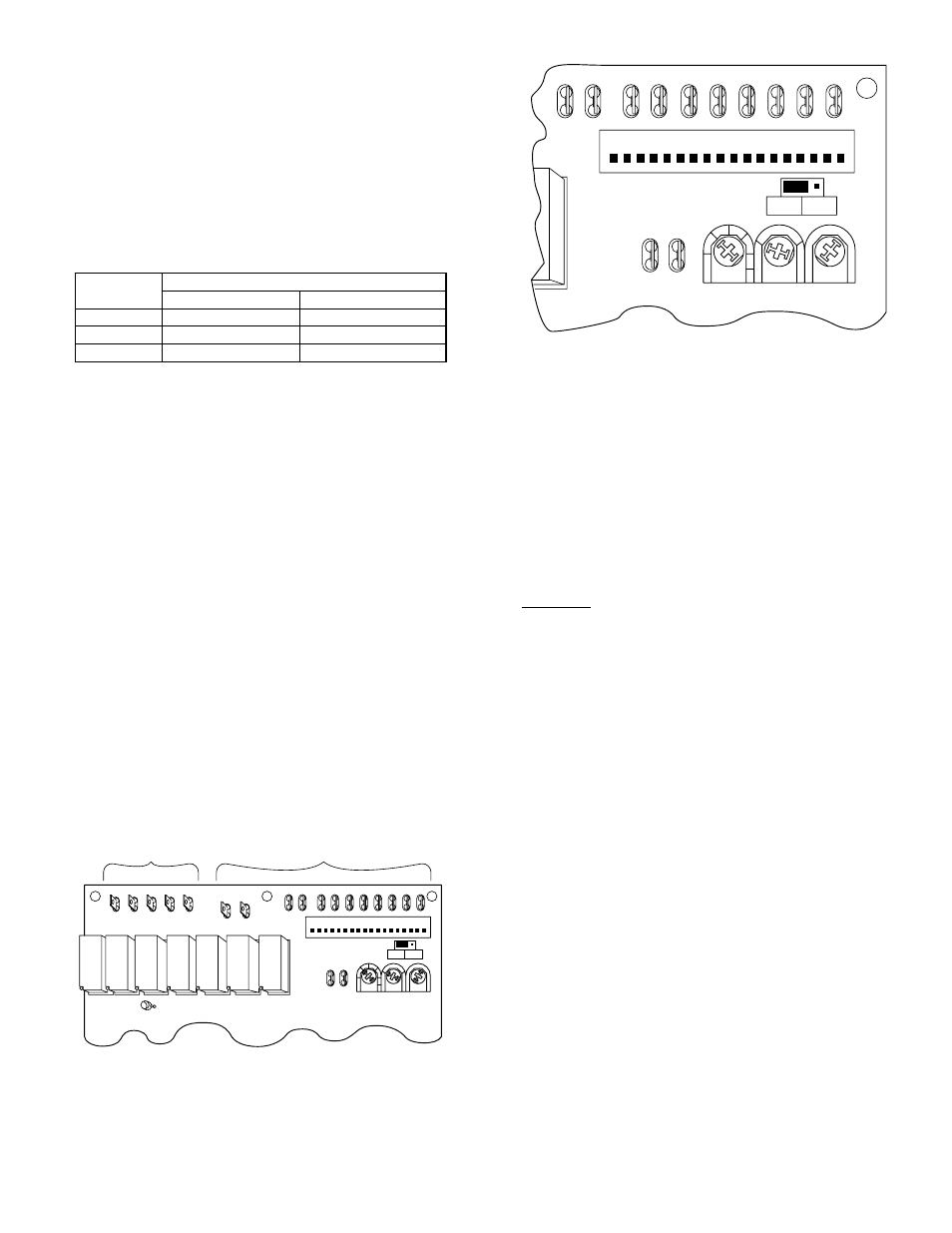

Fig. 33—two-speed control board, Fig. 34—speedup terminals – Bryant R-22 User Manual

Page 31

HEATING OPERATION (HEAT PUMP ONLY)

The 2-speed products utilize a 2-stage-heating indoor thermostat.

The first stage of heating is heat-pump operation (Y1). Auxiliary

backup heat is controlled by second stage (W2). There is a 2°

differential between first and second stage. The control board

determines the compressor speed based on ambient temperature.

See Table 14 for ambient temperatures at which speed changes

occur. When high-speed, heat-pump heating is required, the

control provides a Y2 (24vac) signal back to the thermostat to

energize high-speed-indicator LED.

