Bryant Induced-Combustion 4-Way Multipoise 310AAV User Manual

Page 25

4. The input rating of each space heating appliance is greater

than the minimum input rating given in Table B for the local

99% Winter Design Temperature. Chimneys having internal

areas greater than 38 square inches require furnace input

ratings greater than the input ratings of these furnaces. See

footnote at bottom of Table B, and

5. The authority having jurisdiction approves.

If all of these conditions cannot be met, an alternative venting

design shall be used, such as the listed chimney adapter kit with

these furnaces listed for use with the kit, a listed chimney-lining

system, or a Type-B common vent.

Inspections before the sale and at the time of installation will

determine the acceptability of the chimney or the need for repair

and/or (re)lining. Refer to Fig. 26 to perform a chimney inspection.

If the inspection of a previously used tile-lined chimney:

a. Shows signs of vent gas condensation, the chimney should

be relined in accordance with local codes and the authority

having jurisdiction. The chimney should be relined with a

listed metal liner, Type-B vent, or a listed chimney adapter

kit shall be used to reduce condensation. If a condensate

drain is required by local code, refer to the NFGC, Section

10.9 for additional information on condensate drains.

b. Indicates the chimney exceeds the maximum permissible

size in the tables, the chimney should be rebuilt or relined

to conform to the requirements of the equipment being

installed and the authority having jurisdiction.

A chimney without a clay tile liner, which is otherwise in good

condition, shall be rebuilt to conform to ANSI/NFPA 211 or be

lined with a UL listed (ULC listed in Canada) metal liner or UL

listed Type-B vent. Relining with a listed metal liner or Type-B

vent is considered to be a vent-in-a-chase.

If a metal liner or Type-B vent is used to line a chimney, no other

appliance shall be vented into the annular space between the

chimney and the metal liner.

APPLIANCE APPLICATION REQUIREMENTS

Appliance operation has a significant impact on the performance

of the venting system. If the appliances are sized, installed,

adjusted, and operated properly, the venting system and/or the

appliances should not suffer from condensation and corrosion. The

venting system and all appliances shall be installed in accordance

with applicable listings, standards, and codes.

The furnace should be sized to provide 100 percent of the design

heating load requirement plus any margin that occurs because of

furnace model size capacity increments. Heating load estimates

can be made using approved methods available from Air Condi-

tioning Contractors of America (Manual J); American Society of

Heating, Refrigerating, and Air-Conditioning Engineers; or other

approved engineering methods. Excessive oversizing of the fur-

nace could cause the furnace and/or vent to fail prematurely.

When a metal vent or metal liner is used, the vent must be in good

condition and be installed in accordance with the vent manufac-

turer’s instructions.

To prevent condensation in the furnace and vent system, the

following precautions must be observed:

1. The return-air temperature must be at least 60°F db except for

brief periods of time during warm-up from setback at no lower

than 55°F db or during initial start-up from a standby

condition.

2. Adjust the gas input rate per the installation instructions. Low

gas input rate causes low vent gas temperatures, causing

condensation and corrosion in the furnace and/or venting

system. Derating is permitted only for altitudes above 2000 ft.

3. Adjust the air temperature rise to the midpoint of the rise range

or slightly above. Low air temperature rise can cause low vent

gas temperature and potential for condensation problems.

