Bunn G9-2T DBC User Manual

Page 20

20

SERVICE (Cont.)

DC MOTOR AND GRIND CHAMBER - G1MD ONLY

(cont.)

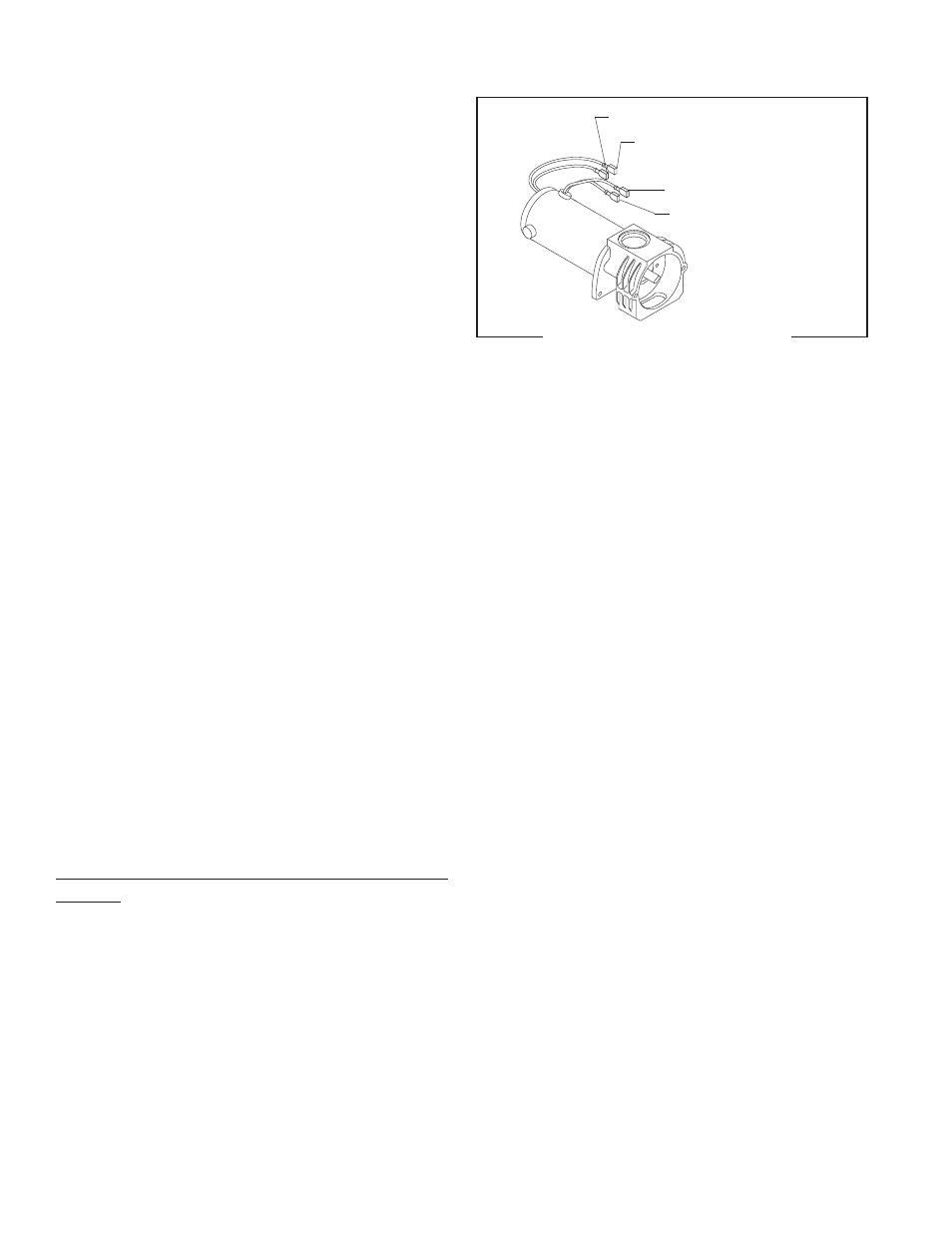

BLU to BLU from Rectifier

BLU to WHI/BLU from

Relay (3)

RED to Rectifier (-)

BLK to Rectifier (+)

FIG. 7 DC MOTOR TERMINALS

P1710

10. Remove motor and bracket out the rear of the

grinder housing.

11. Remove the two .250”-20 screws securing the

motor to the front of the mounting bracket.

12. Remove the two #10-32 screws securing the mo-

tor to rear of the mounting bracket.

13 Remove motor from bracket.

14. Clean all grinding burrs and mounting surfaces

before reassembly.

15 Place the new motor with hopper collar into posi-

tion on the motor mounting bracket.

16. Using two .250”-20 screws secure the motor to

the front of the mounting bracket.

17. Using two #10-32 screws secure the motor to the

rear of the mounting bracket

18. Install motor and bracket through the rear of the

grinder, position on the grinder housing bracket

and secure with four .312”-18 screws (20), rubber

washers (22) and flat washers (21).

19. Install stationary burr (9) to the grind chamber

housing using two .250”-20 screws (8).

20. Install burr (7), burr auger rotor/spring assembly

(3) and burr rotor disc (4) on to motor shaft.

21. Install grind selector dial plate and grind selector

knob assembly (2) on the grind chamber housing

and secure with two .250”-20 screws.

22. Refer to Fig. 7 and reconnect the wires to the

motor and Fig. 37 and reconnect the wires to the

rectifier.

23. Refer to ADJUSTMENTS section and reset the

burrs.

Removal and Replacement - Grind Chamber - Refer

to Fig. 8:

1. Loosen the two set screws (16) securing the grind

selector knob to the grind selector dial plate (18)

and remove knob.

2. Remove the adjusting screw w/bearing (19). In-

spect adjusting screw w/bearing for wear. Replace

if excessively worn or damaged.

3. Remove the two .250”-20 screws (1) securing the

grind selector dial plate (18) to the grind housing

and remove plate.

4. Slide burr auger rotor/spring assembly (3) off of

the grinder motor shaft with burr (7) as an as-

sembly.

5. Remove the two .250”-20 screws (5) securing

burr (7) to burr auger rotor/spring assembly (6),

remove burr (7) and burr rotor disc (4). Inspect

burr (7) for wear. Replace if excessively worn or

damaged.

6. Remove the two .250”-20 screws (8) securing the

stationary burr (9) to grind chamber housing and

remove burr. Inspect for wear. Replace if exces-

sively worn or damaged.

NOTE: Burrs are serviced in sets of two with hard-

ware.

7. Remove bushing (10) and washer (11) from

grinder motor shaft. Inspect for wear. Replace if

excessively worn or damaged.

8. Clean all grinding burrs and mounting surfaces

before reassembly.

9. Install washer (11) and bushing (10) onto the

grinder motor shaft.

10. Install stationary burr (9) inside the grind chamber

and secure with two .250” -20 screws (8).

41545 122209