Bryant Induced-Combustion 4-Way Multipoise 310AAV User Manual

Page 5

3. Provide adequate combustion and ventilation air to the furnace

space as specified in “Air for Combustion and Ventilation”

section.

4. Combustion products must be discharged outdoors. Connect

this furnace to an approved vent system only, as specified in

the “Venting” section of these instructions.

5. Never test for gas leaks with an open flame. Use a commer-

cially available soap solution made specifically for the detec-

tion of leaks to check all connections, as specified in the “Gas

Piping” section.

6. Always install furnace to operate within the furnace’s intended

temperature-rise range with a duct system which has an

external static pressure within the allowable range, as speci-

fied in the “Start-Up, Adjustments, and Safety Check” section.

See furnace rating plate.

7. When a furnace is installed so that supply ducts carry air

circulated by the furnace to areas outside the space containing

the furnace, the return air shall also be handled by duct(s)

sealed to the furnace casing and terminating outside the space

containing the furnace. See “Air Ducts” section.

8. A gas-fired furnace for installation in a residential garage must

be installed as specified in the warning box in the “Location”

section.

9. The furnace is not to be used for temporary heating of

buildings or structures under construction. See page 7 caution

box regarding the heating of buildings under construction.

10. These Multipoise Gas-Fired Furnaces are CSA (formerly

A.G.A. and C.G.A.) design-certified for use with natural and

propane gases (see furnace rating plate) and for installation in

alcoves, attics, basements, closets, utility rooms, crawlspaces,

and garages. The furnace is factory-shipped for use with

natural gas. A CSA listed gas conversion kit is required to

convert furnace for use with propane gas.

11. See Fig. 2 for required clearances to combustible construction.

12. Maintain a 1-in. clearance from combustible materials to

supply air ductwork for a distance of 36 inches horizontally

from the furnace. See NFPA 90B or local code for further

requirements.

13. These furnaces SHALL NOT be installed directly on carpet-

ing, tile, or any other combustible material other than wood

flooring. In downflow installations, factory accessory floor

base MUST be used when installed on combustible materials

and wood flooring. Special base is not required when this

furnace is installed on manufacturer’s Coil Assembly Part No.

CD5 or CK5, or when Coil Box Part No. KCAKC is used. See

Fig. 2 for clearance to combustible construction information.

INTRODUCTION

This Series 120/C 4–way multipoise Category I fan-assisted

furnace is CSA design-certified. A Category I fan-assisted furnace

is an appliance equipped with an integral mechanical means to

either draw or force products of combustion through the combus-

tion chamber and/or heat exchanger. The furnace is factory-

shipped for use with natural gas. A CSA (A.G.A. and C.G.A.)

listed gas conversion kit is required to convert furnace for use with

propane gas. This furnace is not approved for installation in

mobile homes, recreational vehicles, or outdoors.

This furnace is designed for minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°F db

such as when used with a night setback thermostat. Return-air

temperature must not exceed 85°F db. Failure to follow these

return-air temperature limits may affect reliability of heat exchang-

ers, motors, and controls. (See Fig. 3.)

For accessory installation details, refer to the applicable instruction

literature.

NOTE:

Remove all shipping brackets and materials before oper-

ating the furnace.

CODES AND STANDARDS

Follow all national and local codes and standards in addition to

these instructions. The installation must comply with regulations

of the serving gas supplier, local building, heating, plumbing, and

other codes. In absence of local codes, the installation must

comply with the national codes listed below and all authorities

having jurisdiction.