LED FUNCTION LIGHTS

When using the factory-authorized indoor thermostats with the

2-speed outdoor units, there are 2 locations where system-function

LED-indicator lights are available. The indoor thermostat provides

indicator lights for high- and low-speed operation, system mal-

function, and auxiliary heat for heat pumps. The 2-speed control

board has an LED which provides signals for several system

operations. See Table 15 for LED functions, indicator locations,

and definitions. Table 15 also provides the order of signal

importance if more than 1 signal should occur. The signal to the

indoor thermostat is supplied by the low-voltage

″

L

″

lead.

THREE-SECOND TIME DELAY

Any time the control receives a 24v input, such as Y1 or Y2, there

is a 3-sec time delay before the control function is initiated. This

helps prevent nuisance trips and thermostat

″

jiggling.

″

ONE-MINUTE SPEED-CHANGE TIME DELAY

When the compressor changes speeds from high to low or low to

high, there is a 1-minute time delay before the compressor restarts.

The outdoor fan motor remains running.

FIVE-MINUTE TIME DELAY

The 2-speed-control logic contains a 5-minute time delay that

prevents the unit from short cycling after a thermostat-off cycle or

power interruption. The unit can be forced to operate immediately

by momentarily touching a jumper between the speed-up terminals

of the control board. (See Fig. 33 and 34.) The speed-up feature

will not bypass any other function or time delay.

TWO-MINUTE LOW-SPEED MINIMUM

If the unit has not operated within the past 30 minutes, the unit

operates for a minimum of 2 minutes in low speed upon the next

thermostat high or low demand.

CRANKCASE-HEATER OPERATION

The 2-speed control energizes the crankcase heater during the

unit’s off cycle when the outdoor ambient is below 75°F.

OUTDOOR FAN-MOTOR OPERATION

The 2-speed control energizes the outdoor fan any time the

compressor is operating. The outdoor fan remains energized during

the 1-minute, speed-change time delay and if a pressure switch or

compressor PTC overload should trip.

If the outdoor fan motor won’t run, check the header-pin housing.

(See Fig. 37.) There should be NO jumper wire between Terminals

15 and 16.

Heat Pumps

After the termination of a defrost cycle, the outdoor fan delays

come on for 20 sec. This allows the refrigeration system to recover

the outdoor coil heat and minimize the

″

steam cloud

″

effect.

SECOND-STAGE LATCHING

When low-speed cooling operation no longer satisfies the first

stage of the indoor thermostat, the indoor temperature will increase

by 2° until second stage is energized. After high-speed cooling

satisfies second stage, it returns to low-speed cooling operation. If

desired, the installer may select to have high-speed cooling by

energizing Y1. High speed will stay energized until Y1 is satisfied.

This eliminates the temperature drop between the first and second

stages of indoor thermostat, holding room temperature closer to set

point.

To utilize this function, the unit capacity should be plotted versus

the heat gain of the structure, which provides the system’s balance

point when the structure requires high-speed capacity. (See Fig.

35.)

Second-stage latching can be selected by rotating the potentiom-

eter (POT) to the desired outdoor second-stage latching tempera-

ture (See Fig. 34.) The temperatures that can be selected are 85°,

90°, 95°, 100°, and 105°F. The POT is factory set at 105°F.

ZONE SELECTION

If the stage–2 latch POT is set to ZONE position, the compressor

operating speed in either heat or cool mode is determined by the

Y1 and/or Y2 inputs. The system operates in low speed with a Y1

input and high speed with Y2 or Y1-and-Y2 input. This allows the

multistage-zoning system to determine what speed is needed

regardless of outdoor temperature or switchover point.

DEFROST TIME SELECTION

The defrost interval can be field selected, depending on local or

geographic requirements. It is factory set at 90 minutes and can be

changed to either 30 or 50 minutes by rotating the defrost-time

POT. (See Fig. 34.)

TABLE 14—AMBIENT TEMPERATURE FOR HIGH- AND

LOW-SPEED OPERATION

UNIT

SIZE

AMBIENT TEMPERATURE (°F)

High Speed

Low Speed

036

30 or less

31 or greater

048

33 or less

34 or greater

060

40 or less

41 or greater

Fig. 33—Two-Speed Control Board

A93569

HIGH VOLTAGE

LOW VOLTAGE

L2

LO

HI

CCH

ODF

O

C

LM1 LM2

DFT1 DFT2 T1

T2

S2

S1

PW2 PW1

P1

1

18

SPEED-UP

STAGE 2

LATCH

DEFROST

TIME

BALANCE

POINT

K7

K6

K5

K4

K3

K2

K1

LED 1

FURN INT

OFF

ON

Fig. 34—Speedup Terminals

A93568

LM1 LM2

DFT1 DFT2 T1

T2

S2

S1

PW2 PW1

P1

1

18

SPEED-UP

STAGE 2

LATCH

DEFROST

TIME

BALANCE

POINT

K7

ZONE

OFF

105

100

95

90

85

FURN INT

OFF

ON

45

40

35

30

25

20

10

15

90

30

50

—31—