Thermistor curve – Bryant R-22 User Manual

Page 34

pressures exceeds 500 psi. The compressor is also protected by 3

PTC devices attached to the motor windings. The PTC’s resistance

is sensed by the 2-speed control board. See Table 16 for resistance

ranges.

MECHANICALLY INTERLOCKED CONTACTORS

The 2-speed products are equipped with mechanically interlocked

contactors. Each contactor has interconnecting linkage, providing

independent interlocks.

The 2-speed control provides the electrical interlock. The contac-

tors are supplied with 240v coils, which reduce the va require-

ments of the low-voltage (24vac) control system.

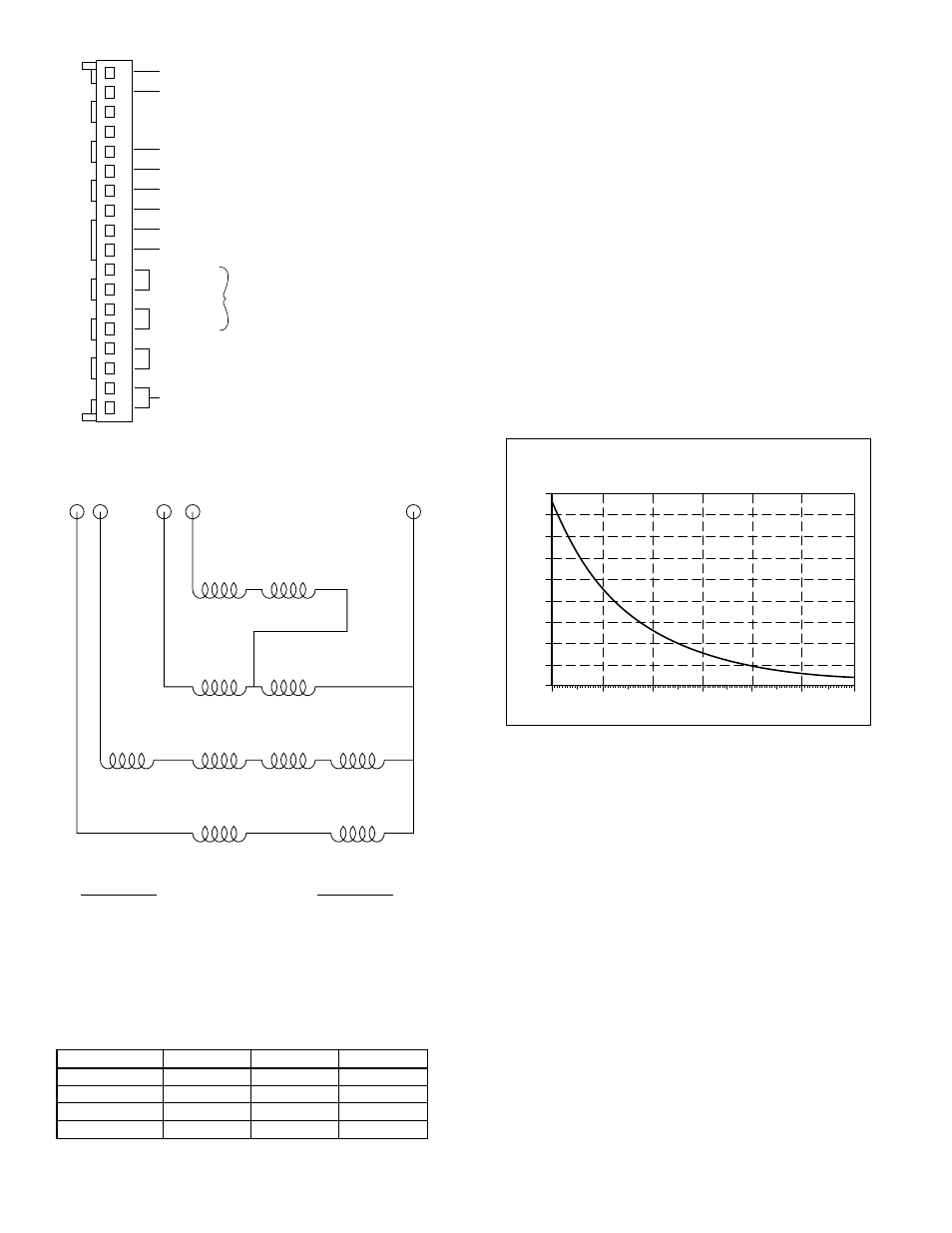

TEMPERATURE THERMISTORS

Thermistors are electronic devices which sense temperature. As

the temperature increases, the resistance decreases. Two ther-

mistors are used to sense temperature: one senses outdoor ambient,

and the other senses coil temperature (heat pump only). Refer to

Fig. 39 for resistance values versus temperature.

If the outdoor ambient thermistor should fail, a malfunction signal

appears on the indoor thermostat and 2-speed control. The control

does not initiate second-stage latching, crankcase heater is turned

on during all off-cycles, heating defaults to high speed, and defrost

initiates on demand from coil thermistor. (See Table 17.)

If the outdoor coil thermistor should fail, a malfunction signal

appears on the indoor thermostat and 2-speed control. The control

defrosts every 90 minutes of heating operation and terminates in 5

minutes. (See Table 17.)

V.

LED FUNCTION/MALFUNCTION LIGHTS

The 2-speed control is equipped with an LED function/ malfunc-

tion light.

NOTE:

Only malfunction signal appears at thermostat. Both

function and malfunction signals appear at control board. (See Fig.

33 for LED location.) Table 15 provides the function/malfunction

code, location, and definition.

VI.

TROUBLESHOOTING

NOTE:

Troubleshooting charts for air conditioning and heat

pump units are provided in the back of this manual — see Fig. 52,

53, and 54.

COMPRESSOR WINDING CHECK

The 2-speed compressor is nothing more than 2 single-phase

motors within 1 compressor shell. When the compressor fails to

start or run, there are 3 tests that can be made: open, ground, or

short. This compressor has no internal line-break overload; how-

ever, it does have PTC motor protectors. See Compressor PTC-

Overload Protection section for PTC overload information.

Fig. 37—Header-Pin Housing

A93576

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

JUMPER FOR

HEAT PUMP ONLY

C - TRANSFORMER COMMON

R - TRANSFORMER LINE

W2 - FIRST STAGE AUXILIARY HEAT

O - REVERSING VALVE

Y2 - SECOND STAGE COOLING/HEAT PUMP

L - MALFUNCTION LIGHT

Y1 - FIRST STAGE COOLING/HEAT PUMP

W3 - SECOND STAGE AUXILIARY HEAT

4 - TON

5 - TON

IF NO JUMPER IS

INSTALLED, DEFAULT

IS 3 - TON

Fig. 38—Energizing Windings

A92015

T3 T8

T7

T2

T1

EXTERNAL MAIN

MAIN WINDING

4 POLE START

2 POLE START

LOW SPEED

(L1) T1

(L2) T7 + T8

HIGH SPEED

(L1) T1 + T7

(L2) T2 + T3

TABLE 18—TWO-SPEED COMPRESSOR

(WINDING RESISTANCE AT 70°F ± 2°)

WINDING

3 TON

4 TON

5 TON

T1-T2

0.80

0.70

0.60

T1-T3

3.20

2.20

1.80

T1-T7

1.30

1.00

1.00

T1-T8

3.10

2.20

2.00

Fig. 39—Resistance Values Versus Temperature

A91431

0

10

20

30

40

50

60

70

80

90

0

20

40

60

80

100

120

TEMPERATURE (DEG. F)

RESISTANCE (KOHMS)

THERMISTOR CURVE

—34—