→

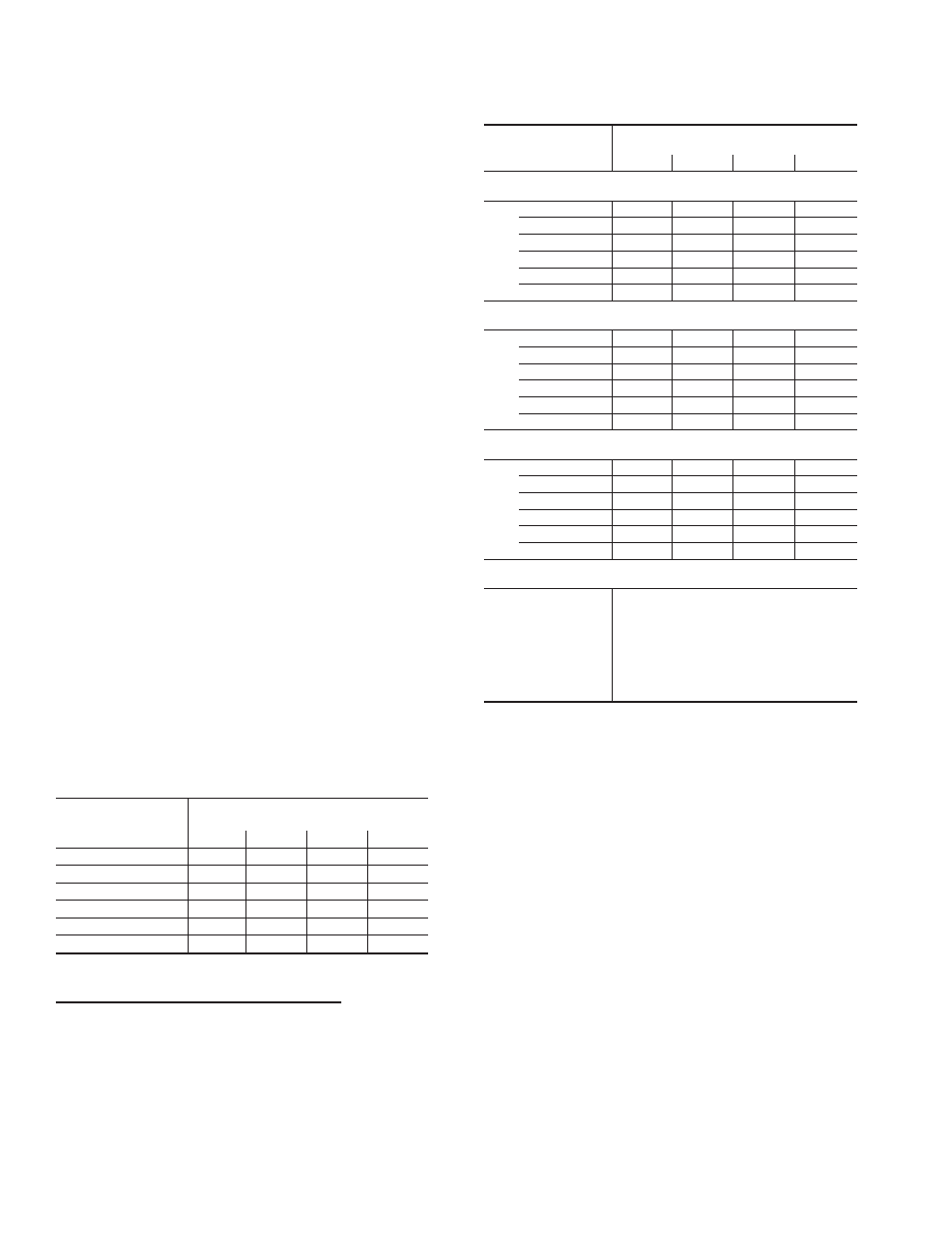

Exterior Masonry Chimney FAN + NAT

Installations with Type-B Double-Wall Vent

Connectors

©NFPA & AGA

Table A—Combined Appliance Maximum Input

Rating in Thousands of BTU per Hour

VENT HEIGHT (FT)

INTERNAL AREA OF CHIMNEY

(SQ. IN.)

12

19

28

38

6

74

119

178

257

8

80

130

193

279

10

84

138

207

299

15

NR

152

233

334

20

NR

NR

250

368

30

NR

NR

NR

404

Table B—Minimum Alowable Input Rating of

Space-Heating Appliance in

Thousands of BTU per Hour

VENT

HEIGHT (FT)

INTERNAL AREA OF CHIMNEY

(SQ. IN.)

12

19

28

38

Local 99% Winter Design

Temperature: 17 to 26 degrees F*

17

to

26°F

6

0

55

99

141

8

52

74

111

154

10

NR

90

125

169

15

NR

NR

167

212

20

NR

NR

212

258

30

NR

NR

NR

362

Local 99% Winter Design

Temperature: 5 to 16 degrees F*

5

to

16°F

6

NR

78

121

166

8

NR

94

135

182

10

NR

111

149

198

15

NR

NR

193

247

20

NR

NR

NR

293

30

NR

NR

NR

377

Local 99% Winter Design

Temperature: -10 to 4 degrees F*

-10

to

4°F

6

NR

NR

145

196

8

NR

NR

159

213

10

NR

NR

175

231

15

NR

NR

NR

283

20

NR

NR

NR

333

30

NR

NR

NR

NR

Local 99% Winter Design

Temperature: -11 degrees F or lower*

-11°F

or

lower

Not recommended for any vent

configuration

*The 99% Winter Design Dry-Bulb (db) temperatures are found in the 1993

ASHRAE Fundamentals Handbook, Chapter 24, Table 1 (United States) and

2 (Canada), or use the 99.6% heating db temperatures found in the 1997 or

2001 ASHRAE Fundamentals Handbook, Climatic Design Information chap-

ter, Table 1A (United States) and 2A (Canada).

24