Bryant Induced-Combustion 4-Way Multipoise 310AAV User Manual

Page 23

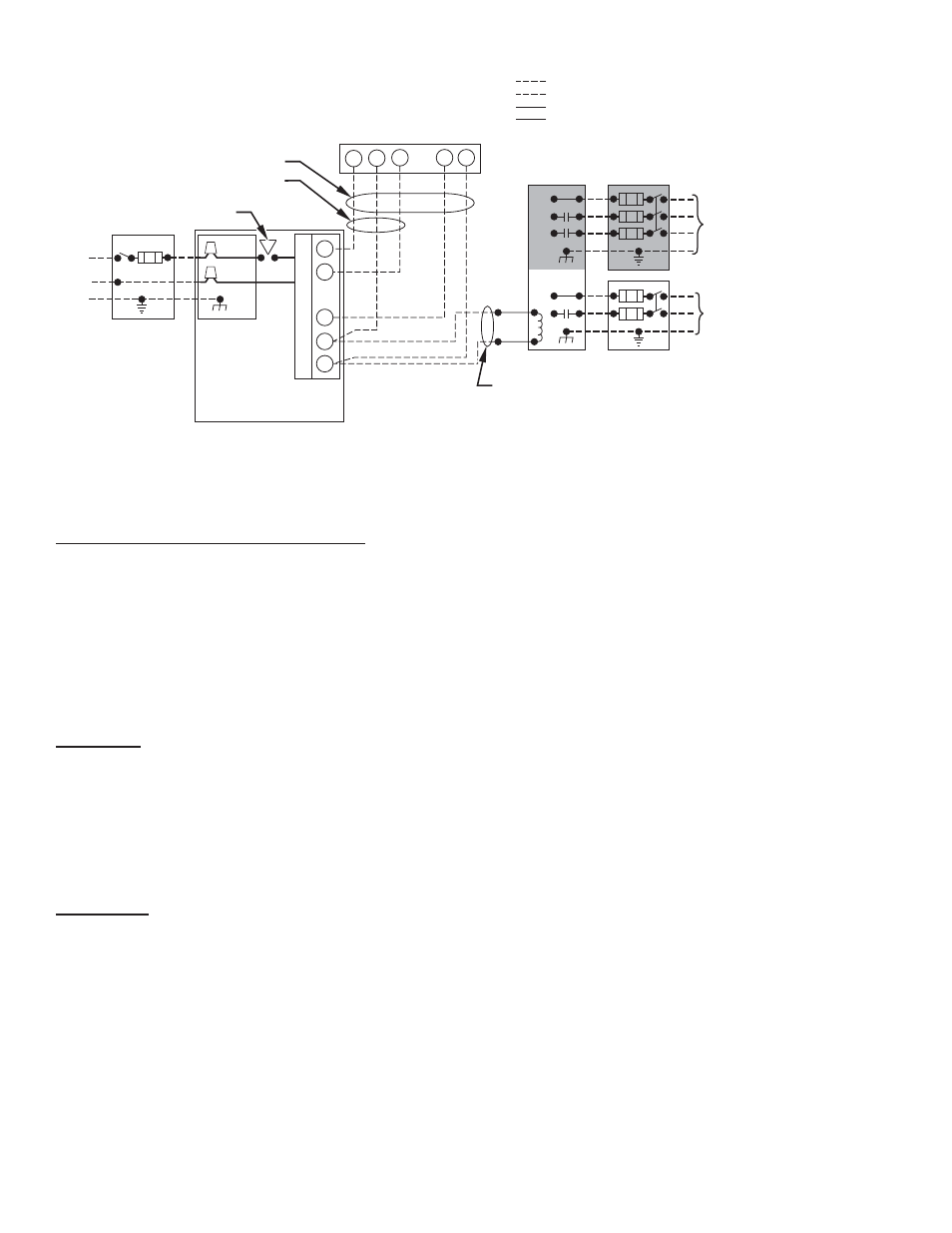

BX CABLE INSTALLATION IN FURNACE J-BOX

1. Remove cover from J-Box.

2. Route BX cable into 7/8-inch diameter hole in J-Box.

3. Secure BX cable to J-Box bracket with connectors approved

for the type of cable used.

4. Secure field ground wire to green ground screw on J-Box

bracket.

5. Connect line voltage leads as shown in Fig. 25.

6. Reinstall cover to J-Box. Do not pinch wires between cover

and bracket.

24-V WIRING

Make field 24-v connections at the 24-v terminal strip. (See Fig.

24.) Connect terminal Y as shown in Fig. 25 for proper cooling

operation. Use only AWG No. 18, color-coded, copper thermostat

wire.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the control. Any direct shorts during installation, service, or

maintenance could cause this fuse to blow. If fuse replacement is

required, use ONLY a 3-amp fuse of identical size.

ACCESSORIES

1. Electronic Air Cleaner (EAC)

Connect an accessory Electronic Air Cleaner (if used) using

1/4-in female quick connect terminals to the two male 1/4-in

quick-connect terminals on the control board marked EAC-1

and EAC-2. The terminals are rated for 115 VAC, 1.0 amps

maximum and are energized during blower motor operation.

(See Fig. 24.)

2. Humidifier (HUM)

Connect an accessory 24 VAC, 0.5 amp maximum humidifier

(if used) to the 1/4-in male quick-connect HUM terminal and

C

OM

-24V screw terminal on the control board thermostat strip.

The HUM terminal is energized when pressure switch (PRS)

closes. (See Fig. 24.)

NOTE:

A field-supplied, 115-v controlled relay connected to

EAC terminals may be added if humidifier operation is desired

during blower operation.

NOTE:

DO NOT connect furnace control HUM terminal to HUM

(humidifier) terminal on Thermidistat™, Zone Controller or simi-

lar device. See Thermidistat™, Zone Controller, thermostat, or

controller manufacturer’s instructions for proper connection.

VENTING

The furnace shall be connected to a listed factory built chimney or

vent or a clay-tile lined masonry or concrete chimney. Venting into

an unlined masonry chimney or concrete chimney is prohibited.

When an existing Category I furnace is removed or replaced, the

original venting system may no longer be sized to properly vent

the attached appliances. An improperly sized Category I venting

system could cause the formation of condensate in the furnace and

vent, leakage of condensate and combustion products, and spillage

of combustion products into the living space.

Fig. 25—Heating and Cooling Application Wiring Diagram with 1–Stage Thermostat

A99440

115-V FIELD-

SUPPLIED

DISCONNECT

AUXILIARY

J-BOX

24-V

TERMINAL

BLOCK

THREE-WIRE

HEATING-ONLY

FIVE WIRE

NOTE 1

NOTE 2

FIELD-SUPPLIED

DISCONNECT

CONDENSING

UNIT

TWO

WIRE

FURNACE

C

O

N

T

R

O

L

R

G

COM

W

C

R

G

Y

GND

GND

FIELD 24-V WIRING

FIELD 115-, 208/230-, 460-V WIRING

FACTORY 24-V WIRING

FACTORY 115-V WIRING

208/230- OR

460-V

THREE

PHASE

208/230-V

SINGLE

PHASE

BLOWER DOOR SWITCH

WHT

BLK

WHT

BLK

NOTES:

Connect Y-terminal in furnace as shown for proper blower operation.

Some thermostats require a "C" terminal connection as shown.

If any of the original wire, as supplied, must be replaced, use

same type or equivalent wire.

W

Y/Y2

GND

THERMOSTAT

TERMINALS

1.

2.

3.

22

→

→

→

→