair a compressor leaking at electric

terminals. This type of failure requires compressor replacement.

II.

ELECTRICAL FAILURES

The compressor mechanical pump is driven by an electric motor

within its hermetic shell. In electrical failures, compressor does not

run although external electrical and mechanical systems appear

normal. Compressor must be checked electrically for abnormali-

ties.

Before troubleshooting compressor motor, review this description

of compressor motor-terminal identification.

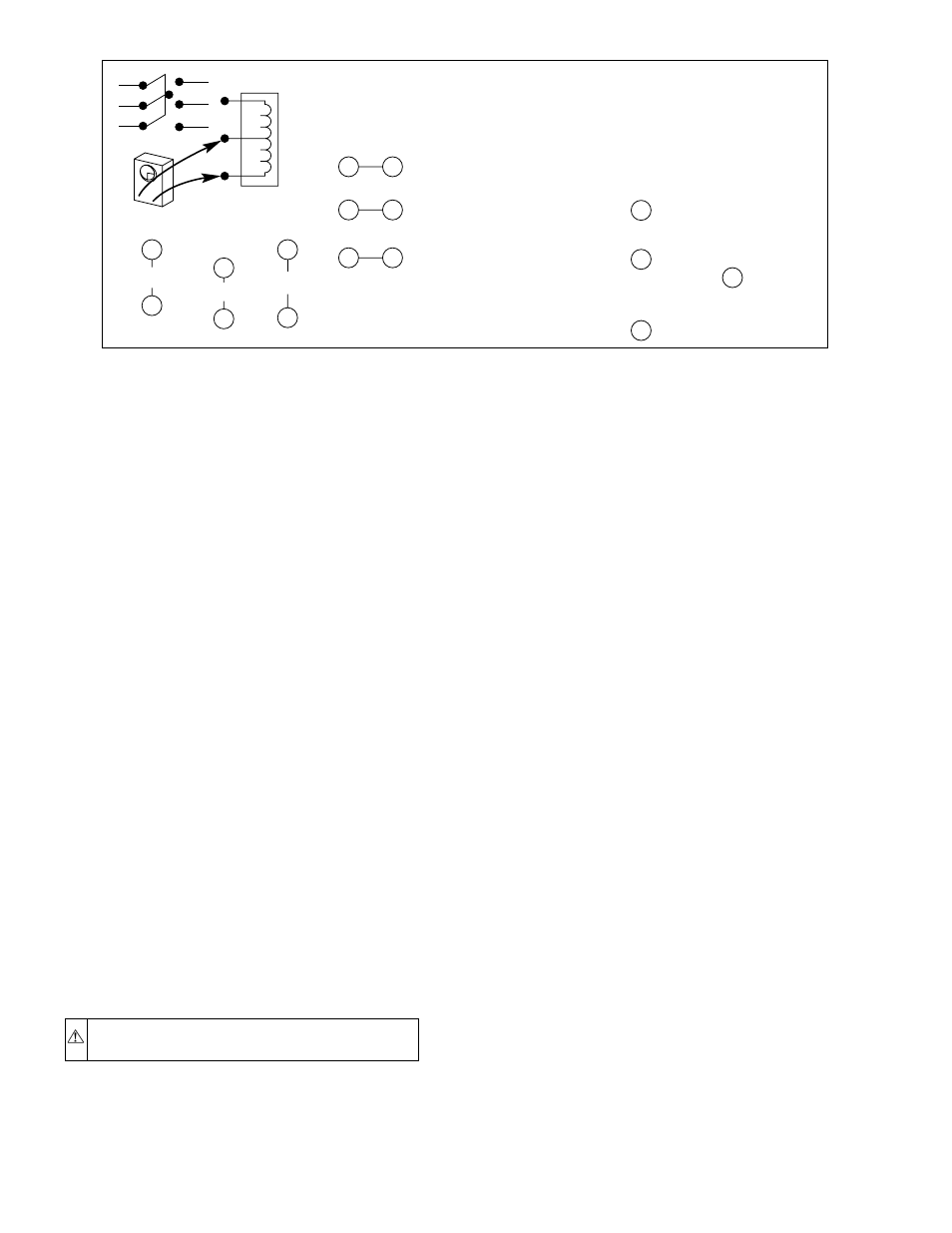

SINGLE-PHASE MOTORS

To identify terminals C, S, and R:

1. Turn off all unit power.

2. Short the run and start capacitors to prevent shock.

3. Remove all wires from motor terminals.

4. Read resistance between all pairs of terminals using an

ohmmeter on 0-10 ohm scale.

5. Determine 2 terminals that provide greatest resistance

reading.

Through elimination, remaining terminal must be common (C).

Greatest resistance between common (C) and another terminal

indicates start winding because it has more turns. This terminal is

start (S). Remaining terminal will be run winding (R). (See Fig.

28.)

NOTE:

If compressor is hot, allow time to cool and internal line

break to reset. There is an internal line-break protector which must

be closed.

THREE-PHASE MOTORS

Resistance readings between all 3 sets of windings should be the

same.

All compressors are equipped with internal motor protection. If

motor becomes hot for any reason, protector opens. Compressor

should always be allowed to cool and protector to close before

troubleshooting. Always turn off all power to unit and disconnect

leads at compressor terminals before taking readings.

Fig. 28—Identifying Internal Connections

A88344

POWER OFF!

OHMMETER

0-10

Ω

SCALE

5.2

Ω

0.6

Ω

5.8

Ω

DEDUCTION:

(EXAMPLE)

TO DETERMINE INTERNAL CONNECTIONS OF SINGLE-

PHASE MOTORS (C,S,R) EXCEPT SHADED-POLE

?

?

?

1

2

2

3

1

3

1

2

3

2

1

3

(GREATEST RESISTANCE)

5.8

Ω

(OHM)

(SMALLEST RESISTANCE)

0.6

Ω

(REMAINING RESISTANCE)

5.2

Ω

2

2

3

1

IS COMMON (C)

BY ELIMINATION

IS COMMON,

THEREFORE, IS

START WINDING (S)

RUN WINDING (R)

START WINDING (S)

IS RUN WINDING (R)

—26—