→

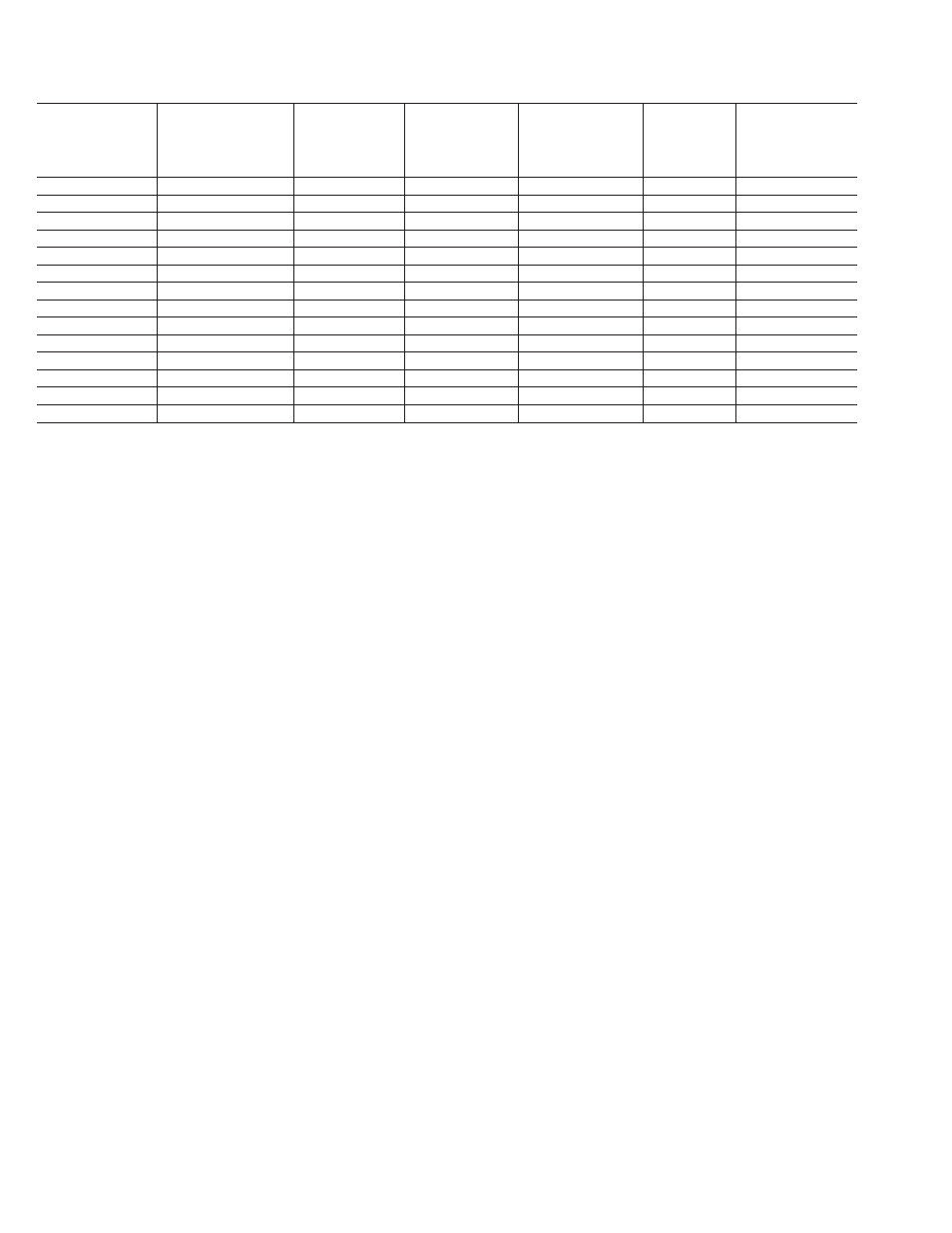

Table 1—Dimensions (IN.)

FURNACE

SIZE

A

CABINET WIDTH

D

SUPPLY-AIR

WIDTH

(IN.)

E

RETURN-AIR

WIDTH

(IN.)

F

C.L. TOP AND

BOTTOM

FLUE COLLAR

(IN.)

FLUE

COLLAR*

(IN.)

SHIP WT. (LB)

045-08/024045

14-3/16

12-9/16

12-11/16

9-5/16

4

104

045-12/036045

14-3/16

12-9/16

12-11/16

9-5/16

4

107

070-08/024070

14-3/16

12-9/16

12-11/16

9-5/16

4

111

070-12/036070

14-3/16

12-9/16

12-11/16

9-5/16

4

115

070-16/048070

17-1/2

15-7/8

16

11-9/16

4

126

090-14/042090

17-1/2

15-7/8

16

11-9/16

4

127

090-16/048090

21

19-3/8

19-1/2

13-5/16

4

140

090-20/060090

21

19-3/8

19-1/2

13-5/16

4

146

110-12/036110

17-1/2

15-7/8

16

11-9/16

4

135

110-16/048110

21

19-3/8

19-1/2

13-5/16

4

146

110-22/066110

21

19-3/8

19-1/2

13-5/16

4

152

135-16/048135

21

19-3/8

19-1/2

13-5/16

4

149

135-22/066135

24-1/2

22-7/8

23

15-1/16

4

163

155-20/060155

24-1/2

22-7/8

23

15-1/16

4

170

* 5” or 6” vent connector may be required in some cases.

4

→

→